Flame-retardant thermal-conductive plastic composition

A technology of thermally conductive plastics and compositions, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as non-compliance with fire protection requirements, and achieve the effects of excellent stability, excellent heat dissipation performance, and low thermal impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

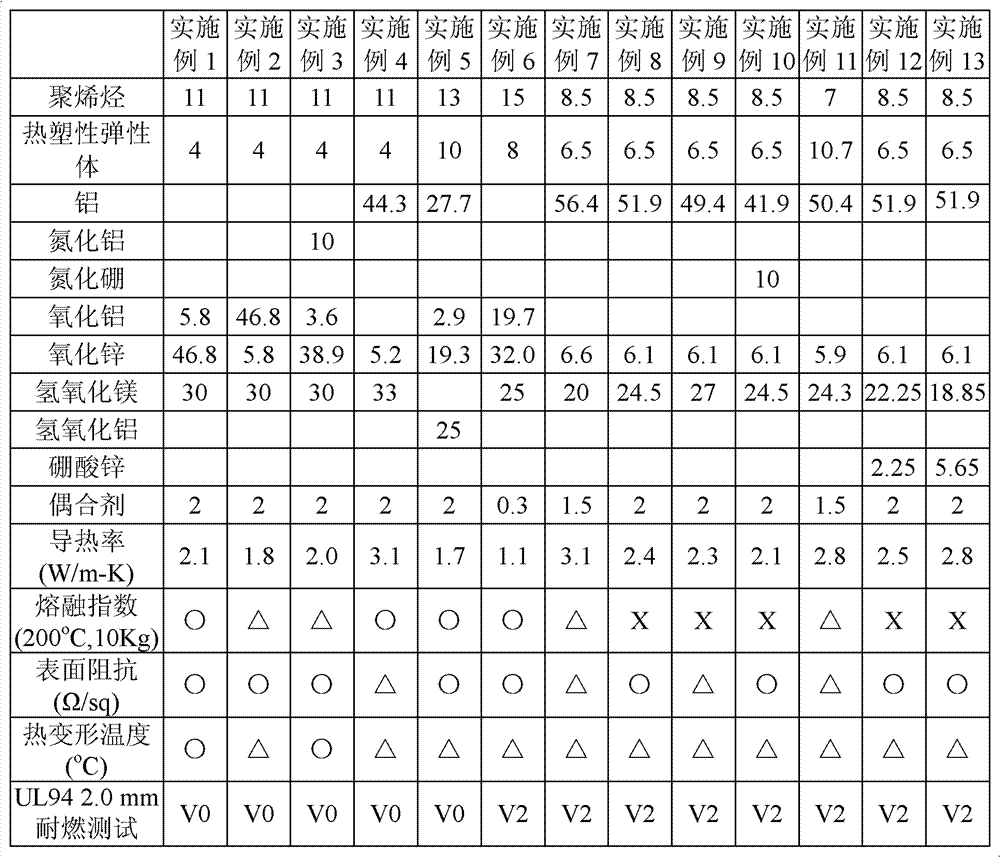

[0049] Please refer to Table 1 for the proportions and measurement results of the components of Examples 1 to 13:

[0050] Table 1: The formula and physical property table of embodiment 1-13

[0051]

[0052] Can find out the proportioning of different embodiments of the present invention from the table. Wherein, polyolefin, thermoplastic elastomer, aluminum, aluminum nitride, boron nitride, aluminum oxide, zinc oxide, magnesium hydroxide, aluminum hydroxide, zinc borate or coupling agent are expressed as weight percent.

[0053] The production methods of the examples are all to put polyolefin, thermoplastic elastomer, inorganic filler, fireproofing agent and coupling agent into the feeding hopper respectively, knead and granulate by using a co-rotating twin-screw extruder. Wherein, the screw speed is controlled at 150 to 200 rpm. After the pellets are obtained, injection molding is performed with an injection molding machine at a screw heating temperature of 210° C. and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com