Composition and method for preparing diamond wire saw with composition

A technology of diamond wire saw and composition, which is applied in the direction of sawing machine tools, manufacturing tools, metal sawing equipment, etc., which can solve the problems of low diamond cutting utilization rate, irregular diamond arrangement, poor processing accuracy, etc., and achieve line marks Shallow, high cutting utilization rate, high processing precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

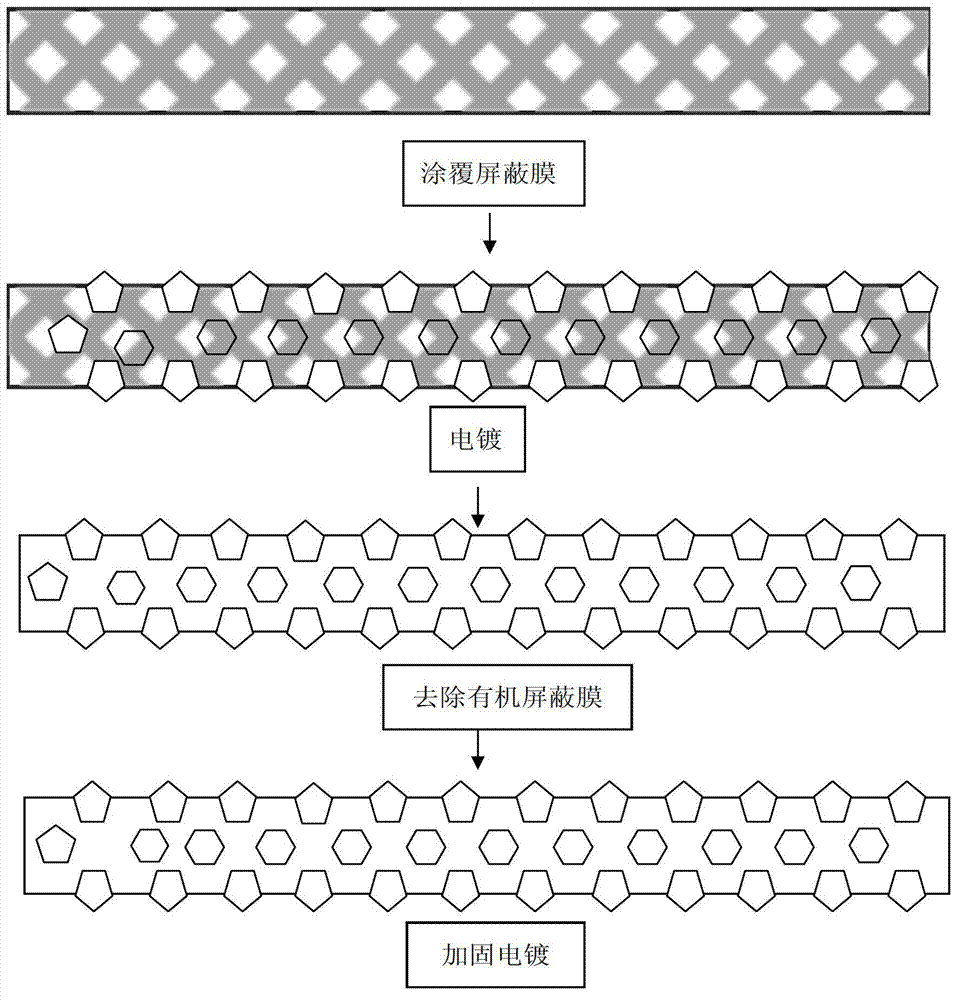

[0033] Another aspect of the present invention also provides a kind of preparation method of diamond wire saw, comprises the following steps:

[0034] Coating the shielding film: coating the aforementioned composition on the surface of the embryonic thread, and forming an organic organic shielding film with regular pores on the surface of the embryonic thread through the curing step to obtain the embryonic thread with an organic shielding film;

[0035] Electroplating: The diamond particles are combined to the pores of the embryonic wire with an organic shielding film by electroplating to obtain a diamond wire saw with an organic shielding film;

[0036] Removing the organic shielding film: immersing the diamond wire saw with the organic shielding film in an organic solvent to remove the organic shielding film to obtain the first product of the diamond wire saw;

[0037] Reinforced electroplating: The diamond wire saw is obtained by performing a reinforced electroplating step ...

