Method for treating poly butylene succinate production waste water by biochemical method

A technology for polybutylene succinate and waste water production, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Complex, difficult automatic control and other problems, to achieve the effect of convenient and reliable operation and management, reduced engineering investment, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

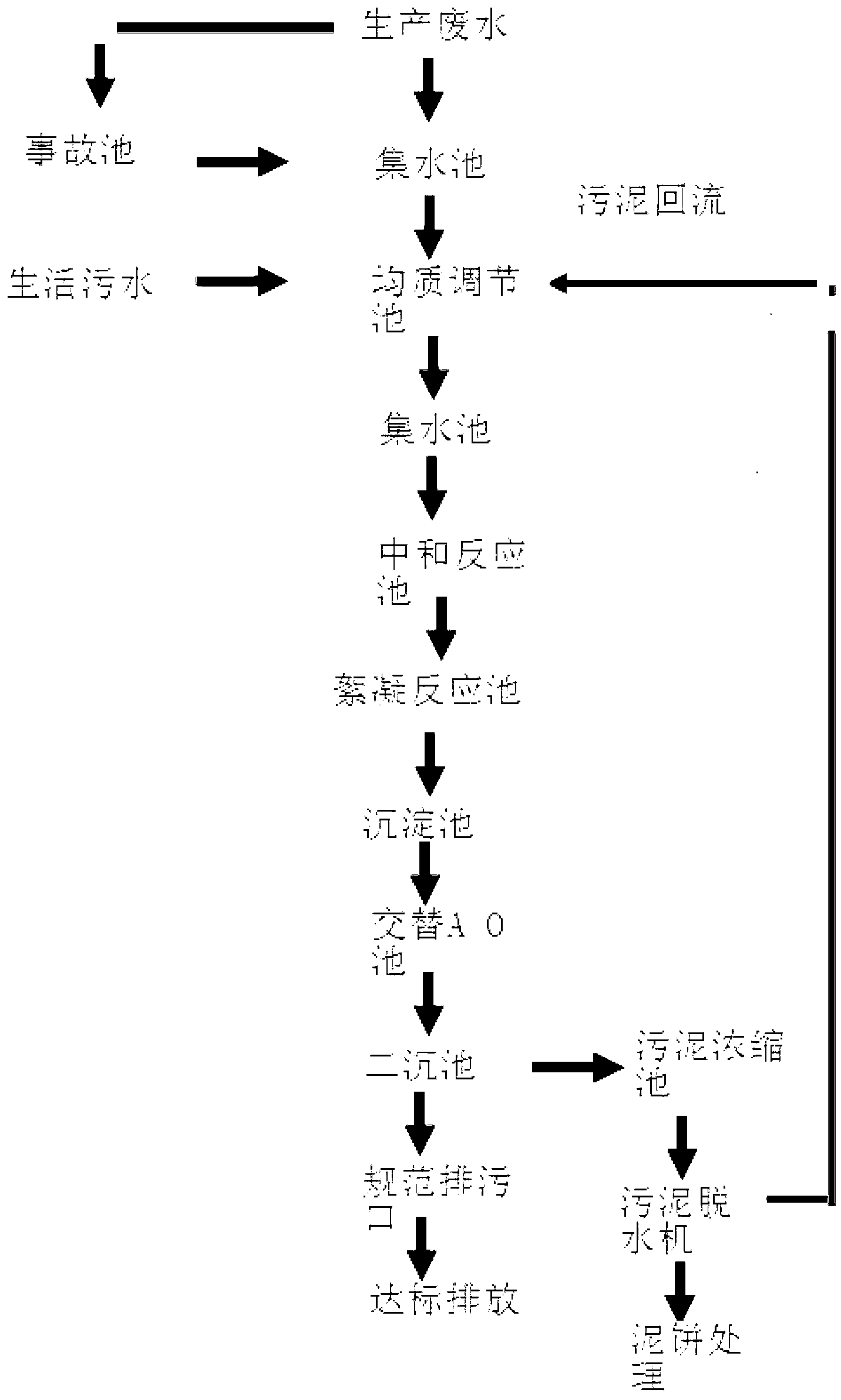

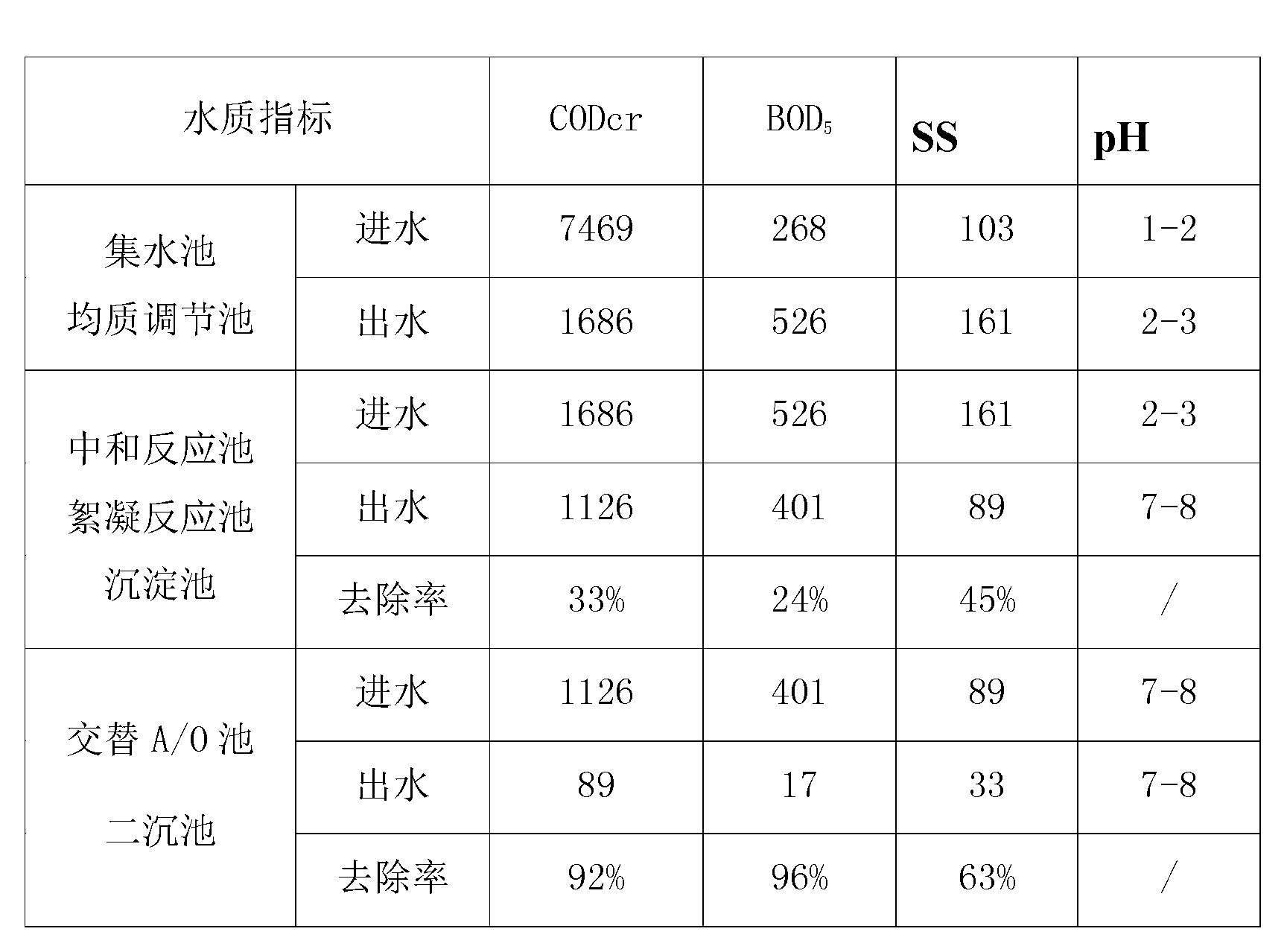

[0038] A method for biochemically treating polybutylene succinate production wastewater, comprising the following steps:

[0039](1) First buffer the production wastewater from the polybutylene succinate production workshop in the sump;

[0040] (2) Evenly convey to the homogeneous adjustment tank of the sewage treatment station, where it is mixed with the domestic sewage in the factory area;

[0041] (3) Elevate the pump to the neutralization reaction tank, add milk of lime under stirring conditions, so that the pH of the wastewater is between 6-9;

[0042] (4) Self-flow into the flocculation reaction tank, by continuously adding PAC flocculant polyaluminum chloride, the fine suspended solids and colloidal substances in the wastewater are aggregated into alum flowers with larger particle sizes;

[0043] (5) Sedimentation and separation in the sedimentation tank, the supernatant of the sedimentation tank flows into the A / O biochemical tank for reaction;

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com