A device for preparing electroplated diamond wire saw

A technology of electroplating diamond and wire saw, applied in the direction of electrolytic coating, coating, etc., can solve the problems of low cutting precision, waste of production equipment space, pollution of electroplating solution, etc., achieve small footprint, consistent wire diameter, and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

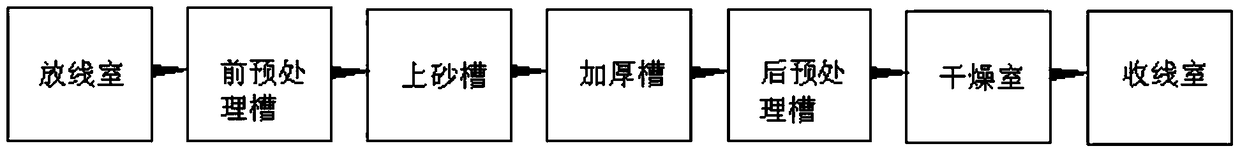

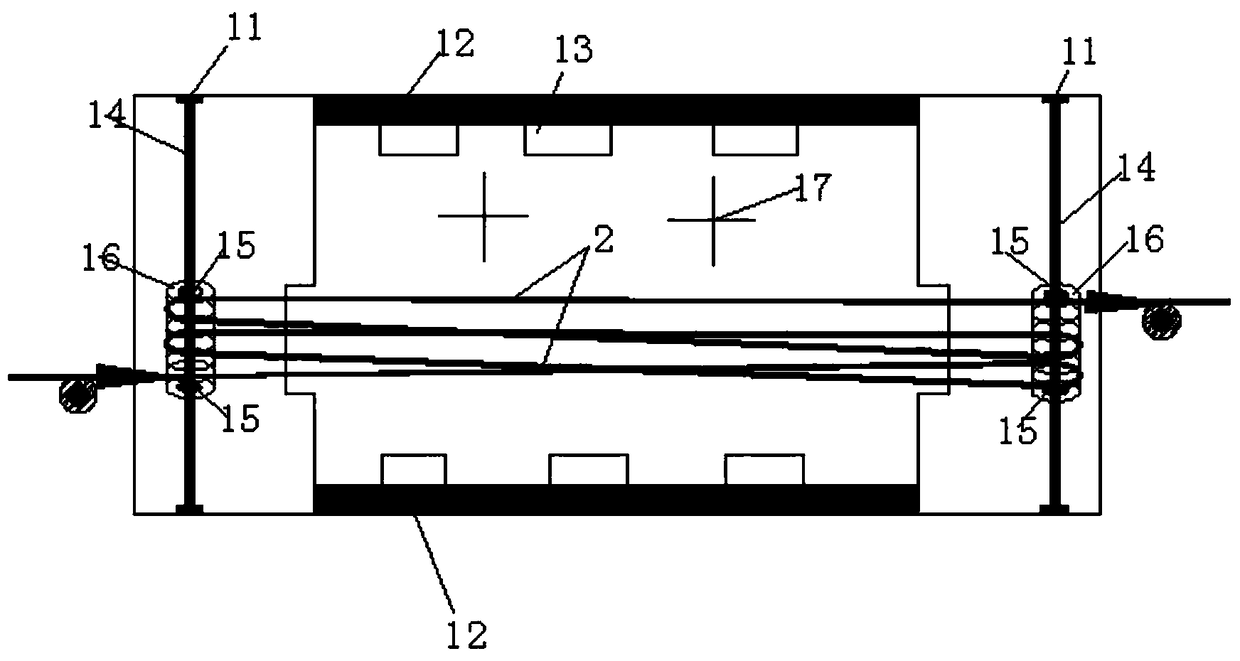

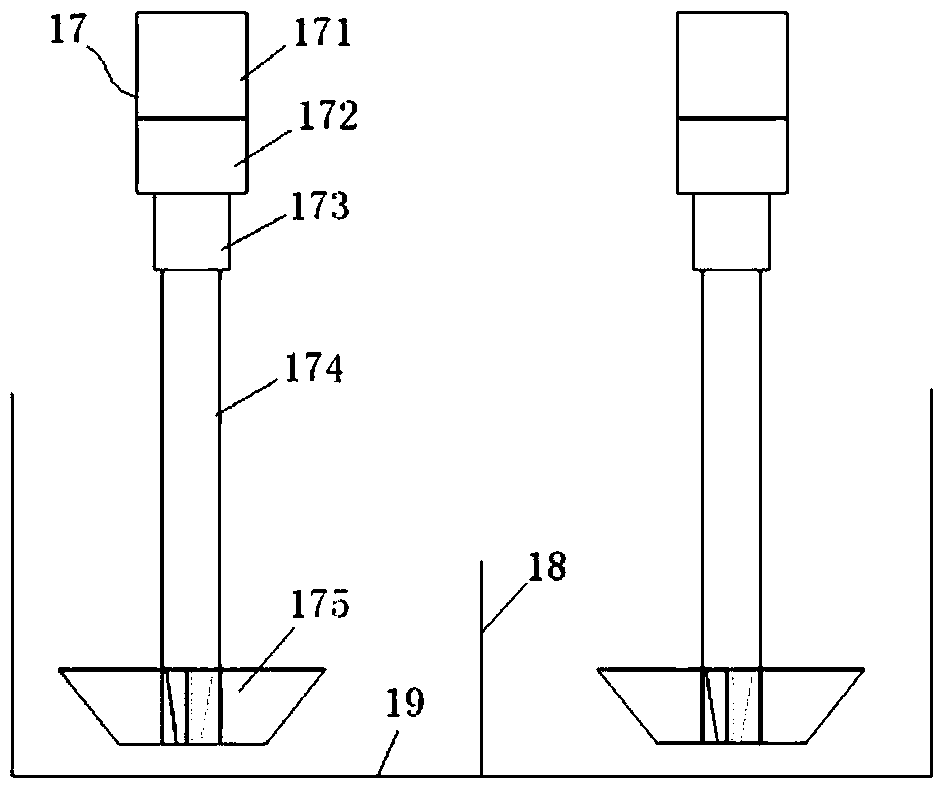

[0034] Such as figure 1 , 2Shown in and 3, a kind of device that prepares electroplated diamond wire saw, comprise pay-off room, front pretreatment tank, upper sand tank, thickening tank, rear pretreatment tank, drying chamber and take-up room, the cathode of upper sand tank 11 Connect the negative pole of the power supply through the conductive shaft 14, the conductive cathode wheel 16 is connected on the conductive shaft 14 through the metal bearing 15, the matrix wire 2 is wound on the conductive cathode wheel 16, and the matrix wire 2 is wound on the cathode wheel 16 of the cathode, so that The matrix wire 2 becomes the negative pole, and the metal bearing 15 adorned between the cathode wheel 16 and the conductive shaft 14 not only ensures good electrical conductivity, but also makes the cathode wheel 16 rotate freely to prevent the matrix wire 2 from breaking. The anode is connected to the copper plate 12 through the positive pole of the current, and the current is trans...

Embodiment 2

[0040] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that when the base line 2 in the upper sand tank is set in the center, the two stirring devices 17 of the upper sand tank are diagonally arranged on the opposite side of the base line 2 of the tank body, The structures of other devices for preparing electroplated diamond wire saws are the same as those in Example 1.

Embodiment 3

[0042] Such as Figure 9 As shown, the difference between this embodiment 3 and embodiment 1 is that four stirring devices 17 are provided in this embodiment 3, which are respectively arranged at the four corners of the tank body, and the separating plate is connected to the inner cavity of the tank body, forming a "ten" " font cross setting, isolates 4 stirring wheels, and the structure of the device of other preparation electroplated diamond wire saws is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com