Embodiment 1

[0048] Composition 1 includes 95wt% ethyl α-cyanoacrylate, 3wt% tackifier, 1wt% stabilizer, 2wt% polymerization inhibitor.

[0049] (1) Take diamond particles with a particle size of 10-20 μm and a steel wire with a diameter of 0.12 mm, degrease with 10% Na(OH) aqueous solution, rinse with water, and then pickle with 5% aqua regia to remove surface impurities to obtain Clean diamond particles and steel wire.

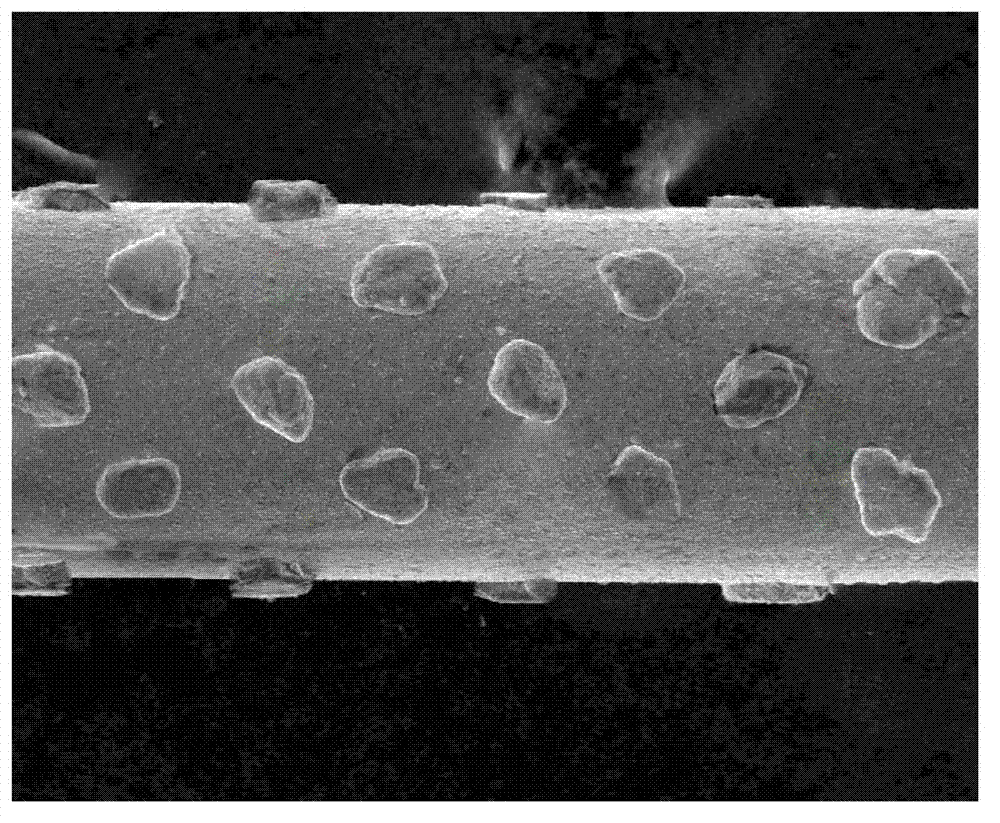

[0050] (2) Coating composition 1 on the surface of a clean steel wire, heating to 80°C, making composition 1 form an organic shielding film with regular pores and a thickness of 1 μm on the surface of the embryo wire to obtain a steel with an organic shielding film Wire.

