A preparation method of silane-crosslinked halogen-free flame-retardant polyolefin cable material

A polyolefin cable material, silane cross-linking technology, used in insulated cables, cables, circuits, etc., can solve the problems of high pressure, poor flame retardant performance and hand feel, and difficult to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

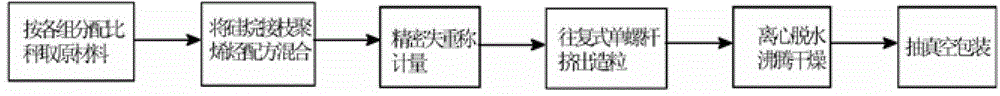

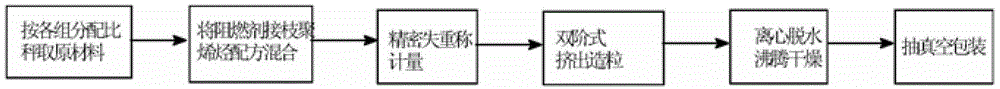

[0058] It relates to a preparation method of a silane-crosslinked halogen-free flame-retardant polyolefin cable material. The preparation method of the halogen-free flame-retardant polyolefin cable material is prepared by two-step silane crosslinking technology. The silane-crosslinked halogen-free flame-retardant The preparation method of polyolefin cable material consists of flame retardant graft A material and catalytic masterbatch B material. Most preferably, the preparation of the flame-retardant graft A material includes the following steps: firstly prepare the silane-grafted polyolefin resin; use the silane-grafted polyolefin resin as raw material, mix it with modified flame retardants, processing aids, etc. The high-precision feeding weight loss system enters the reciprocating single-screw extrusion granulation unit, kneads, shears, and extrudes at 100-150°C, and then granulates with spray granulation. After cooling, centrifugal dehydration, Boiling drying, automatic pa...

Embodiment approach

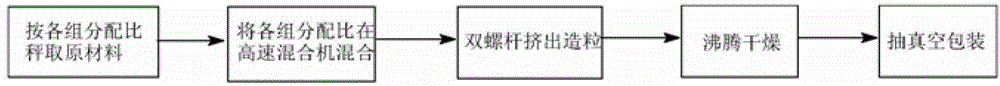

[0130] A method for preparing a silane-crosslinked halogen-free flame-retardant polyolefin cable material, comprising the steps of:

[0131] (1) Preparation of silane-grafted polyolefin: grafting silane onto polyolefin resin to obtain silane-grafted polyolefin;

[0132] (2) Use silane-grafted polyolefin as raw material, mix it with flame retardants, processing aids, etc. according to the ratio, and enter the reciprocating single-screw extrusion granulation unit through the high-precision K-TRON feeding weight loss system. Mixing, shearing and extrusion at -150°C, and then granulation by spray granulation, cooling, centrifugal dehydration, boiling drying, and automatic packaging by an automatic weighing and packaging system.

[0133] (3) Using polyolefin as the main raw material, adding catalysts, antioxidants and other processing aids, mixing for 3-5 minutes, transporting to the twin-screw, mixing and granulating at 140-190°C to obtain material B pellets;

[0134] (4) Dispers...

Embodiment 1

[0163] This example provides a method for preparing a silane-crosslinked low-smoke, halogen-free, flame-retardant polyolefin cable material. The raw materials and dosages used are shown in the table, wherein:

[0164] Ethylene-vinyl acetate resin is an ethylene-vinyl acetate copolymer resin with a vinyl acetate content of 24-28% in the molecule.

[0165] The melt index of the low-density polyethylene resin is 2±0.5g / 10min, produced by Sinopec.

[0166] The silane was Degussa's VTMO.

[0167] The initiator is DCP from Aksu.

[0168] The modified flame retardant is prepared through the following process: aluminum hydroxide is added to a high-speed mixer, and a 2% aluminate coupling agent solution whose mass is aluminum hydroxide is uniformly added under high-speed stirring.

[0169] Antioxidant is Irganox1010 type antioxidant produced by Swiss Ciba Company.

[0170] The melt index of ethylene-octene copolymer is 5g / 10min, and the hardness is 75A.

[0171] The catalyst is dib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com