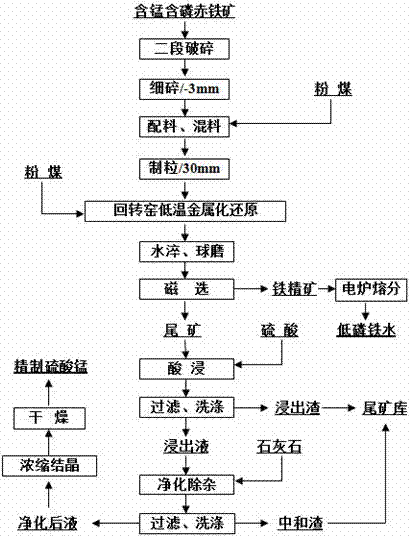

Method of processing manganese-containing and phosphorus-containing hematite

A processing method, hematite technology, applied in grain processing, chemical instruments and methods, solid separation, etc., can solve problems that have not been researched, and achieve good separation effect, good enrichment effect, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Manganese-containing phosphorus-containing hematite raw ore (Fe 40%, MnO 5%, P 2 o 5 1%, Al 2 o 3 5%, SiO 2 20%) broken to less than 3mm accounted for 88%, mixed with 22% bituminous coal, mixed and granulated (particle size 30mm), the pellets were roasted at a constant temperature of 1000°C in the rotary kiln for 2 hours, and the flue gas CO / CO 2 4; the calcine is cooled slowly to 500°C with water quenching and rapid cooling, water quenching calcine ball milling, and the grinding particle size is less than 0.074mm, accounting for 87%; the mass concentration of the pulp is controlled at 20%, and the magnetic field strength is 1000 Oersted magnetic separation to obtain sponge-like iron powder (Fe 90%, P 0.1%, Al 2 o 3 1.5%, SiO 2 3.2%) and manganese-rich tailings (Mn 8%, Fe 6%); sponge-like iron powder was melted at 1550°C for 2 hours to obtain high-quality molten iron (P 0.005%, Mn 0.3%); manganese-rich tailings were diluted with 1mol / L Sulfuric acid leaching...

Embodiment 2

[0041] Manganese-containing phosphorus-containing hematite raw ore (Fe 35%, MnO 10%, P 2 o 5 1%, Al 2 o 3 9%, SiO 2 20%) broken to less than 3mm accounted for 90%, mixed with 20% bituminous coal, mixed and granulated (particle size 25mm), the pellets were roasted at 980°C for 3 hours in a rotary kiln, and the flue gas CO / CO 2 It is 3.9; the calcined sand is cooled slowly to 550°C with water quenching and rapid cooling, and the water quenching calcined sand is ball milled, and the grinding particle size is less than 0.074mm, accounting for 93%; the mass concentration of the pulp is controlled at 20%, and the magnetic field strength is 1000 Oersted magnetic separation to obtain sponge-like iron powder (Fe 91%, P 0.08%, Al 2 o 3 1.6%, SiO 2 3.3%) and manganese-rich tailings (Mn 9%, Fe 7%); sponge-like iron powder was melted at 1580°C for 1.5h to obtain high-quality molten iron (P 0.005%, Mn 0.2%); manganese-rich tailings used 1.2mol / L dilute sulfuric acid leaching, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com