Nitrogen-doped carbon/nano-silicon composite negative electrode material and preparation method thereof

A nitrogen-doped carbon, negative electrode material technology, applied in negative electrodes, nano-carbon, nanotechnology and other directions, can solve the problems affecting battery performance, poor conductivity of silicon-based materials, volume expansion, etc., to achieve electrochemical capacity improvement, high usage Efficiency, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An embodiment of the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in the present invention, the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in this embodiment includes the following steps:

[0034] (1) Put 0.2g of nano-silicon powder into 30mL of ethanol, add 20mL of 1mol / L sodium persulfate solution after ultrasonic dispersion and stir at 0°C for 0.5h to obtain dispersion A; The diameter is 30nm;

[0035] (2) Add 500 μL of pyrrole to the dispersion A obtained in step (1), stir and mix, and react at 0°C for 5 hours, filter and wash the obtained solid with ethanol and water, and dry at 60°C to obtain precursor B;

[0036] (3) Precursor B obtained in step (2) was calcined at 800° C. for 3 hours and then cooled to obtain the nitrogen-doped carbon and nano-silicon composite negative electrode material.

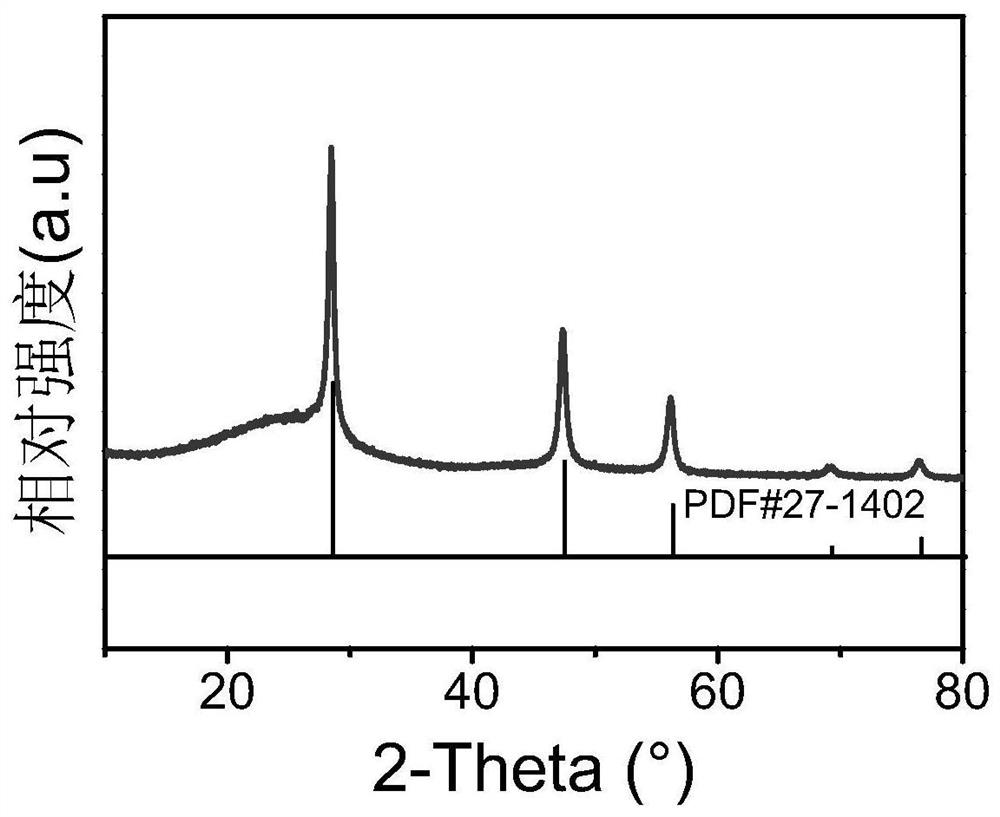

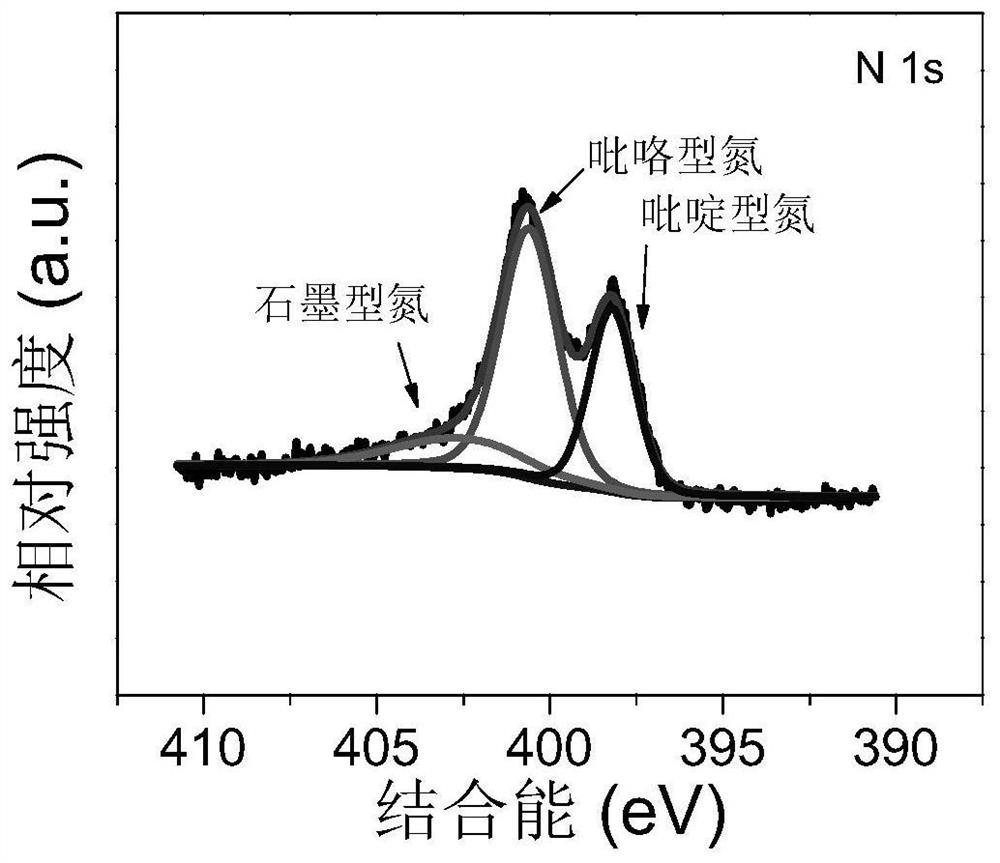

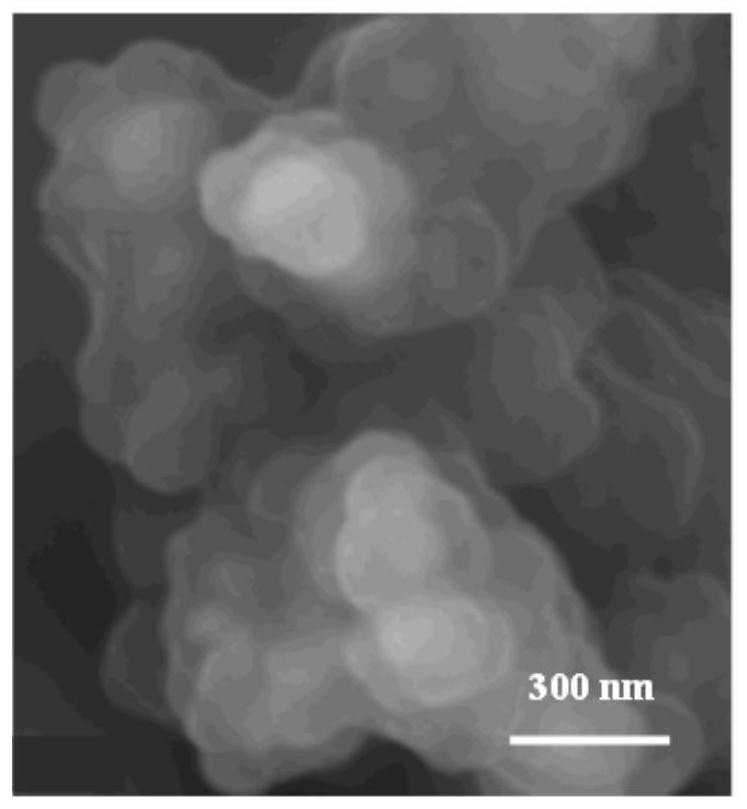

[0037] Carry out X-ray powder diff...

Embodiment 2

[0044] An embodiment of the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in the present invention, the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in this embodiment includes the following steps:

