Preparation method and application of tantalum-based hierarchical structure hollow nanometer photocatalytic material

A technology of photocatalytic materials and hierarchical structures, applied in chemical instruments and methods, oxygen preparation, physical/chemical process catalysts, etc., to achieve high quantum efficiency of oxygen production, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

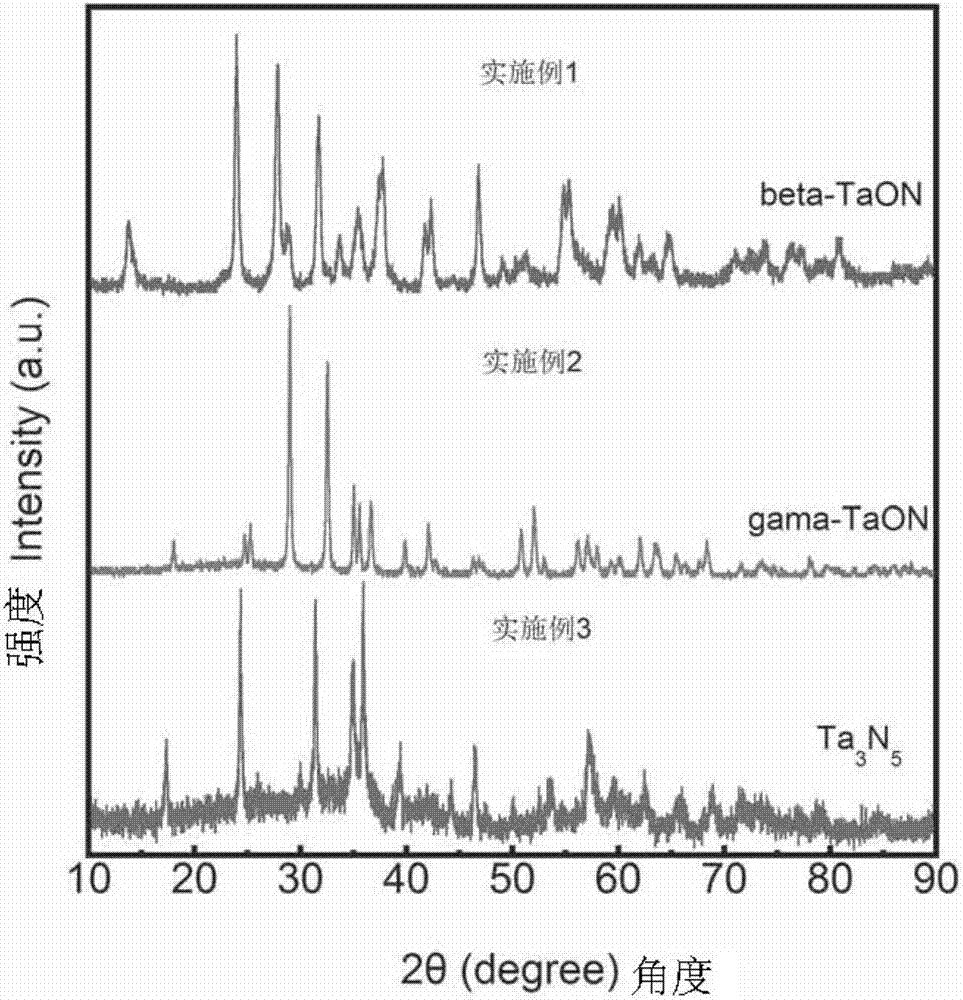

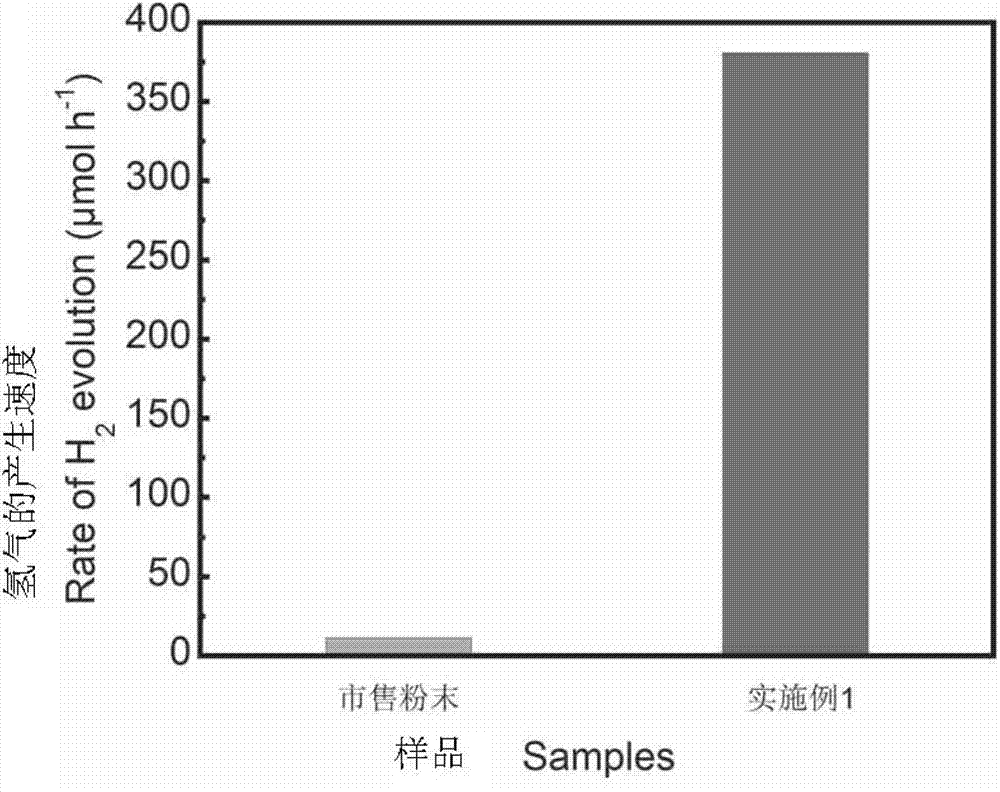

Embodiment 1

[0022] Add 0.5g of tantalum powder to 0.6mol / L hydrofluoric acid and 50mL of 2mol / L hydrogen peroxide solution.

[0023] Pour the mixed suspension into a 100mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 220°C, and react for 6 hours. After the reaction, cool in the furnace.

[0024] The reactant was centrifuged to obtain a solid powder, which was washed several times with distilled water and alcohol and then dried at 60°C. Put it into a muffle furnace for sintering at 800°C for 5h. Control the flow rate of ammonia gas in the atmosphere to 20mL / min, and control the temperature of the water bottle to 20°C. Cool down with the furnace after the reaction. Product analysis using X-ray Diffraction (XRD), Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)

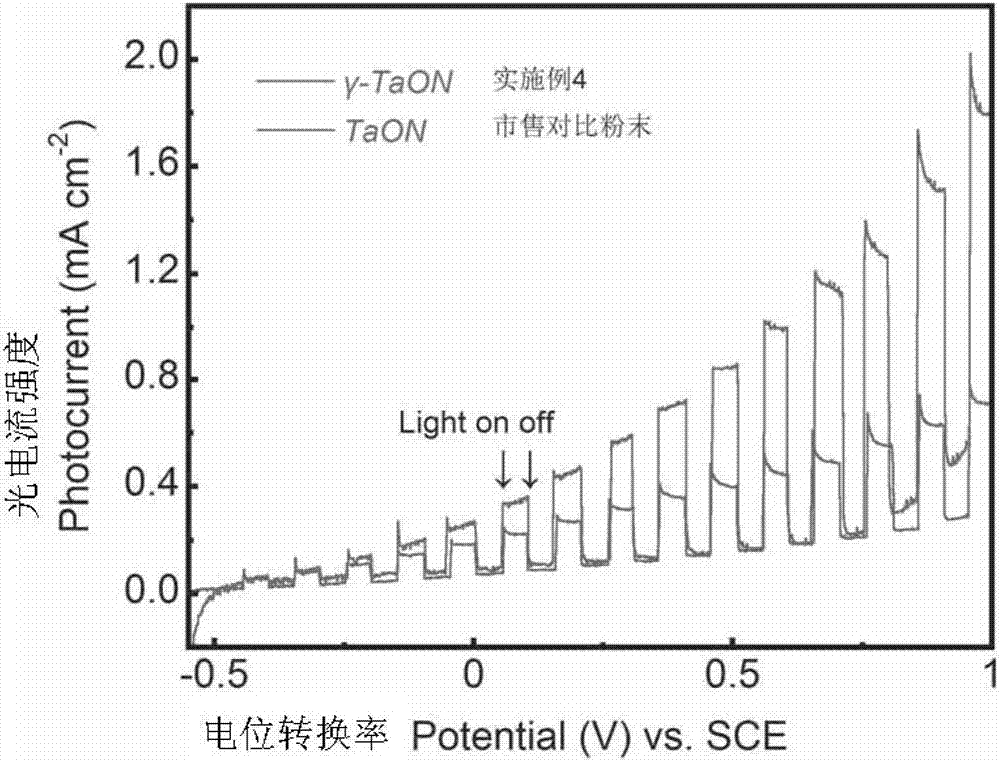

Embodiment 2

[0026] Add 0.5g of tantalum powder to 0.1 mol / L hydrofluoric acid and 50mL of 3mol / L hydrogen peroxide solution.

[0027] Pour the mixed suspension into a 100mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 300°C, and react for 24 hours. After the reaction, cool with the furnace.

[0028] The reactant was centrifuged to obtain a solid powder, which was washed several times with distilled water and alcohol and then dried at 60°C. Put it into a muffle furnace and sinter at 700°C for 10h. The flow rate of ammonia gas in the atmosphere was controlled to 20mL / min, and the temperature of the water bottle was controlled to 35°C. Cool down with the furnace after the reaction.

Embodiment 3

[0030] Add 1g of tantalum powder to 0.6mol / L hydrofluoric acid and 50mL of 3mol / L hydrogen peroxide solution.

[0031] Pour the mixed suspension into a 100mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 160°C, and react for 1 hour. After the reaction, cool in the furnace.

[0032] The reactant was centrifuged to obtain a solid powder, which was washed several times with distilled water and alcohol and then dried at 60°C. Put it into a muffle furnace and sinter at 900°C for 20h. Control the flow of ammonia gas in the atmosphere to 60mL / min, and control the temperature of the water bottle to 20°C. Cool down with the furnace after the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com