High energy density safe lithium-ion battery

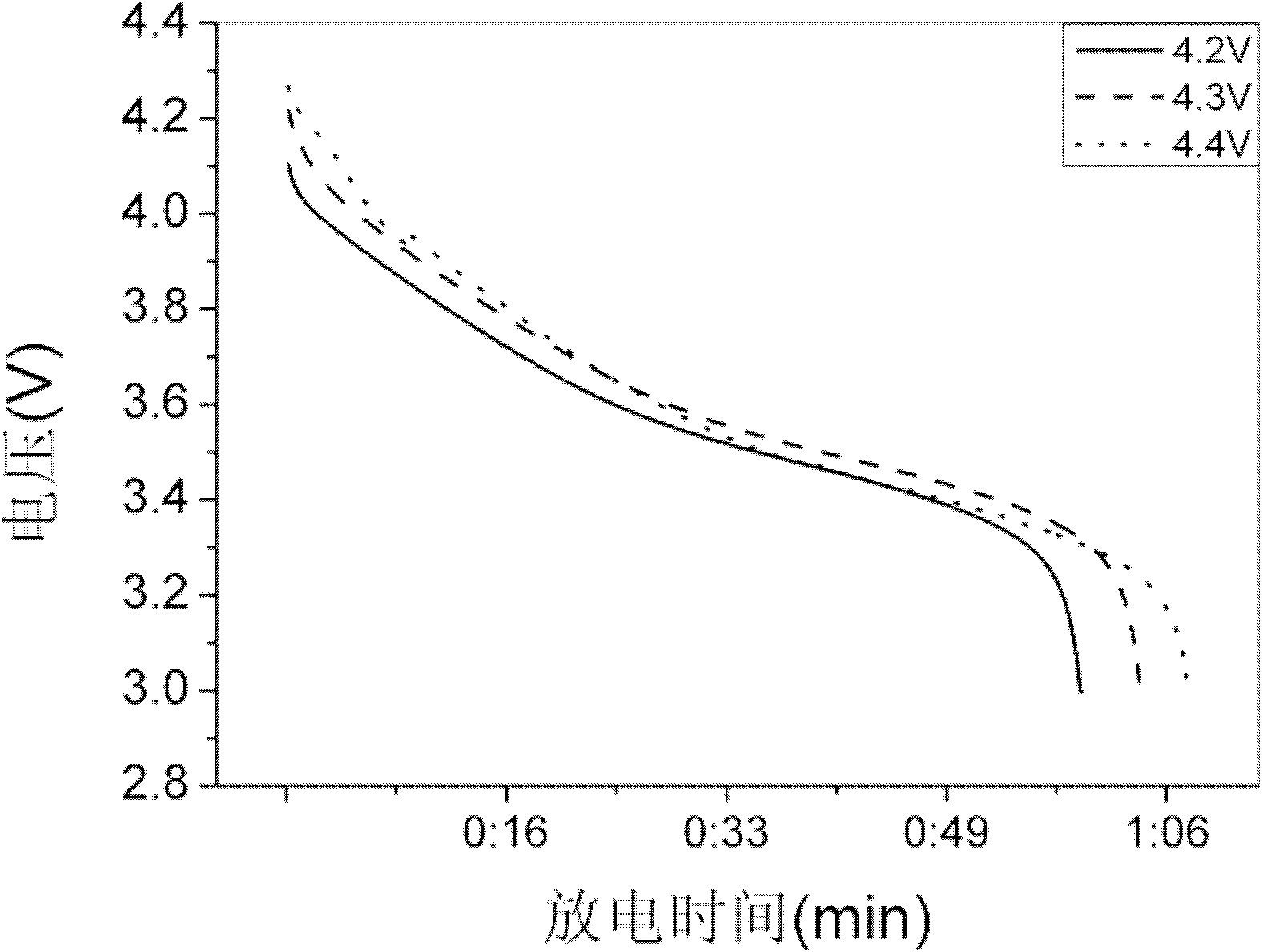

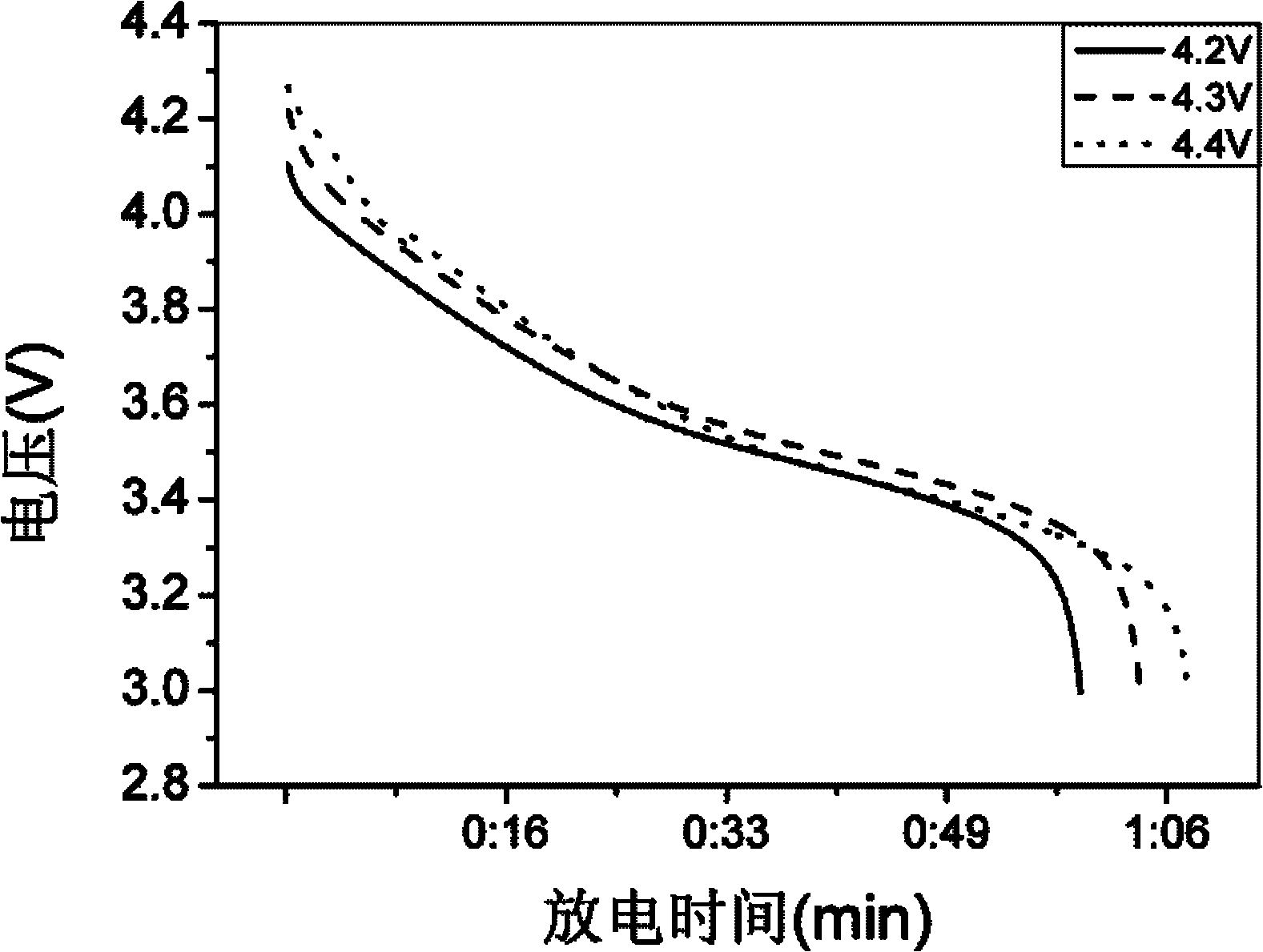

A high-energy density, lithium-ion battery technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve problems such as fire, small temperature range, short circuit of positive and negative electrodes, and achieve high electrochemical capacity, Improve safety performance and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The lithium-ion battery provided in this embodiment includes a positive electrode sheet, a negative electrode sheet, a separator, and an electrolyte. Among them, the active material of the positive electrode sheet is a ternary material of nickel, cobalt, and manganese, and an oxygen absorber is added to the positive electrode slurry; the surface of the positive electrode sheet is coated with a layer of ceramic material (PVDF composite film). The separator of the battery is a composite film of polyolefin separator and aromatic polyamide.

[0024] The slurry composition of the positive plate is active material: oxygen absorbing agent: carbon black: PVDF=92-96%: 0.1-3%: 1-3.5%: 2-3.5% (mass ratio). The molecular formula of the positive active material is LiNi x mn y co 1-x-y o 2 , 1≤x≤9, 9≥y≥1. The oxygen absorbing agent includes: 1. All organic substances containing active groups such as double bonds and carbonyl groups on the main chain or side chain; 2. All organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com