Injectable type fast curing medical polyurethane compound and preparation method thereof

A fast-curing, polyurethane technology, applied in pharmaceutical formulations, applications, dental preparations, etc., can solve problems such as conversion rate less than 70%, failure of root canal filling, and difficulty in light-curing effect, achieving moisture insensitivity and curing speed Fast, good biocompatibility results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

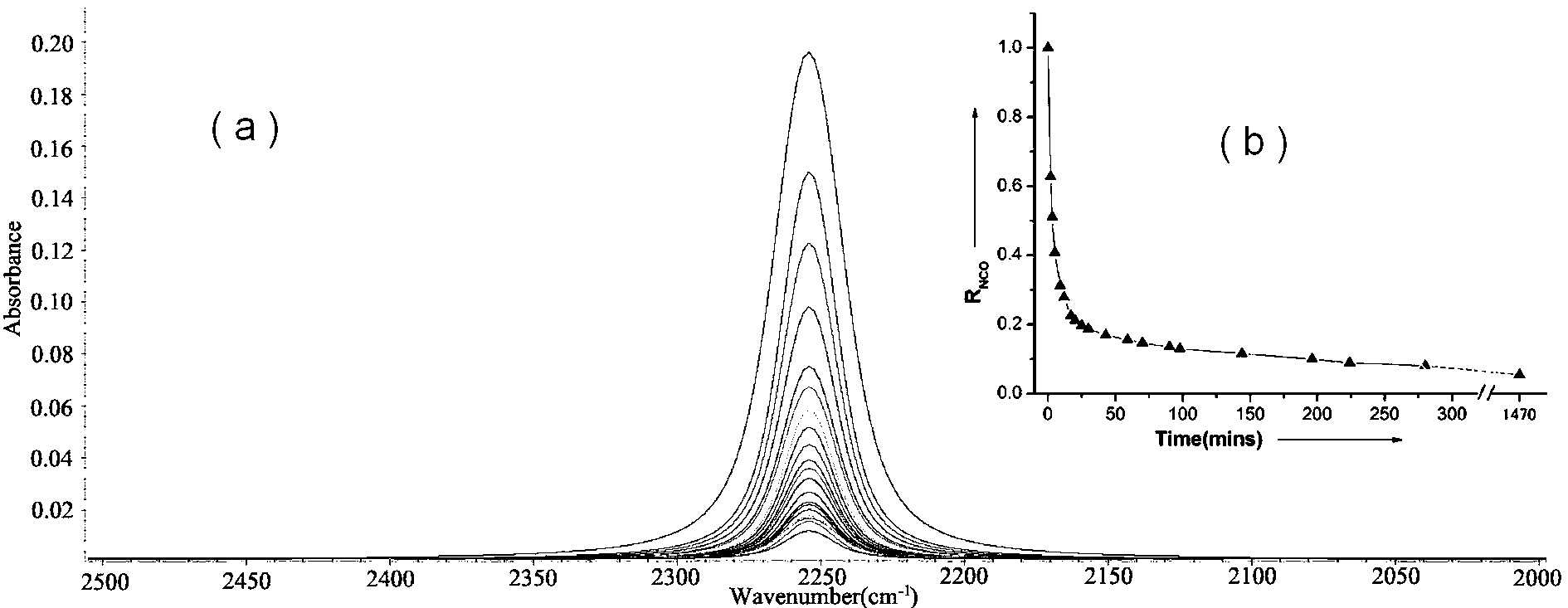

Image

Examples

Embodiment 1

[0038] Add polytetrahydrofuran ether glycol (PTMEG, molecular weight 2000) into a three-neck flask with a stirring device filled with nitrogen, and then add isophorone diisocyanate (IPDI) (the molar ratio of NCO of isocyanate to OH in polyol is 1.5 :1), react at 50~80°C for 5~6 hours, then add chain extender 1, 4 butanediol (the mass ratio of it to PTMEG is 1:45), and continue to stir in a nitrogen environment at a speed of about 60r / min The reaction is carried out to obtain the polyurethane polymer component A with a degree of polymerization of 8-9. Component B was prepared by mixing polyethylene glycol (molecular weight 600), triethanolamine (TEA), and stannous octoate at a mass ratio of 5:1:1. When using, mix A and B components according to the mass ratio of 5:1, stir well for about 1 minute to make it solidify.

[0039] The scanning electron micrographs of the polyurethane composition co-cultivated with mouse fibroblast L929 for three days and five days after being solidi...

Embodiment 2

[0042] Add polytetrahydrofuran ether glycol (PTMEG) (molecular weight 3000) into a three-necked flask with a stirring device filled with nitrogen, add nano-silver powder with a total amount of 3wt%, and then add lysine diisocyanate (NCO of isocyanate and poly The molar ratio of OH in the alcohol is 2:1), react at 50~80°C for 24 hours, then add the chain extender 1, 4 butanediol (the mass ratio of the macromolecule alcohol PTMEG is 1:30), continue to Reaction under a nitrogen environment and stirring at about 50 r / min to obtain a polyurethane polymer component A with a polymerization degree of 9-11. Component B was prepared by mixing polyethylene glycol (molecular weight 400), triethanolamine (TEA), and stannous octoate in a ratio of 2:1:1. When using, mix A and B components according to the mass ratio of 5:1, stir well for about 1 minute to make it solidify.

Embodiment 3

[0044] Add polyethylene glycol (PEG) (molecular weight 4000) into a three-neck flask with a stirring device filled with nitrogen, add nano-hydroxyapatite powder with a total amount of 20wt% (refer to the aforementioned literature for the preparation method), and then add isofor ketone diisocyanate (IPDI) (the molar ratio of NCO of isocyanate to OH in polyol is 1.5:1), react at 50~80°C for 30 hours, and then add chain extender 1,4 butanediol (which is compatible with macromolecule The mass ratio of alcohol PEG is 1:60), continue to react under nitrogen environment and 100r / min stirring, and obtain the polyurethane polymer component A with a polymerization degree of 7~9. Mix glycerol, triethylenediamine, and stannous octoate in a ratio of 4:1:1 to prepare component B. When using, mix A and B components according to the mass ratio of 3:1, stir fully for about 2 minutes to make it solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com