Process for producing compatibilized resin, thermosetting resin composition, prepreg, and laminate

A resin composition, thermosetting technology, applied in the fields of thermosetting resin compositions, prepregs and laminates, can solve poor curing reactivity, heat resistance, insufficient reliability, processability, curing reactivity and toughness Low thermal expansion, excellent drilling processability, and no environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Next, the present invention is explained in more detail by the following examples, but these examples do not limit the present invention in any way.

[0098] In addition, the copper clad laminated board obtained by the following Example and the comparative example was measured and evaluated by the following method.

[0099] (1) Copper foil adhesion (copper foil peel strength)

[0100] The copper-clad laminate was immersed in a copper etchant to form a 1-cm-wide copper foil to prepare an evaluation board, and the adhesiveness (peel strength) of the copper foil was measured using a tensile tester.

[0101] (2) Glass transition temperature (Tg)

[0102] Prepare a 5 mm square evaluation substrate obtained by immersing the copper-clad laminate in a copper etchant to remove the copper foil, and evaluate by observing the thermal expansion characteristics in the plane direction of the evaluation substrate using a TMA tester (manufactured by DuPont, TMA2940) .

[0103] (3) So...

manufacture example 1

[0115] Production Example 1: Production of Compatible Resin (A1-1)

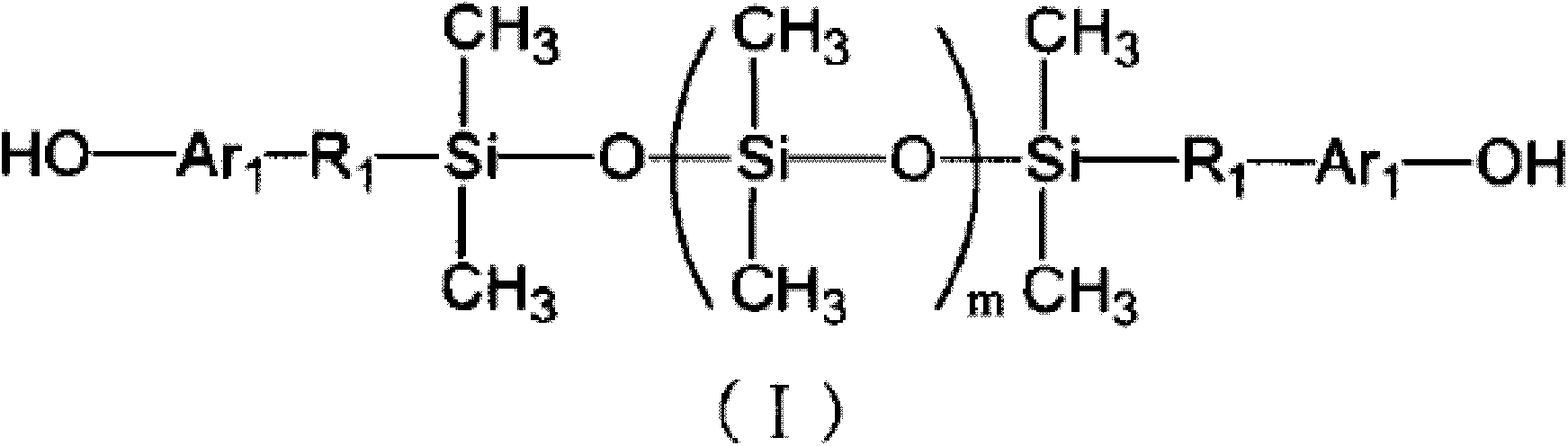

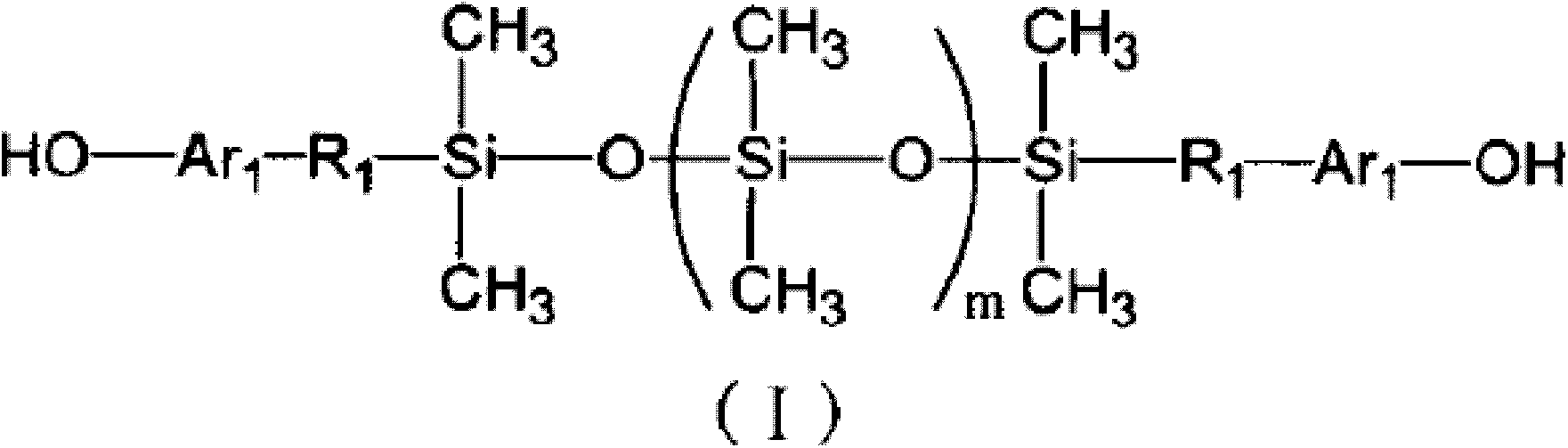

