Ash cooling device for garbage burning

A waste incineration ash and cooling device technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of drying heat consumption, high failure rate, and reducing the service life of refractory materials in waste incineration devices, achieving simple structure, The effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

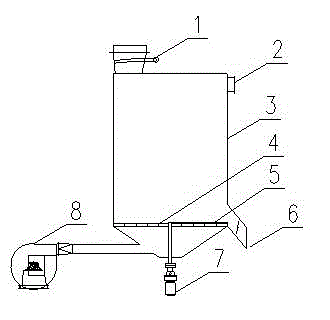

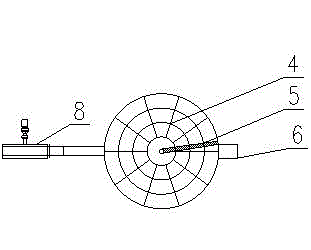

[0028] The specific structure of a waste incineration ash cooling device is as follows: figure 1 , which consists of slag inlet (1), hot air outlet (2), cooling device housing (3), inflatable chassis (4), slag retaining plate (5), slag discharge port (6), transmission motor (7) and Cooling blower fan (8) etc. are formed. The garbage is discharged after being incinerated by the incineration device, and the ash enters the cooling device (3) through the slag inlet (1), and the cooling air is blown into the inflatable chassis (4) of the cooling device by the cooling fan (8), and the cooled ash is blocked The slag plate (5) is scraped into the slag outlet (6) and then discharged from the cooling device. The hot air after the heat exchange between the cold air and the hot ash is discharged from the hot air outlet (2), and then returns to the waste incineration device or the air chamber for waste drying. Dry and incinerate, or use for other purposes. By controlling the rotating spe...

Embodiment 2

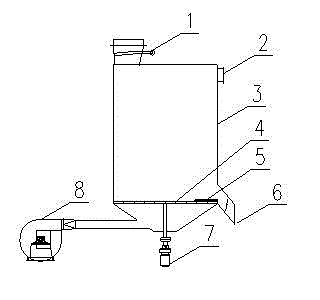

[0031] The specific structure of a waste incineration ash cooling device is as follows: image 3 , which consists of slag inlet (1), hot air outlet (2), cooling device housing (3), inflatable chassis (4), slag retaining plate (5), slag discharge port (6), transmission motor (7) and Cooling blower fan (8) etc. are formed. The garbage is discharged after being incinerated by the incineration device, and the ash enters the cooling device (3) through the slag inlet (1), and the cooling air is blown into the inflatable chassis (4) of the cooling device by the cooling fan (8), and the cooled ash is blocked The slag plate (5) is scraped into the slag outlet (6) and then discharged from the cooling device. The hot air after the heat exchange between the cold air and the hot ash is discharged from the hot air outlet (2), and then returns to the waste incineration device or the air chamber for waste drying. Dry and incinerate, or use for other purposes. By controlling the rotating spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com