Solar-powered back plate and manufacturing method thereof

A technology of solar backsheet and polyethylene resin, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of poor interlayer peeling strength, low temperature resistance level, low mechanical strength, etc., and achieve enhanced The effect of interlayer peeling force, improved temperature resistance level, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

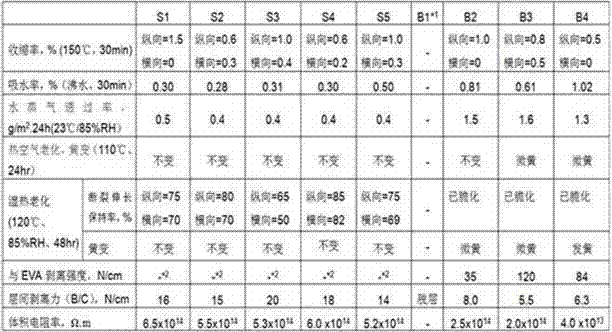

Examples

Embodiment 1

[0046] A solar backplane, the preparation method is as follows:

[0047] (1) Preparation of cross-linked polyethylene resin XPE

[0048] 100 parts (parts by mass) of metallocene polyethylene 1327ED (Exxon Chemical Company, USA), 2 parts of vinyl trimethoxysilane A151 (Dow Corning Company, USA), and 0.2 parts of DCP initiator (Tianjin Aksu Company) were respectively measured and added Mix and homogenize in the mixer. After homogenizing for two hours, put it into a twin-screw extruder for melt extrusion (the twin screw adopts an exhaust screw, the screw diameter is 75 mm, the length to diameter ratio is 33, and the screw temperature is controlled at 160~220 ℃, the screw speed is controlled to 100 rpm, the residence time of the material in the screw is 2~4 minutes); the cross-linked polyethylene XPE is obtained by cooling and pelletizing, and its melt flow rate at 190℃ / 2.16 kg is 0.2 gg / 10min.

[0049] The metallocene polyethylene 1327ED, density 0.927g / cm 3 , DSC melting point 122℃,...

Embodiment 2

[0058] A solar backplane, the preparation method is as follows:

[0059] (1) Preparation of cross-linked polyethylene resin XPE

[0060] 100 parts (parts by mass) of metallocene polyethylene 1327ED (Exxon Chemical Company, USA), 2 parts of vinyl trimethoxysilane A151 (Dow Corning Company, USA), and 0.16 parts of DCP initiator (Tianjin Aksu Company) were respectively measured and added Mix and homogenize in the mixer. After homogenizing for two hours, put it into a twin-screw extruder for melt extrusion (the twin screw adopts an exhaust screw, the screw diameter is 75 mm, the length to diameter ratio is 33, and the screw temperature is controlled at 160~220 ℃, the screw speed is controlled to 100 rpm, the residence time of the material in the screw is 2~4 minutes); the cross-linked polyethylene XPE is obtained by cooling and pelletizing, and its melt flow rate at 190℃ / 2.16 kg is 0.2 gg / 10min.

[0061] (2) Preparation of grafted polyethylene PE-MA

[0062] 100 parts (parts by mass) ...

Embodiment 3

[0068] A solar backplane, the preparation method is as follows:

[0069] (1) Preparation of cross-linked polyethylene resin XPE

[0070] 100 parts (parts by mass) of metallocene polyethylene 1327ED (Exxon Chemical Company, USA), 2 parts of vinyl trimethoxysilane A151 (Dow Corning Company, USA), and 0.2 parts of DCP initiator (Tianjin Aksu Company) were respectively measured and added Mix and homogenize in the mixer. After homogenizing for two hours, put it into a twin-screw extruder for melt extrusion (the twin screw adopts an exhaust screw, the screw diameter is 75 mm, the length to diameter ratio is 33, and the screw temperature is controlled at 160~220 ℃, the screw speed is controlled to 100 rpm, the residence time of the material in the screw is 2~4 minutes); the cross-linked polyethylene XPE is obtained by cooling and pelletizing, and its melt flow rate at 190℃ / 2.16 kg is 0.2 gg / 10min.

[0071] (2) Preparation of grafted polyethylene PE-MA

[0072] 100 parts (parts by mass) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com