Method for extracting camellia oleosa seed oil by weak acid aqueous solution

A technology of camellia oil and camellia seeds, which is applied in the directions of oil/fat production, fat production, etc., can solve the problems that extraction technology cannot be applied on a large scale, organic solvents are flammable and explosive, and the oil yield of camellia oil is low. To achieve the effect of easy mass production, convenient comprehensive utilization and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

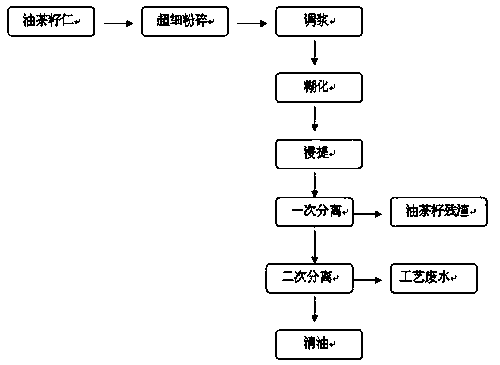

Image

Examples

Embodiment 1

[0022] Weigh 200g of tea seed kernels and ultrafinely pulverize them to obtain a material with a particle size of 60-80μm, add phosphoric acid aqueous solution at a solid-to-liquid ratio of 1:6, and gelatinize at 92-95°C for 40min. After the gelatinized slurry was cooled to room temperature, the pH was adjusted to 4.5, and then stirred and leached for 2 hours at a temperature of 60°C. Take the extract and centrifuge it at 4500r / min for 10min, absorb the oil-water mixture in the upper layer, centrifuge the mixture again at 6500r / min for 10min, and pour out the supernatant oil. The detected oil extraction rate was 90.16%.

Embodiment 2

[0024] Weigh 200g of tea seed kernels and ultrafinely pulverize them to obtain a material with a particle size of 40-60μm, add phosphoric acid aqueous solution at a solid-to-liquid ratio of 1:8, and gelatinize at 92-95°C for 40min. After cooling the gelatinized slurry to room temperature, adjust its pH to 4, and then leaching with stirring for 1.5 h at a temperature of 60°C. The extract was centrifuged at 4000r / min for 12min, and the upper oil-water mixture was absorbed, and the mixture was centrifuged again at 8000r / min for 10min, and the supernatant clear oil was poured out. The detected oil extraction rate was 93.62%.

Embodiment 3

[0026] Weigh 300g of tea seed kernels and ultrafinely pulverize them to obtain a material with a particle size of 60-80μm, add phosphoric acid aqueous solution at a solid-to-liquid ratio of 1:4, and conduct gelatinization at 65-70°C for 60min. After the gelatinized slurry was cooled to room temperature, the pH was adjusted to 5, and then stirred and leached for 3 hours at a temperature of 60°C. The extract was centrifuged at 5000r / min for 20min, the upper oil-water mixture was absorbed, the mixture was centrifuged again at 7500r / min for 15min, and the supernatant oil was poured out. The detected oil extraction rate was 88.94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com