Multifunctional composite material and application thereof

A composite material and multi-functional technology, applied in special decorative structures, synthetic resin layered products, decorative arts, etc., to achieve strong impact resistance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

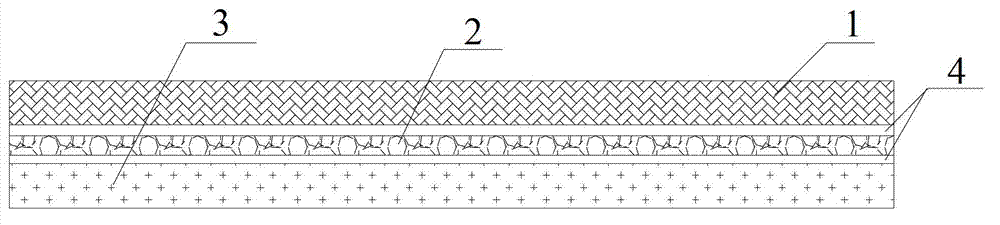

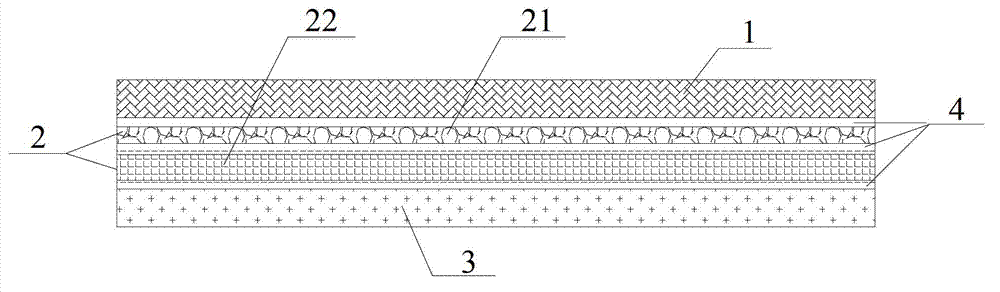

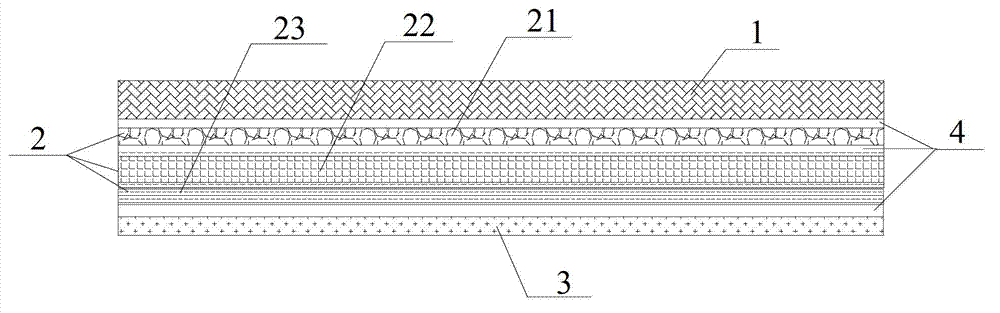

[0035] The above-mentioned composite material is prepared by first coating the lower outer surface layer 3, the middle layer 2, and the upper outer surface layer 1 whose lower surface is coated with an adhesive coating or film on the upper surface. Stacked well, and then use a vacuum hot laminator to heat press and cool down.

[0036] Since the upper outer surface layer 1 and the lower outer surface layer 3 are formed by transparent polymers, at least one surface of the textile fabric 21 contained in the middle layer 2 has an artistic pattern, and the adhesive for hot pressing is a light-transmitting polymer, so , the obtained composite material has multiple functions such as high light transmittance, artistic decoration, light weight, high strength, etc., and the processing is simple and convenient, and various complex artistic patterns can be realized without complicated painting process, not only decorative The effect is obvious, and energy saving and environmental protecti...

Embodiment 1

[0044] The composition of the composite material prepared in this embodiment is as follows:

[0045] ① The upper and lower outer surface layers are made of transparent polycarbonate (PC) boards with a size of 2000mm×2200mm×3.0mm;

[0046] ②The middle layer is a high-density three-dimensional carbon fiber cloth, one surface has small twill squares, and the other surface is coated by vacuum magnetron sputtering. The film material is composed of titanium nitride + metallic silver + aluminum-titanium alloy, and the film thickness is 100μm, reflectivity up to 80%;

[0047] ③The thickness of the EVA hot melt adhesive film is controlled at 25μm.

[0048] The preparation of the composite material comprises the following steps:

[0049] 1. Vacuum magnetron sputtering coating treatment on the surface of textile fabrics

[0050] The high-density three-dimensional carbon fiber cloth is used as the substrate, and it enters the No. 1 reaction chamber of the magnetron sputtering coating m...

Embodiment 2

[0056] The composition of the composite material prepared in this embodiment is as follows:

[0057] ①The upper outer surface layer adopts a transparent polycarbonate (PC) board with a size of 2000mm×2200mm×3.0mm, and the lower outer surface layer adopts a transparent polycarbonate (PC) board with a size of 2000mm×2200mm×1.5mm;

[0058] ②The middle layer is high-density glass fiber cloth, one surface has small twill squares, and the other surface is coated by vacuum magnetron sputtering. The film material is composed of titanium nitride + metal silver + titanium nitride carbide.

[0059] ③The thickness of the EVA hot melt adhesive film is controlled at 5 μm.

[0060] The preparation of the composite material comprises the following steps:

[0061] 1. Vacuum magnetron sputtering coating treatment on the surface of textile fabrics

[0062] With high-density glass fiber cloth as the substrate, it enters into the No. 1 reaction chamber of the magnetron sputtering coating machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com