Catalyst carrier, and preparation method and application thereof

A catalyst carrier and unit pore technology, applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems affecting mass transfer and heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

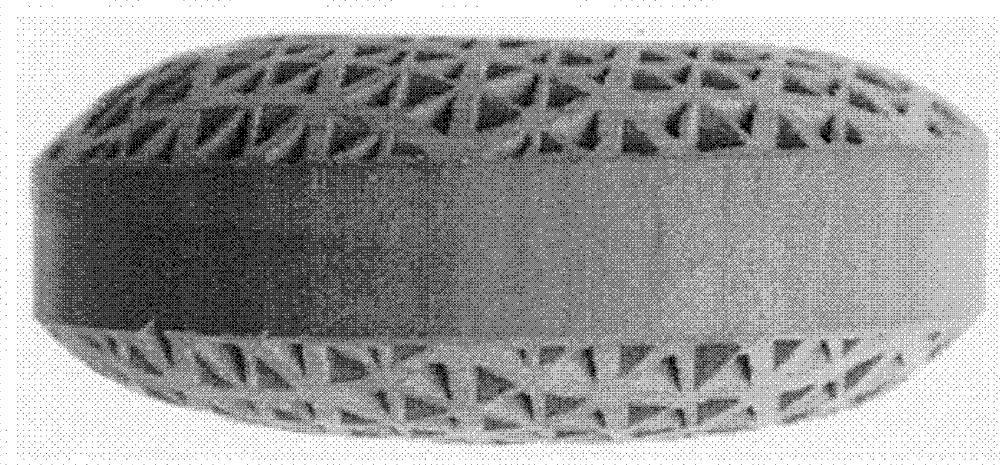

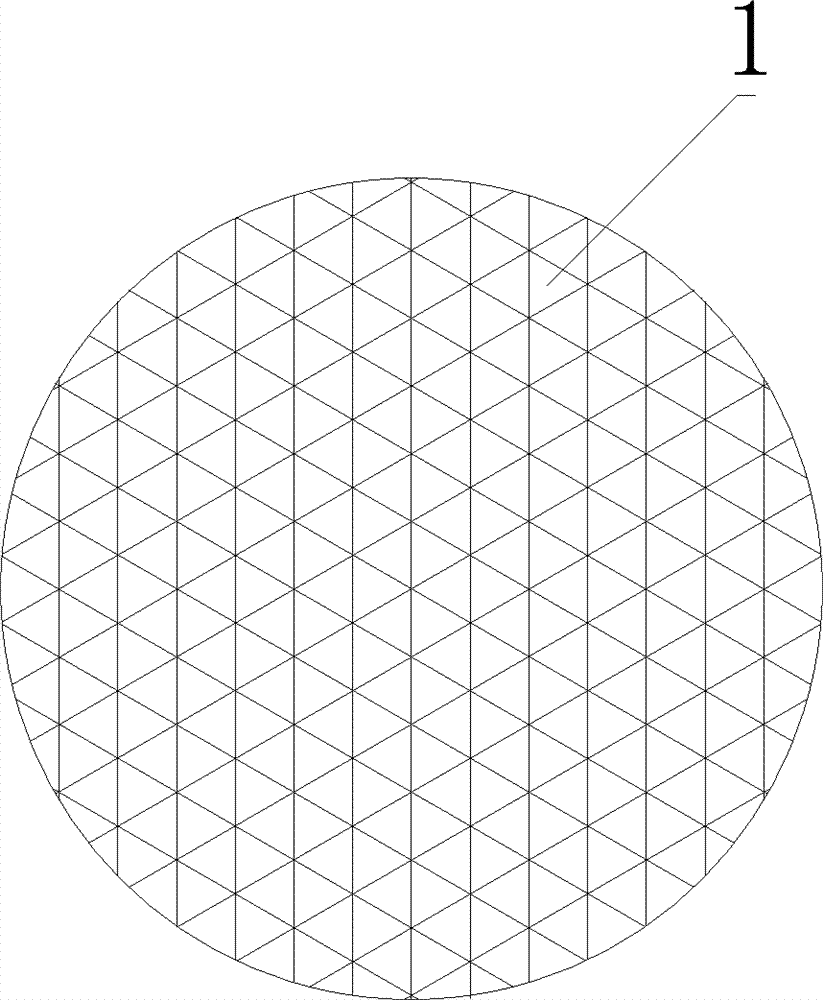

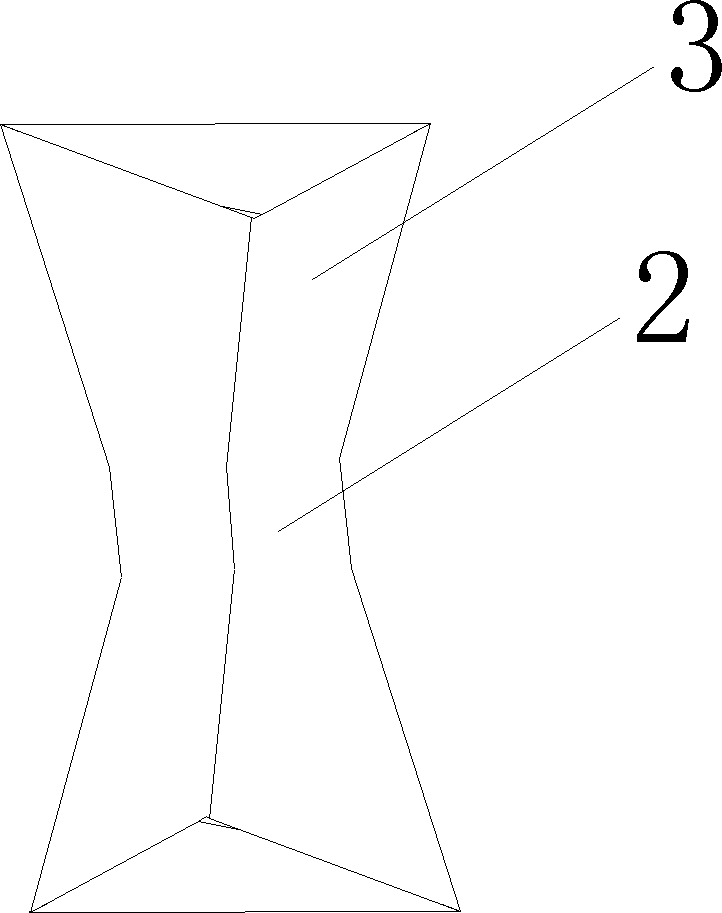

[0026] figure 1 Used mold when preparing the catalyst carrier of the present invention, the mold has a plurality of unit holes, and the outer shape of the catalyst carrier of the present invention is a round cake shape (i.e. flying butterfly shape), consisting of a plurality of unit holes 1 (such as figure 2 shown), the structure of the unit hole is: both ends are polygonal truss structures, and the middle is a continuous hollow necking (ie weir flume), that is, two hollow triangular trusses, four prisms, five prisms or The circular frustum is connected up and down (that is, the structure formed by the connection of two smaller faces in the polygonal frustum), and a continuous hollow neck 2 is formed in the middle of the unit hole 1. The unit hole communicates up and down, and the unit The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com