Preparation method and application of particle uniformly-coated heterojunction type photo-catalytic material

A technology with uniform particles and heterojunctions, which is applied in chemical instruments and methods, oxygen preparation, physical/chemical process catalysts, etc., can solve the problems of limited applications and restrictions, and achieve good catalytic water splitting activity and high oxygen production quantum The effect of efficiency, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

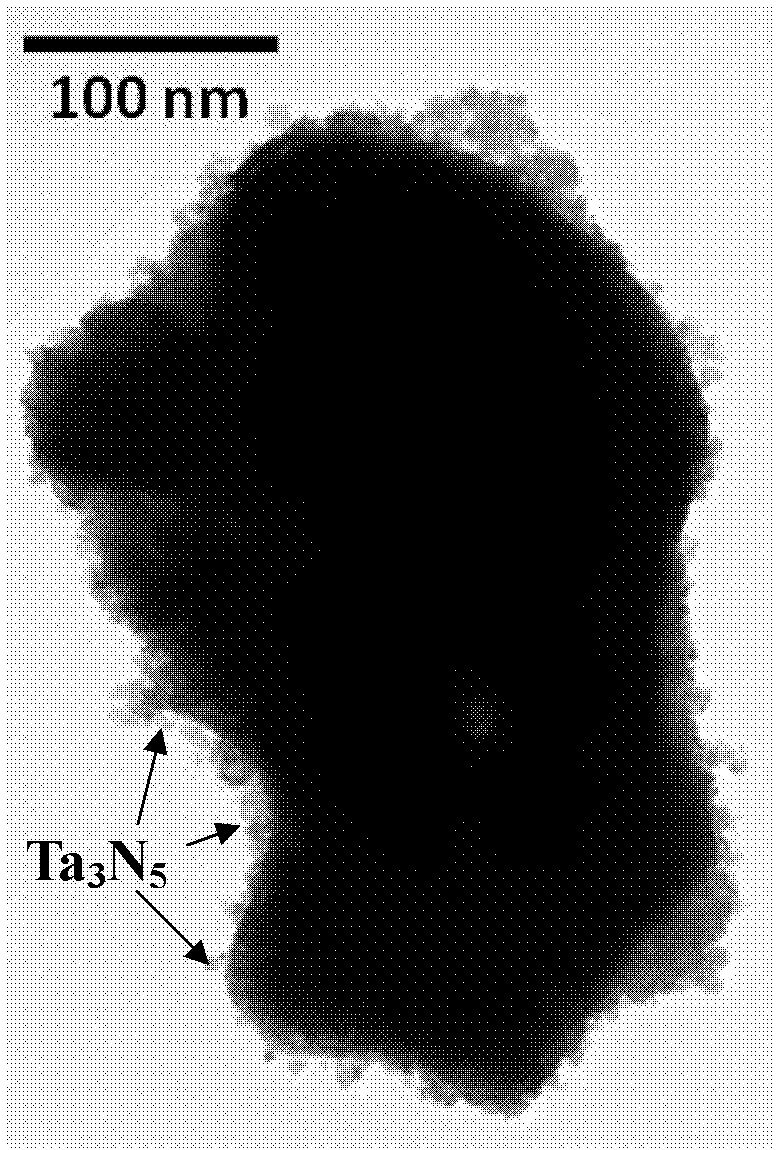

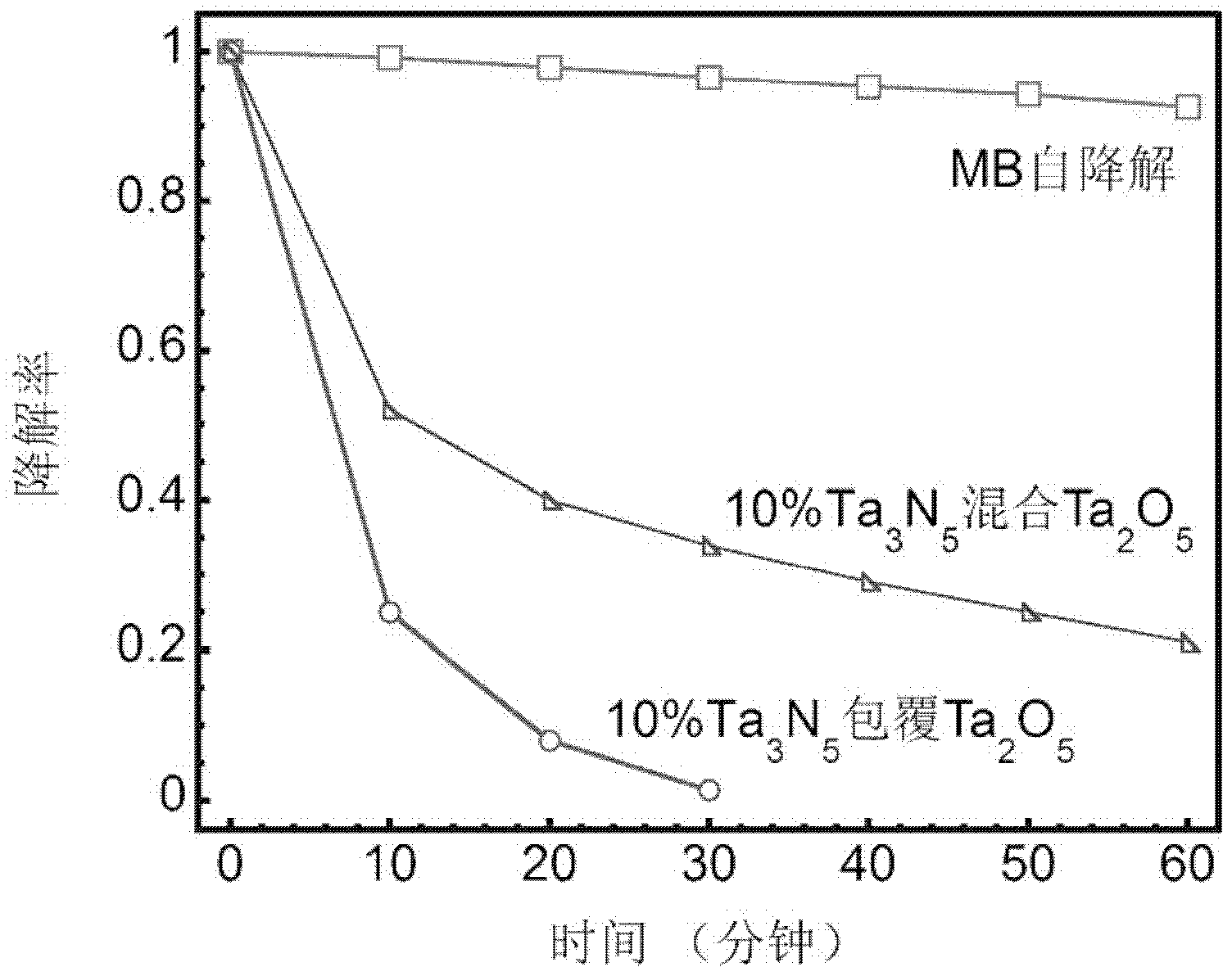

[0022] Take Ta 3 N 5 : Ta = 50% as an example. First, add 0.5g tantalum chloride into 140mL carbon tetrachloride solvent, add 0.5mg Ta powder into the prepared solution, and then add it into the liquid ammonia solution of K for reaction, TaCl 5The molar ratio to K is 1:5, the reaction time is 90 minutes, and then heat treatment is carried out in an ammonia atmosphere furnace at a temperature of 900 °C for 2 hours to obtain a heterojunction photocatalyst.

Embodiment 2

[0024] Take Ta 3 N 5 : Ta = 10% as an example. First, add 0.5g tantalum bromide to 2mL ethyl bromide solvent, add 5mg Ta powder to the prepared solution, and then add it to the liquid ammonia solution of Na for reaction, TaBr 5 The molar ratio to Na is 1:5.5, the reaction time is 60 minutes, and then heat treatment is carried out in an argon atmosphere furnace at a temperature of 800 °C for 4 hours to obtain a heterojunction photocatalyst.

