Preparation method of low-dimensional tantalum-based nano-array photo-electrode

A nano-array, photoelectrode technology, applied in electrodes, electrical components, electrolysis process, etc., to achieve the effect of high oxygen production quantum efficiency, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 1cm×2cm tantalum foil to 0.05mol / L hydrofluoric acid, 2mol / L hydrogen peroxide and 8.0x10 -3 mol / L copper acetate mixed solution 16mL.

[0022] (2) Put the mixed solution and tantalum foil into a 30mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 200°C, react for 12 hours, and cool in the furnace after the reaction.

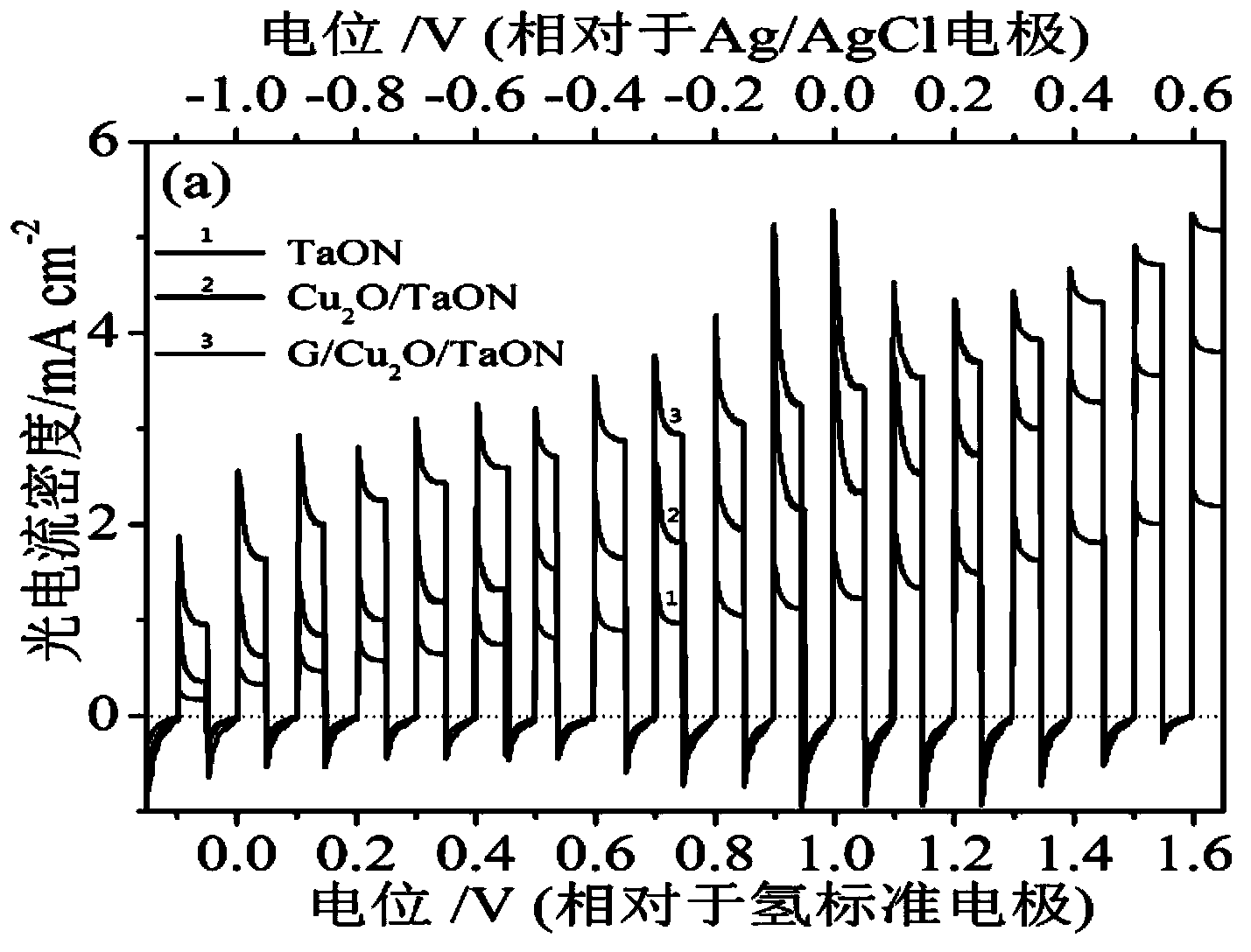

[0023] (3) The reaction product was washed several times with distilled water and alcohol and then dried at 60°C. XRD diffraction of the phase structure of the tantalum oxide photoelectrode is as follows: figure 1 shown. Put it into a muffle furnace and sinter at 700°C for 5h. The flow rate of ammonia gas in the atmosphere was controlled to 20mL / min, and the temperature of the water bottle was controlled to 30°C. After the reaction is completed, cool down with the furnace to obtain Cu 2 O / TaON photoelectrodes. The product was analyzed by X-ray diffraction (XRD) and scanning electron microscope (SEM).

[0024] (4) The pro...

Embodiment 2

[0027] (1) Add 1cm×2cm tantalum foil to 16mL of a mixed solution of 0.08mol / L hydrofluoric acid and 4mol / L hydrogen peroxide.

[0028] (2) Put the mixed solution and tantalum foil into a 30mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 240°C, react for 6 hours, and cool in the furnace after the reaction.

[0029] (3) The reaction product was washed several times with distilled water and alcohol, and then dried at 60°C. Put it into a muffle furnace and sinter at 700°C for 1h, 2h and 60h. The flow rate of ammonia gas in the atmosphere was controlled to 20mL / min, and the temperature of the water bottle was controlled to 30°C. After the reaction is completed, cool with the furnace to obtain γ-TaON array electrodes, β-TaON array electrodes, Ta 3 N 5 Array electrodes, XRD diffraction such as figure 1 .

Embodiment 3

[0031] (1) Add 1cm×2cm tantalum foil to 0.25mol / L hydrofluoric acid, 6mol / L hydrogen peroxide and 5.0x10 -3 mol / L copper acetate mixed solution 16mL.

[0032] (2) Put the mixed solution and tantalum foil into a 30mL polytetrafluoroethylene-lined stainless steel autoclave, heat up to 240°C, react for 6 hours, and cool in the furnace after the reaction.

[0033] (3) The reaction product was washed several times with distilled water and alcohol, and then dried at 60°C. Put it into a muffle furnace and sinter at 720°C for 2h. The flow rate of ammonia gas in the atmosphere was controlled to 10mL / min, and the temperature of the water bottle was controlled to 30°C. After the reaction is completed, it is obtained by cooling the furnace to obtain Co 3 o 4 / Co(II)Ta 3 N 5 photoelectrode.

[0034] (4) Subsequent photoelectric conversion performance test, such as Figure 3b shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com