Transparent organic silicon resin for room temperature resin transfer moulding and preparation method of transparent organic silicon resin

A technology of resin transfer molding and silicone, applied in the field of transparent silicone resin for room temperature resin transfer molding and its preparation, to achieve excellent dielectric properties and thermal stability, wide source of raw materials, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Synthesis of polymethylphenyl vinyl siloxane

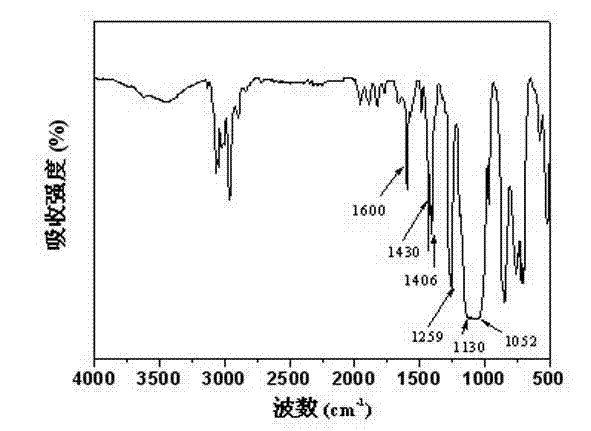

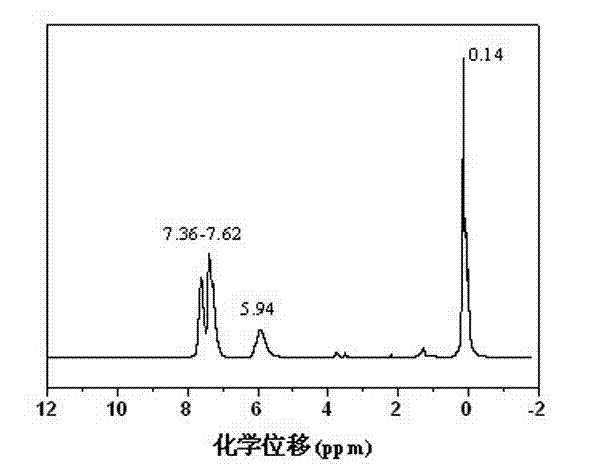

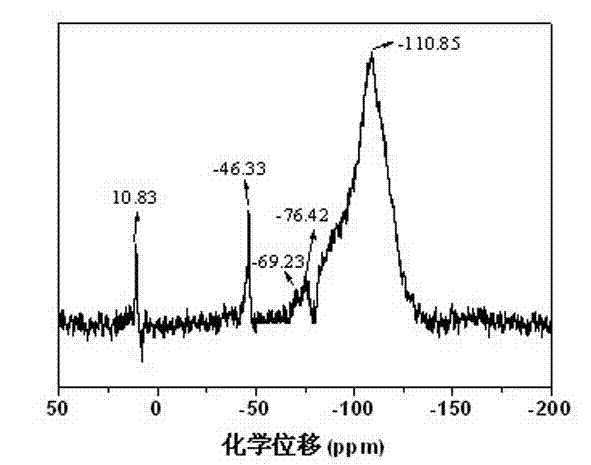

[0035] Under nitrogen atmosphere, after mixing 12.30 g methyltrimethoxysilane, 10.98 g diphenyldimethoxysilane and 43.90 g vinyltrimethoxysilane evenly, add it dropwise to 60 mL at a rate of 20 drops / min In a solvent mixed with ethanol and 15.90 g of deionized water, the pH was adjusted to 3 with hydrochloric acid, and the reaction was controlled at a temperature of 40° C. for 3 hours. Then 30.00 g of hexamethyldisiloxane and 3.33 g of deionized water were added to react at 40° C. for 1.5 hours, and then heated to 70° C. for 6 hours. Cooling, standing for stratification, and obtaining the oily substance in the lower layer, drying in vacuum, it is polymethylphenyl vinyl siloxane, its molecular weight is 4930, and Si-CH=CH is measured by iodometric method. 2 The content is 2.34×10 -3 mol / g, viscosity at 20°C is 2017 mPa.s. Its infrared spectrogram, proton nuclear magnetic resonance spectrum and silicon nuclear magn...

Embodiment 2

[0054] 1. Synthesis of polymethylphenyl vinyl siloxane

[0055] Under nitrogen atmosphere, after mixing 10.30 g methyltrimethoxysilane, 4.12 g diphenyldimethoxysilane and 10.30 g vinyltrimethoxysilane, dropwise added to 80 mL In a solvent mixed with ethanol and 5.15 g of deionized water, the pH was adjusted to 3.5 with hydrochloric acid, and the reaction was controlled at a temperature of 45° C. for 2.5 hours. Then 13.91 g of hexamethyldisiloxane and 2.58 g of deionized water were added to react at 45° C. for 1.5 hours, and then heated to 80° C. for 6 hours. Cooling, standing to separate layers, get the oily substance in the lower layer, dry it in vacuum, it is polymethylphenyl vinyl siloxane, its molecular weight is 5029, Si-CH=CH 2 The content is 2.26×10 -3 mol / g, the viscosity at 20°C is 2136 mPa.s.

[0056] 2. Synthesis of hyperbranched polysiloxane containing silicon hydrogen bond and silicon methyl group

[0057] Under a nitrogen atmosphere, after mixing 14....

Embodiment 3

[0061] 1. Synthesis of polymethylphenyl vinyl siloxane

[0062] Under nitrogen atmosphere, after mixing 13.40 g methyltrimethoxysilane, 8.04 g diphenyldimethoxysilane and 12.06 g vinyltrimethoxysilane evenly, add dropwise to 70 mL at a rate of 15 drops / min In a solvent mixed with ethanol and 6.80 g of deionized water, the pH was adjusted to 2.5 with hydrochloric acid, and the reaction was controlled at a temperature of 30° C. for 3 hours. Then 17.42 g of hexamethyldisiloxane and 2.68 g of deionized water were added to react at 30° C. for 2 hours, and then heated to 70° C. for 6 hours. Cooling, standing to separate layers, get the lower layer of oil, vacuum drying, that is, polymethylphenyl vinyl siloxane, its molecular weight is 5324, Si-CH=CH 2 The content is 2.35×10 -3 mol / g, viscosity at 20°C is 2260 mPa.s.

[0063] 2. Synthesis of hyperbranched polysiloxane containing silicon hydrogen bond and silicon methyl group

[0064]Under a nitrogen atmosphere, after mixing 16.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com