[0051] (3) Pass the steel wire with an organic shielding film through the electroplating tank at a speed of 20m / min at 40°C, so that the clean diamonds are regularly arranged in the unshielded pores in the steel wire to obtain a diamond wire saw with an organic shielding film .

[0052] (4) Place th...

Embodiment 2

[0055] Composition 2 includes 90wt% ethyl α-cyanoacrylate, 5wt% tackifier, 2wt% stabilizer, 3wt% polymerization inhibitor.

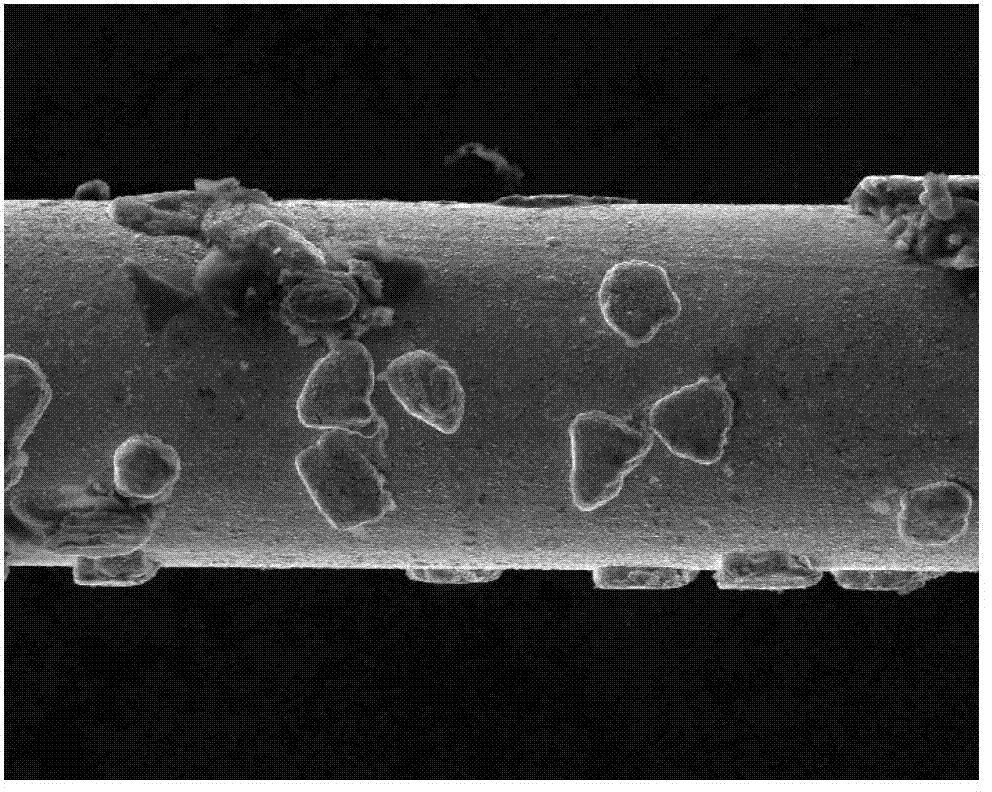

[0056] (1) Take diamond particles with a particle size of 40-50 μm, degrease them with 10% Na(OH) aqueous solution, rinse with water, and then pickle them with 5% aqua regia to remove surface impurities to obtain clean diamond particles.

[0057] (2) Take a steel wire with a diameter of 0.25mm as the embryonic wire, degreasing the embryonic wire in a 5wt% alkaline solution and activating it with 2wt% pickling, derusting and descaling to obtain a clean steel wire.

[0058] (3) Coating composition 2 on the surface of a clean steel wire, heating to 90°C, making composition 2 form an organic shielding film with regular pores and a thickness of 3 μm on the surface of the embryo wire to obtain a steel with an organic shielding film Wire.

[0059] (4) Pass the steel wire with an organic shielding film through the electroplating tank at a speed of 10m / min at 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com