Application process for brazing ZrO2 and TC4 by using NiCrWB powder brazing material

A brazing material and brazing technology, applied in the direction of welding/welding/cutting articles, welding/cutting media/materials, welding media, etc., can solve the problem that the shearing effect is not optimal, the mechanical properties of brazed joints are poor, Solve problems such as large residual stress in the brazing joint, achieve good connection performance, low cost, and improve the effect of grain boundary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

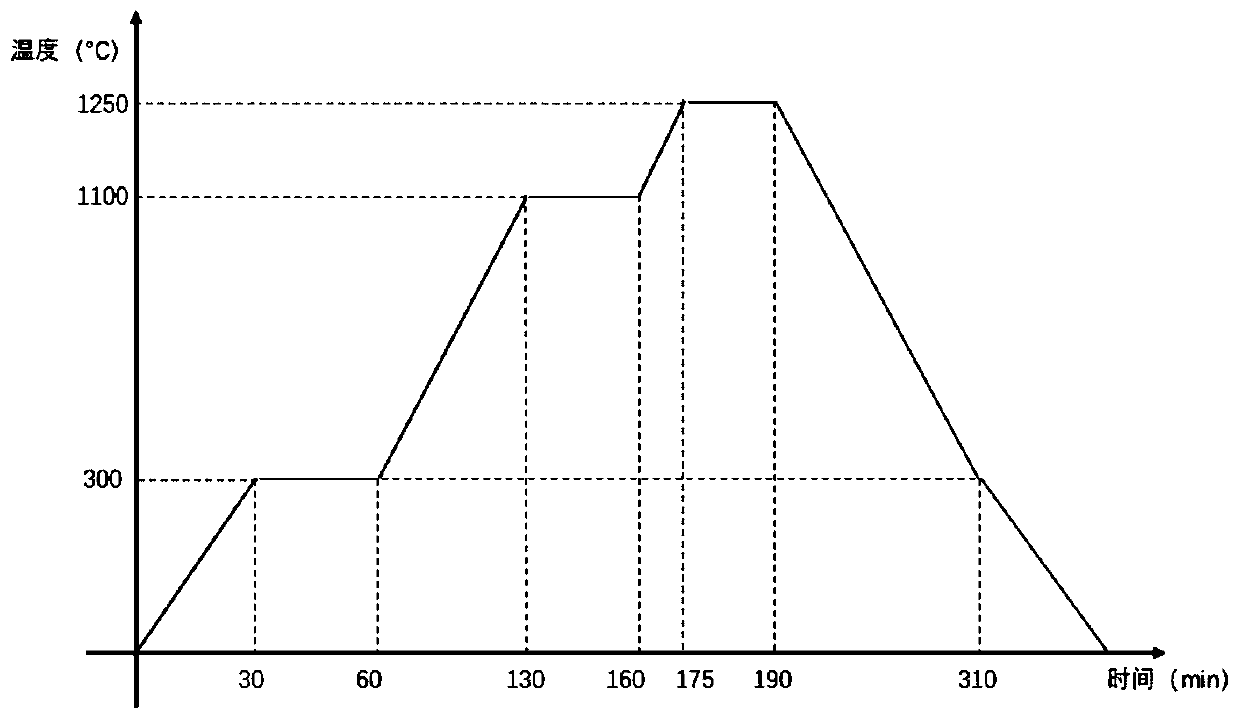

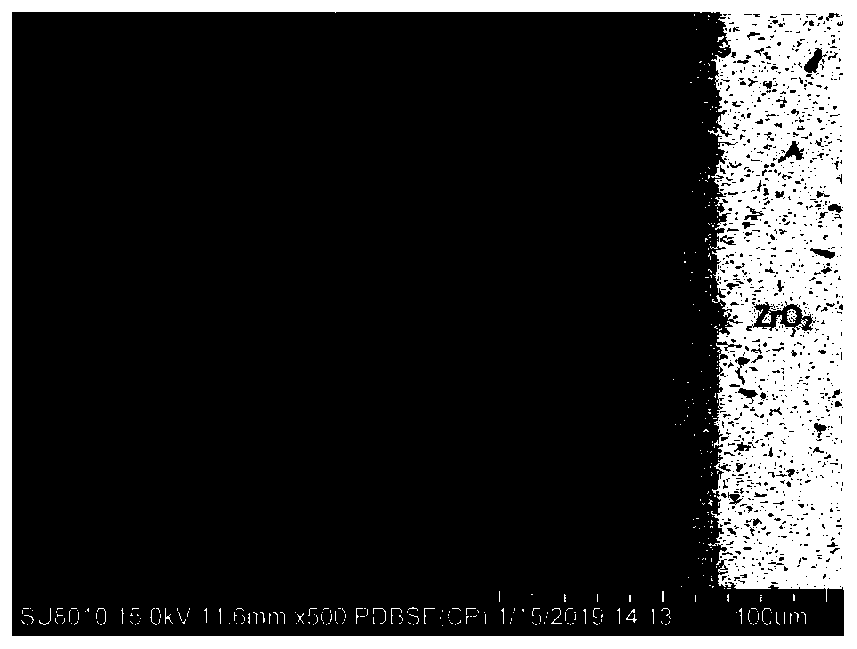

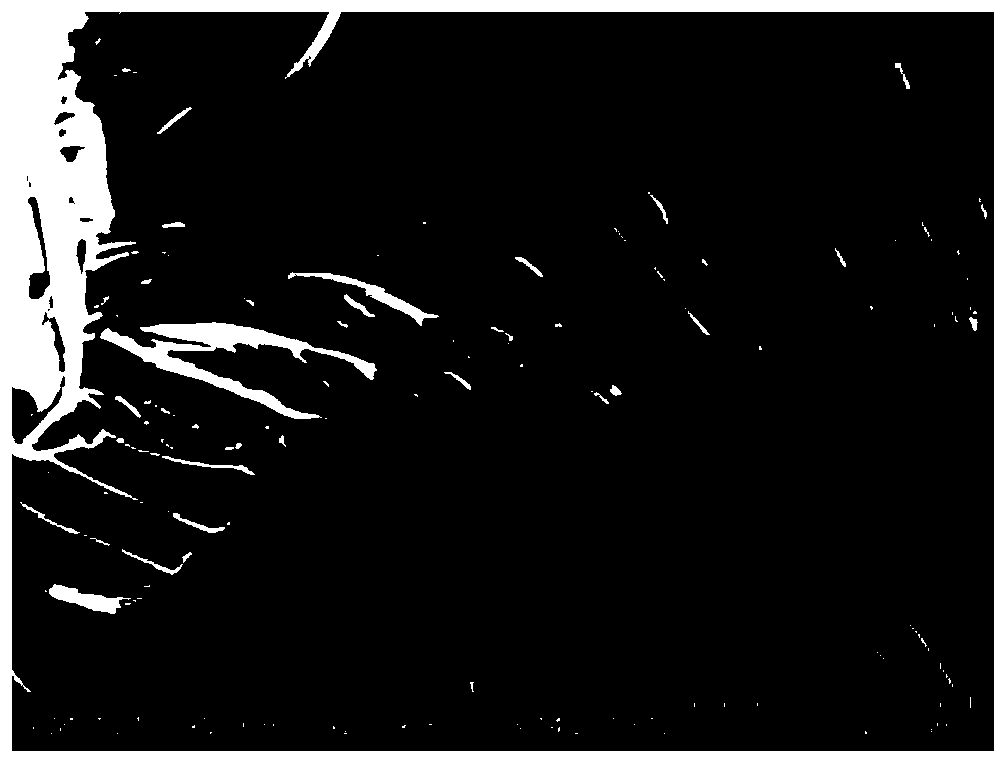

[0030] Brazing of ZrO with NiCrWB powder brazing material 2 With the application process of TC4, the raw material composition of NiCrWB powder: 15.0wt% Cr, 15wt% Ni, 4.0wt% W, 8.0wt% B, the balance is Ni, and its brazing process includes the following steps:

[0031] 1) Take the TC4 plate with a purity of 99.99% and process it into a 4mm×4mm×4mm cube by wire cutting, and take the 4mm×4mm×4mm ZrO purchased from the manufacturer 2 , use sandpaper to polish the two connecting surfaces respectively until the surface is smooth, and then use alcohol for ultrasonic cleaning;

[0032] 2) Pour the NiCrWB powder brazing material and binder into a mortar, grind the NiCrWB powder brazing material and the binder at a mass ratio of 19:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com