Embodiment 3

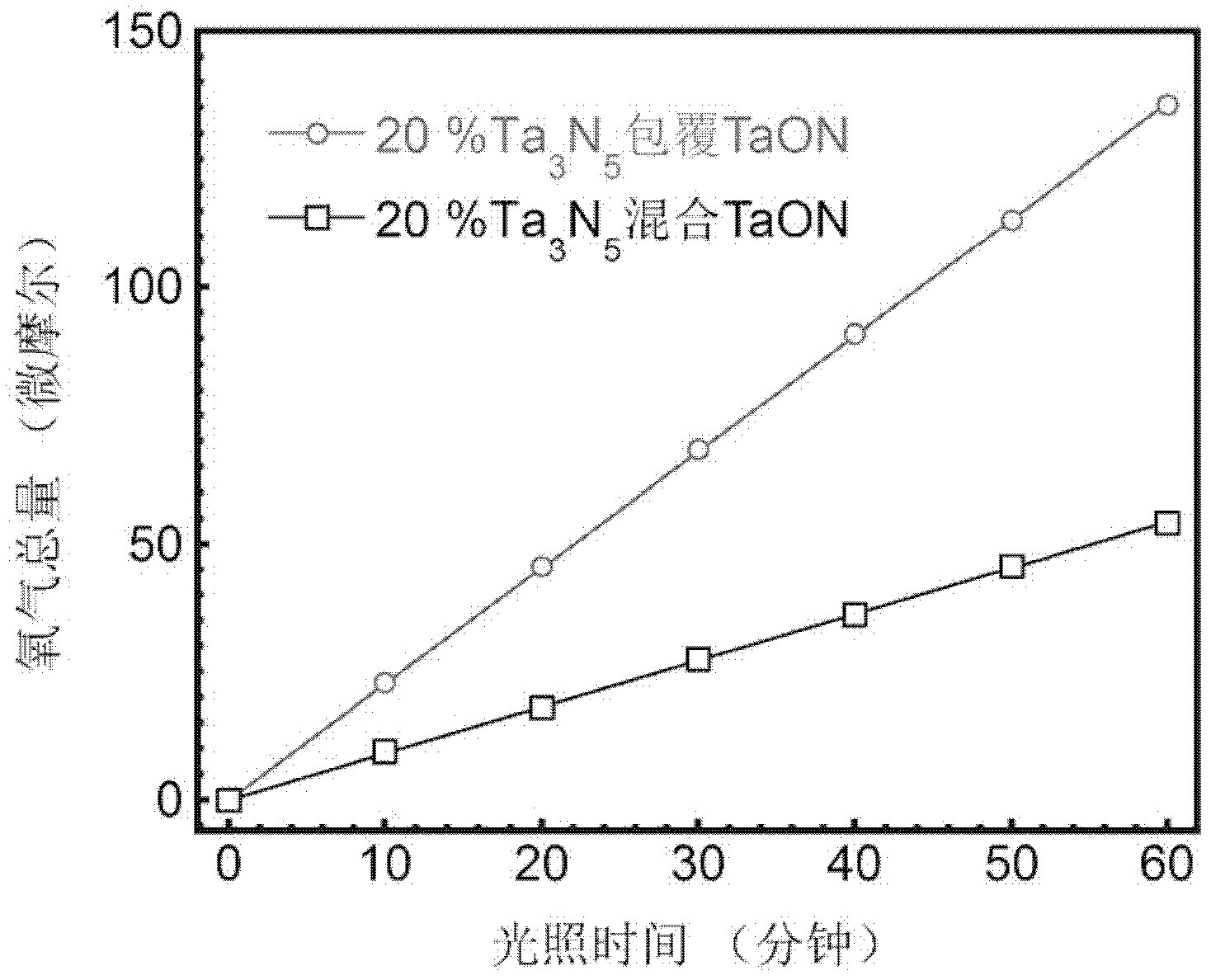

[0026] Take Ta 3 N 5 : TaON = 20% as an example. First, add 0.5g tantalum bromide to 100mL carbon tetrachloride solvent, add 0.1g TaON powder to the prepared solution, and then add it to the liquid ammonia solution of Na for reaction, TaBr 5 The molar ratio to Na was 1:5, the reaction time was 60 minutes, and then heat treatment was carried out in an argon atmosphere furnace at a temperature of 700°C for 6 hours to obtain a heterojunction photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com