Manufacture method for monolithic integration titanium film thermal resistor tunable distributed feed back (DFB) laser

A DFB laser and manufacturing method technology, which is applied to lasers, laser parts, semiconductor lasers, etc., can solve problems such as complex processes, and achieve the effect of simplifying the manufacturing process and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

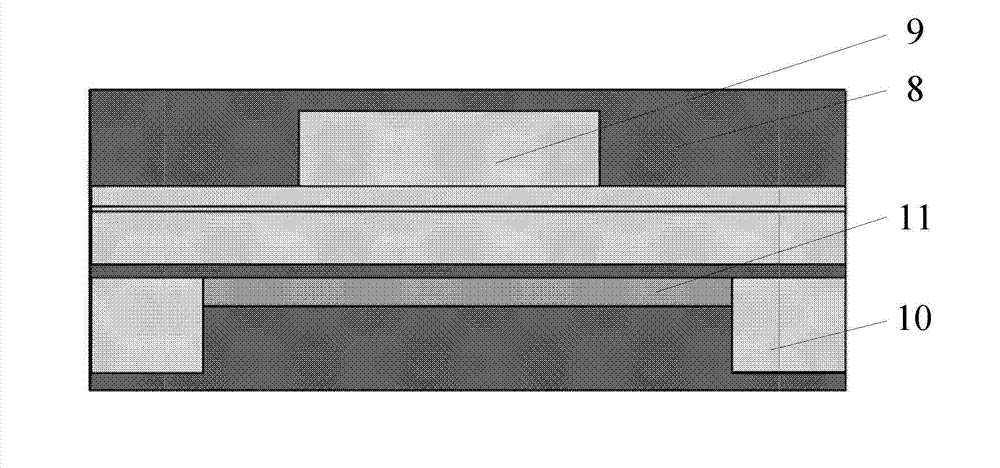

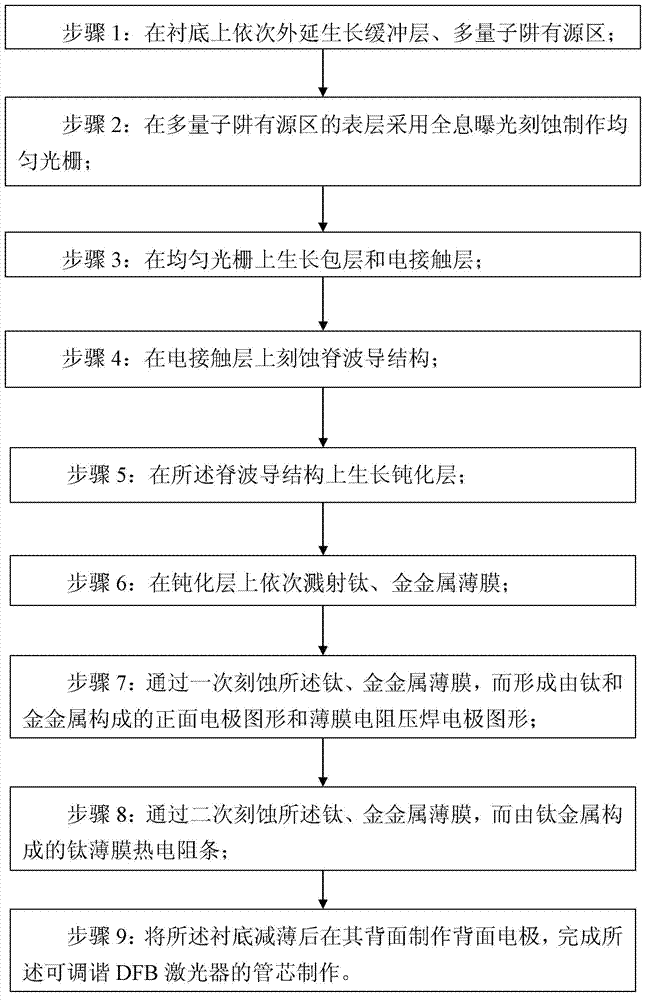

[0042] In a preferred embodiment of the present invention, the manufacturing method of the N-type substrate monolithically integrated titanium thin film thermal resistance tunable DFB laser comprises the following steps:

[0043] Select an N-type indium phosphide substrate 1 with a doping concentration of 5×10 17 cm -3 , the crystal plane is (100); the buffer layer 2, the multi-quantum well active region 3 and the electrical contact layer 4 are epitaxially grown sequentially on the N-type indium phosphide substrate 1, and the multi-quantum well active region 3 includes sequentially grown The lower waveguide layer 31, the core layer 32 and the upper waveguide layer 33; the material of the core layer 32 in the multi-quantum well active region 3 is InGaAsP, with a thickness of 70 nanometers.

[0044] Fabricate a uniform grating 4 on the surface layer of the multi-quantum well active region 3; grow a cladding layer 5 and an electrical contact layer 6 on the uniform grating 4; use...

Embodiment 2

[0048] In another preferred embodiment of the present invention, the manufacturing method of the N-type substrate monolithically integrated titanium thin film thermal resistance tunable DFB laser comprises the following steps:

[0049] Select an N-type indium phosphide substrate 1 with a doping concentration of 5×10 18 cm -3 , the crystal plane is (100); the buffer layer 2, the multi-quantum well active region 3 and the electrical contact layer 4 are epitaxially grown sequentially on the N-type indium phosphide substrate 1, and the multi-quantum well active region 3 includes sequentially grown The lower waveguide layer 31, the core layer 32 and the upper waveguide layer 33; the material of the core layer 32 in the multi-quantum well active region 3 is InGaAsP, with a thickness of 120 nanometers.

[0050] Fabricate a uniform grating 4 on the surface layer of the multi-quantum well active region 3; grow a cladding layer 5 and an electrical contact layer 6 on the uniform grating...

Embodiment 3

[0054] In another preferred embodiment of the present invention, the manufacturing method of the N-type substrate monolithically integrated titanium thin film thermal resistance tunable DFB laser comprises the following steps:

[0055] Select an N-type indium phosphide substrate 1 with a doping concentration of 2×10 18 cm -3 , the crystal plane is (100); the buffer layer 2, the multi-quantum well active region 3 and the electrical contact layer 4 are epitaxially grown sequentially on the N-type indium phosphide substrate 1, and the multi-quantum well active region 3 includes sequentially grown The lower waveguide layer 31, the core layer 32 and the upper waveguide layer 33; the material of the core layer 32 in the multi-quantum well active region 3 is InGaAsP, with a thickness of 100 nanometers.

[0056] Fabricate a uniform grating 4 on the surface layer of the multi-quantum well active region 3; grow a cladding layer 5 and an electrical contact layer 6 on the uniform grating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com