Anode material-nanometer vanadium iron manganese lithium phosphate of lithium ion battery and preparation method of anode material

A technology for lithium vanadium iron manganese phosphate and lithium ion batteries, which can be applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as low safety of oxide positive electrode materials, unstable structure of lithium manganese phosphate materials, and poor cycle performance , to achieve excellent cycle stability, reduce product cost, and shorten the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

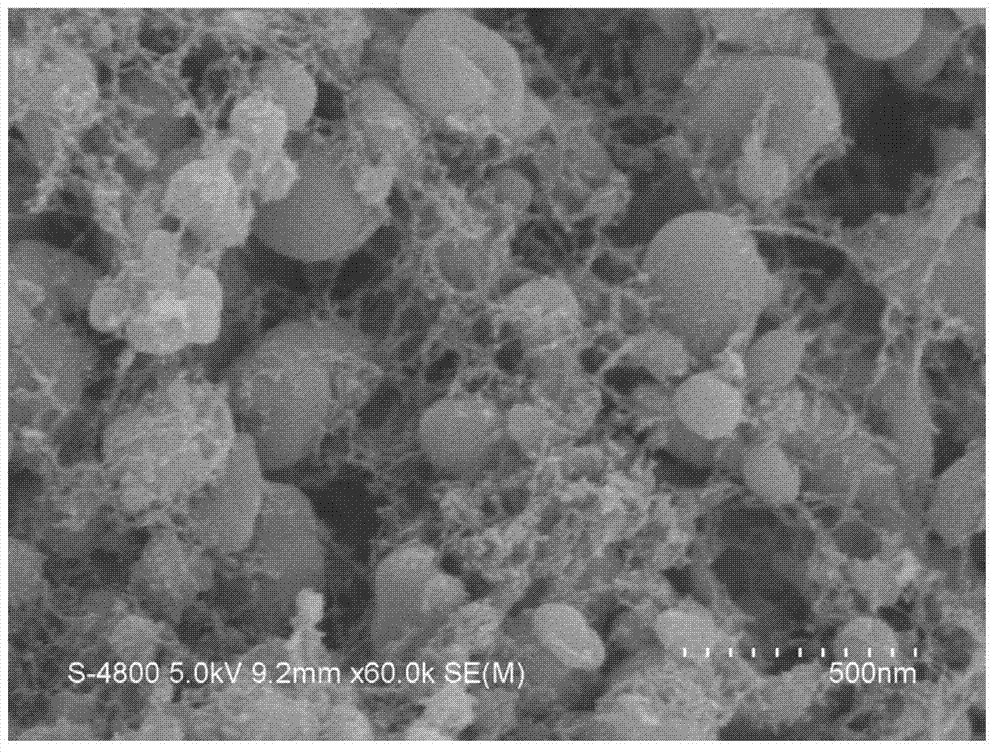

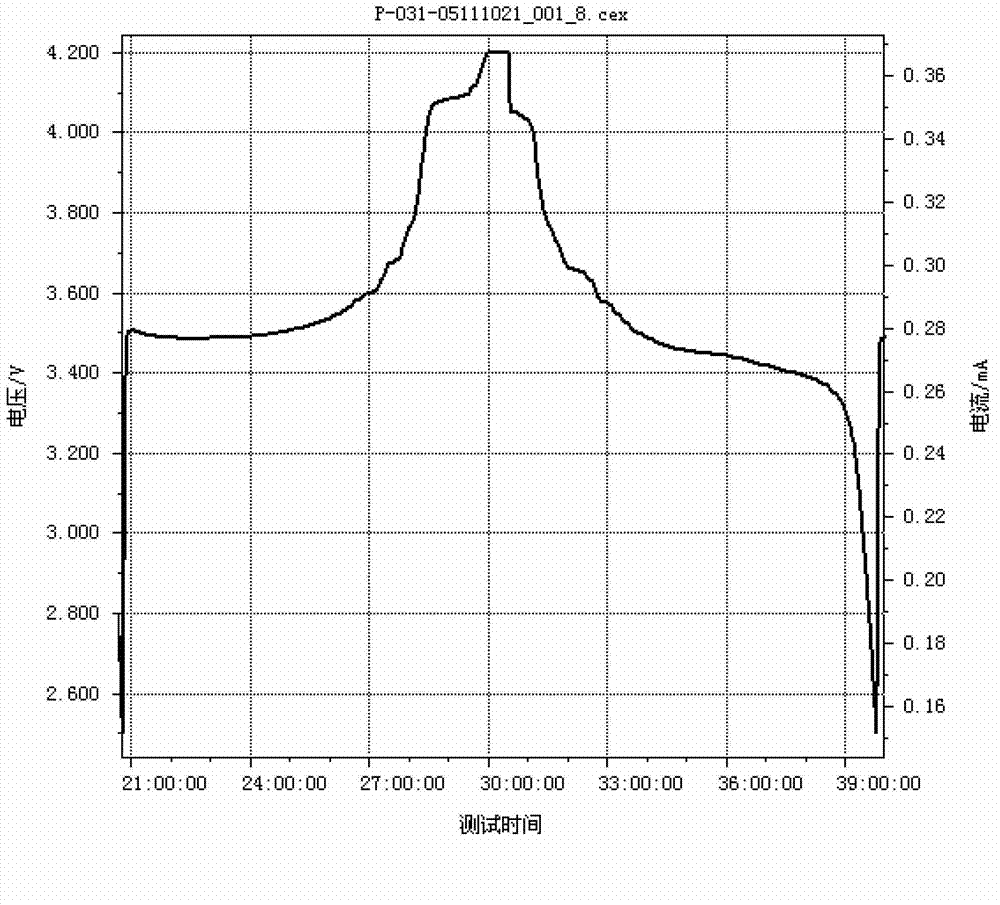

[0025] A lithium-ion battery cathode material consisting of carbon-coated lithium vanadium-iron-manganese phosphate, the chemical formula of which is LiV x Fe y mn 1-3 / 2x-y PO 4 , where x=0.3, y=0.5.

[0026] A method for preparing a positive electrode material for a lithium ion battery, the steps comprising:

[0027] In an electrolytic cell without a diaphragm, a pure iron plate is used as the anode, a stainless steel 1Cr18Ni9Ti plate is used as the cathode, and 1.0 mol / L phosphoric acid aqueous solution is used as the electrolyte. 2 Electrolyze the ferric ion phosphoric acid solution for 6 h with the electric current; add manganese acetate and vanadium pentoxide into the adjusted ferric ion phosphoric acid aqueous solution, heat to 40°C, stir and mix at a speed of 600 r / min for 2 h, then add hydrogen Lithium oxide, citric acid and glucose, continue stirring and reacting for 10 h to obtain rheological phase liquid, the molar ratio of lithium, vanadium, iron, manganese, p...

Embodiment 2

[0031] A lithium-ion battery cathode material consisting of carbon-coated lithium vanadium-iron-manganese phosphate, the chemical formula of which is LiV x Fe y mn 1-3 / 2x-y PO 4 , where x=0.2, y=0.5.

