Manufacturing process of flashy framed sand painting for decoration of distribution box

A distribution box and sand painting technology, which is applied in the field of sand painting, can solve the problems of poor light transmission effect and poor sand bonding effect of sand painting, so as to ensure human health, avoid contact with human body, and improve aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The production process of flashing and framed sand paintings for distribution box decoration consists of the following steps:

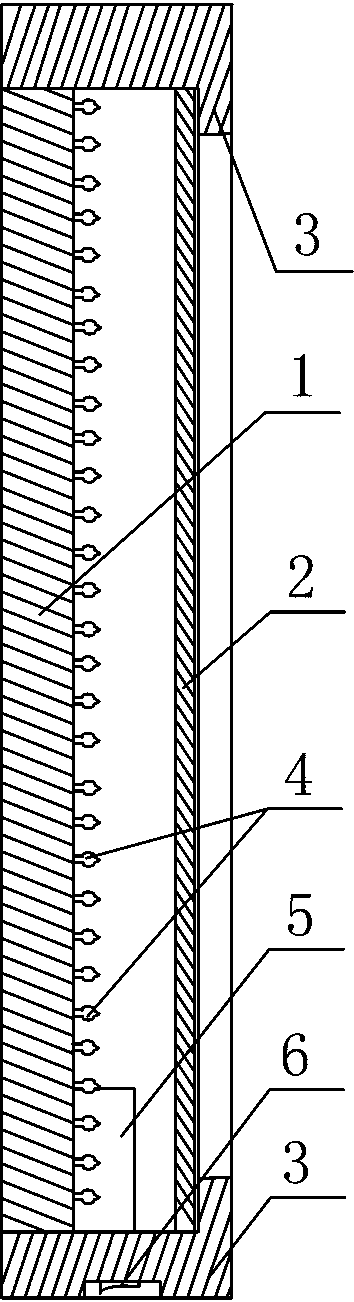

[0038] (1) Make a sand painting frame for the decoration of the distribution box according to the conventional method. The sand painting frame includes a bottom plate 1, an LED lantern 4 set on the bottom plate 1, a frame 3 set on the bottom plate 1, and a frame 3 A switch 6 connected to the LED lantern 4, and a power supply device 5 fixed on the base plate 1 to provide energy for the LED lantern 4;

[0039] The power supply device 5 is a rechargeable battery fixed on the base plate 1 and the LED lantern 4 provides energy, and the switch 6 between the LED lantern 4 and the rechargeable battery is fixed on the frame 3, as figure 1 shown.

[0040] (2) To make sand-painted glass plates, the specific steps are as follows,

[0041] (1) Use glass etchant to corrode the glass where the colored sand needs to be filled. The glass etchant is applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com