Method for pretreating lime kiln tail gas and improving carbon dioxide concentration of tail gas

A technology of lime kiln and pretreatment, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., which can solve the problems of unsatisfactory process requirements, environmental pollution, and single impurity treatment process, and achieve a wide range of impurities and avoid Intense corrosion, the effect of reducing system investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

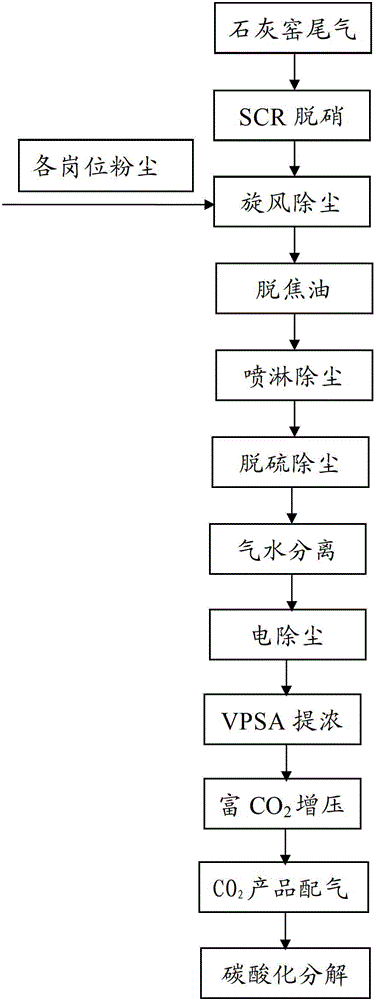

[0076] The tail gas from the lime kiln flue gas collection system (where CO 2 The volume concentration is 15%, the temperature is not higher than 240°C, and the dust content is 5000mg / Nm 3 ) into the SCR device, according to NH 3 : NO x The ratio (molar ratio) of 1.05 is sprayed into ammonia water, and the space velocity under normal pressure is 2500h -1 When, denitrification is carried out to remove NOx in the exhaust gas.

[0077] Then, the tail gas and the dust collected by each post of limestone production are respectively input into a cyclone dust collector through the pipeline, and the wind speed is 20m / s, and the cyclone dust removal is implemented. After that, the tail gas obtained by the cyclone dust removal is input into the tar remover through the pipeline, and the tar is intercepted and removed by the oil trap in the device.

[0078] The tar-removed tail gas will be used at 20000m 3 / h flow is input from the bottom of a spray dedusting tower into the spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com