[0116] 600.0 g of bisphenol A type cyanate resin (manufactured by Lonza Japan Ltd.: trade name Primaset BADCy), 200.0 g of siloxane resin represented by the following formula (V) (manufactured by Shin-Etsu Chemical Co., Ltd.: trade name X-22-1821, hydroxyl equivalent weight: 1,600), 200.0 g of biphenyl type epoxy resin (Japan Epoxy Resins Co. , Ltd.: trade name YX-4000, epoxy equivalent 186), and 1000.0 g of toluene. Then, the temperature was raised to 120°C while stirring, and after confirming that the solid content of the resin was dissolved into a uniform solution, 0.01 g of an 8% by mass mineral spirits solution of zinc naphthenate was added, and the reaction was carried out at about 110°C for 4 hours. . Then, it was cooled to room temperature to obtain a solution of compatible resin (A1-1).

[0117] Take out a small amount of this reaction solution, carry out GPC measurement (converted into polystyren...

manufacture example 2

[0120] Production Example 2: Production of Compatible Resin (A1-2)

[0121] In a reaction vessel with a volume of 3 liters that can be heated and cooled with a thermometer, a stirring device, and a reflux cooling pipe, 800.0 g of novolak type cyanate resin (manufactured by Lonza Japan Ltd.: trade name Primaset PT-15) was dropped into , weight average molecular weight 500-1,000), and 100.0 g of a siloxane resin represented by the following formula (VI) (manufactured by Shin-Etsu Chemical Co., Ltd.: trade name KF-6003, hydroxyl equivalent weight: 2800), 100.0 g of naphthol arane Base / cresol copolymerization type epoxy resin (manufactured by Nippon Kayaku Co., Ltd.: trade name NC-7000L, epoxy equivalent: 230) and 1000.0 g of toluene. Then, the temperature was raised to 120° C. while stirring, and after confirming that the resin solid content was dissolved into a uniform solution, 0.01 g of an 8% by mass mineral spirits solution of zinc naphthenate was added, and the reaction was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com