[0045] (1) Put 0.2g of nano-silica powder into 30mL of ethylene glycol, add 20mL of 1mol / L sodium persulfate solution after ultrasonic dispersion and stir at 0°C for 0.5h to obtain dispersion A; the nano-silica powder The particle size is 80nm;

[0046] (2) Add 500 μL of pyrrole to the dispersion A obtained in step (1), stir and mix, and react at 0°C for 5 hours, filter and wash the obtained solid with ethanol and water, and dry at 60°C to obtain precursor B;

[0047] (3) Precursor B obtained in step (2) was calcined at 800° C. for 3 hours and then cooled to obtain the nitrogen-doped carbon and nano-silicon composite negative electrode material.

...

Embodiment 3

[0050] An embodiment of the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in the present invention, the preparation method of the nitrogen-doped carbon and nano-silicon composite negative electrode material described in this embodiment includes the following steps:

[0051] (1) Put 0.2g of nano-silicon powder into 30mL of deionized water, add 20mL of 1mol / L ferric chloride solution after ultrasonic dispersion and stir at 0°C for 0.5h to obtain dispersion A; the nano-silicon powder The particle size is 30nm;

[0052] (2) Add 500 μL of aniline to the dispersion A obtained in step (1), stir and mix, and react at 0°C for 5 hours, filter and wash the obtained solid with ethanol and water, and dry at 60°C to obtain precursor B;

[0053] (3) Precursor B obtained in step (2) was calcined at 650° C. for 4 hours and then cooled to obtain the nitrogen-doped carbon and nano-silicon composite negative electrode material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com