Gluing composite connection joint and gluing composite connection method for FRP (fiber reinforced polymer) section and barbed plates

A composite connection and barbed plate technology, applied in the processing of building materials, bridge parts, erection/assembly of bridges, etc., can solve the problems of low joint efficiency, large lap length, shear failure of profiles, etc., to improve the shear strength. , The effect of high joint efficiency and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

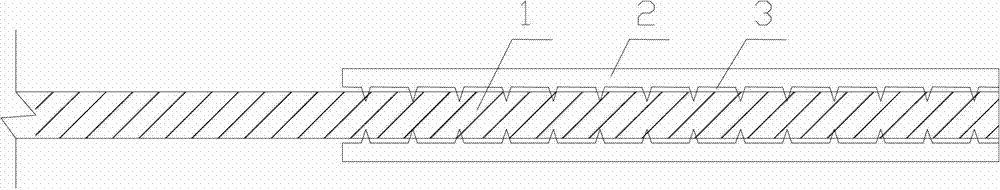

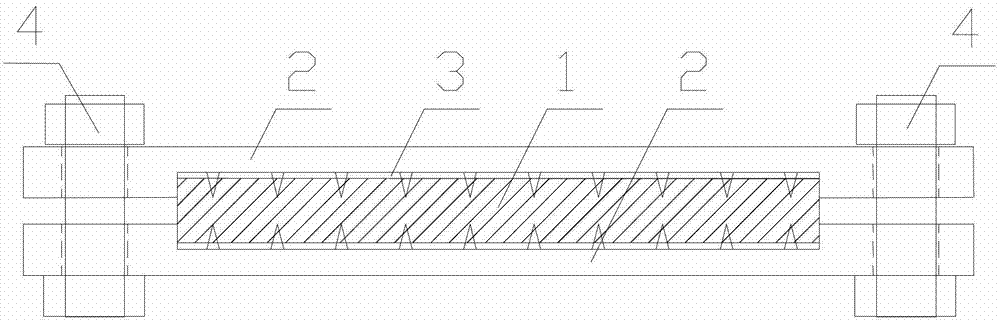

[0040] see figure 1 , figure 2 , image 3 , Figure 6 and Figure 7 Shown:

[0041]First, use a grinder to grind off the non-slip coating on the joint connection area of the FRP profile 1. When grinding, care should be taken to control the grinding depth, preferably 0.5mm±0.1mm.

[0042] Secondly, calibrate the size of the joint on the FRP profile 1, and apply the epoxy resin impregnating glue 3 on the joint of the FRP profile 1, preferably with a thickness of 0.5mm±0.1mm.

[0043] Thirdly, place one stabbing plate 2 on the plate surface of the static platform of the press, place the joint of the FRP profile 1 on the stabbing plate 2 and straighten it, place the other stabbing plate 2 on the FRP profile 1, and place the barbed plates of the two stabbing plates 2 The faces are all facing the FRP profile 1.

[0044] Fourth, start the press to pressurize, press the thorns of the thorn plate 2 into the FRP profile 1, and press the thorns into a certain depth: the thorn p...

Embodiment 2

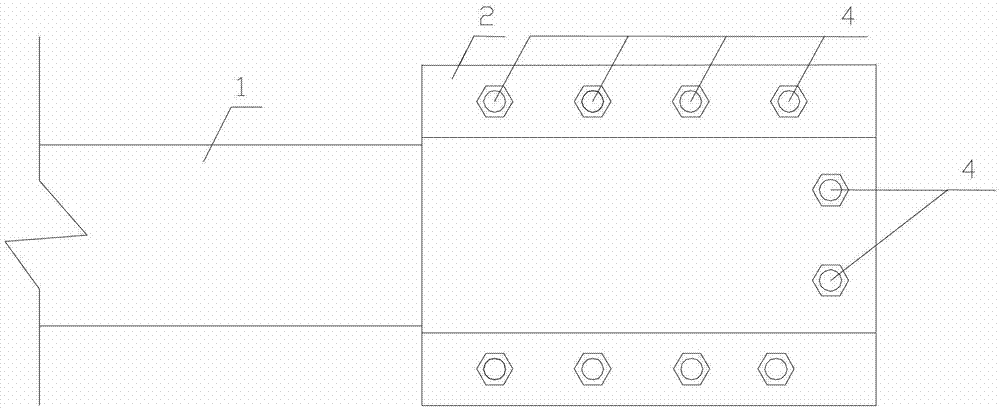

[0046] see figure 1 , Figure 4 and Figure 5 Shown:

[0047] Except for the following differences from Example 1, other parts are the same: there is no bolt hole for the upper and lower butt joints on the side of the spine plate 2, and there is no bolt hole at the end of the spine plate 2. The mounting bolt holes of the spine plate 2 are in the spine plate 2, so in When connecting with the FRP profile 1, bolt holes need to be opened at the corresponding positions of the FRP profile 1.

[0048] Compared with prior art methods, the beneficial effects of the present invention are:

[0049] 1. The connection between the thorn board and the FRP profile successfully introduces thorns into the shear interface of the glue layer, which greatly improves the shear strength of the glue layer interface, realizes the joint force of the cementation and the connection of the thorn board, and has high strength and good ductility , high joint efficiency and other advantages; please refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com