Automatic sand core production device

A production device and sand core technology, which is applied to casting molding equipment, parts of molding machines, metal processing equipment, etc., can solve the problems affecting the quality of castings, many types of molds, and sand core falling off, so as to improve the quality of sand cores and reduce Safety risk, effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

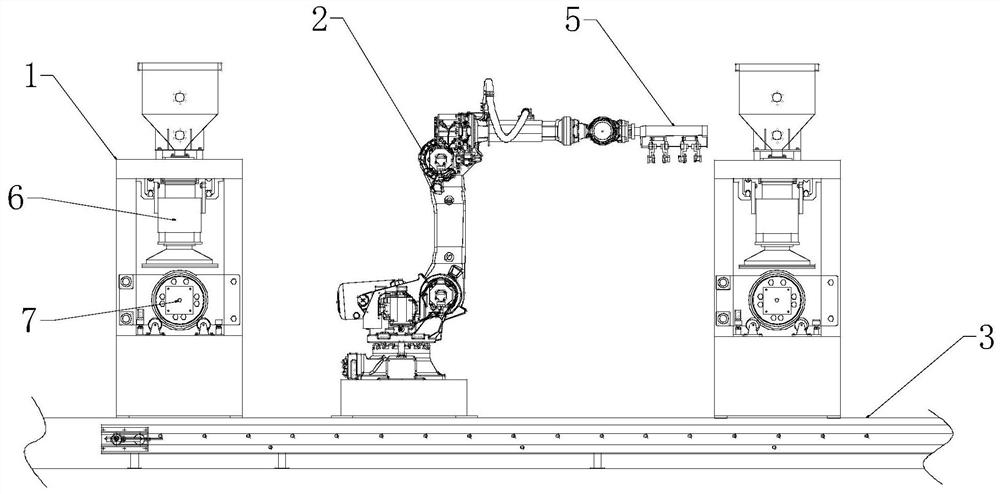

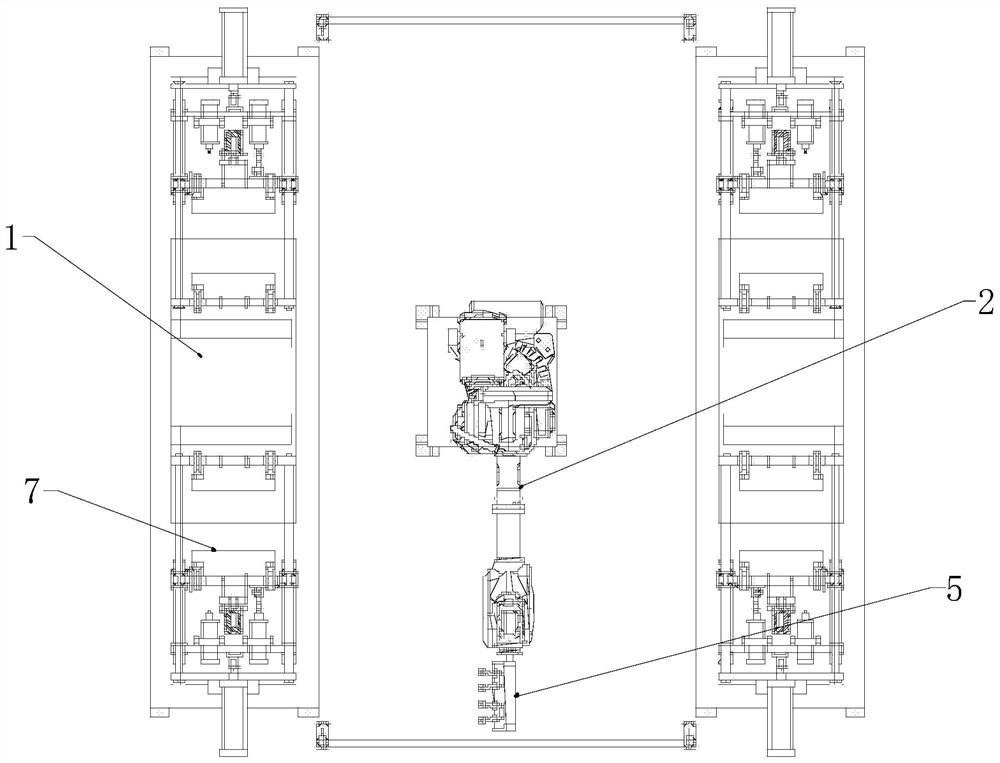

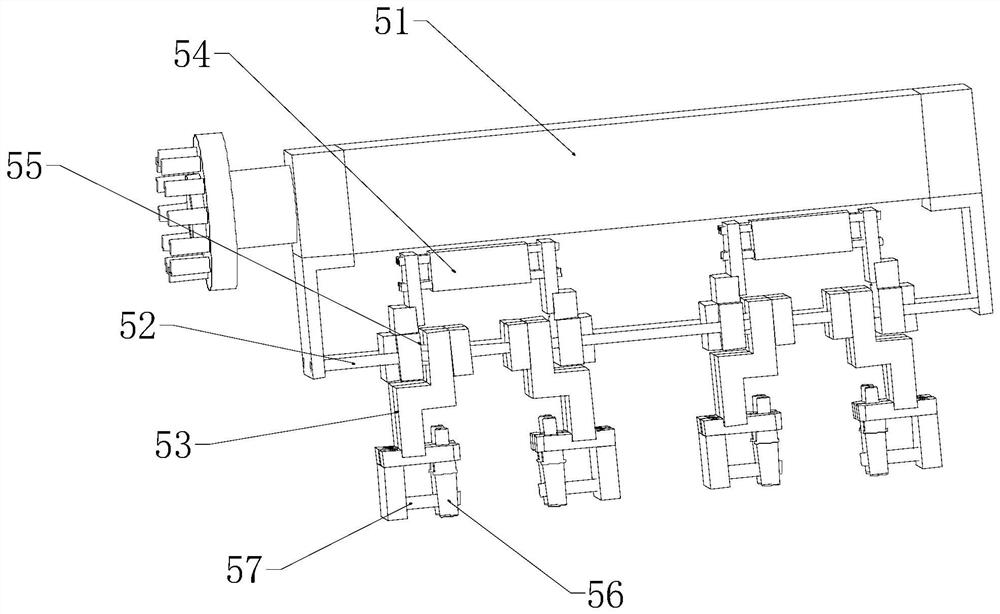

[0023] Figure 1-7 It shows an automatic sand core production device, including a core making machine 1, a mechanical arm 2 and a conveyor belt 3. After the core making machine 1 produces a sand core 4, the floating manipulator gripper arm 2 can transfer the sand core 4 to the conveyor belt. On the belt 3, the front end of the mechanical arm 2 is connected with a floating manipulator gripper 5, the floating manipulator gripper 5 includes a rotating shaft 51, a sliding bar 52, and a gripping jaw 53, the rotating shaft 51 is connected with the mechanical arm 2, and the sliding bar 52 is fixedly connected On the rotating shaft 51, the jaws 53 are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com