[0032] A method for preparing a positive electrode material for a lithium ion battery, the steps comprising:

[0033] In an electrolytic cell without a diaphragm, a pure iron rod is used as the anode, a stainless steel mesh is used as the cathode, 1.8 mol / L phosphoric acid aqueous solution is used as the electrolyte, the temperature of the electrolyte is 24°C, and a current of 4.5 A / dm2 is electrolyzed for 1.2 h to obtain ferric ions Phosphoric acid solution: Add manganese carbonate and vanadium pentoxide into the adjusted ferric ion phosphoric acid aqueous solution, heat to 50°C, stir and mix at a speed of 400r / min for 3h, then add lithium hydroxide, citric acid and glucose, and continue stirring After reacting for 10 hours, the rheological phase liquid was obtained, and the ...

Embodiment 3

[0037] A lithium-ion battery cathode material consisting of carbon-coated lithium vanadium-iron-manganese phosphate, the chemical formula of which is LiV x Fe y mn 1-3 / 2x-y PO 4 , where x=0.1, y=0.3.

[0038] A method for preparing a positive electrode material for a lithium ion battery, the steps comprising:

[0039] Add ferrous acetate, diammonium hydrogen phosphate, manganese acetate and ammonium metavanadate into pure water, heat to 60°C, stir and mix at a speed of 300r / min for 3 hours, then add lithium dihydrogen phosphate, citric acid and glucose, and continue stirring After reacting for 10 hours, the rheological phase liquid was obtained, and the molar ratio of lithium, vanadium, iron, manganese, phosphorus and carbon in the rheological phase liquid was 1.0: 0.1: 0.3: 0.55: 1.0: 0.08, and the mass ratio of citric acid and glucose was 1: 2;

[0040] Spray-dry the rheological phase liquid with a high-speed centrifugal spray dryer to obtain the precursor of vanadium-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com