Novel cerium oxide denitration catalyst and preparation method thereof

A technology of denitrification catalyst and cerium oxide, which is applied in the field of new cerium oxide denitrification catalyst and its preparation, can solve the problems of great impact on catalyst activity and life, pollution of human body and ecological environment, narrow applicable temperature range, etc., and achieve good alkali metal resistance Poisoning performance, reduced operating costs, and good high airspeed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

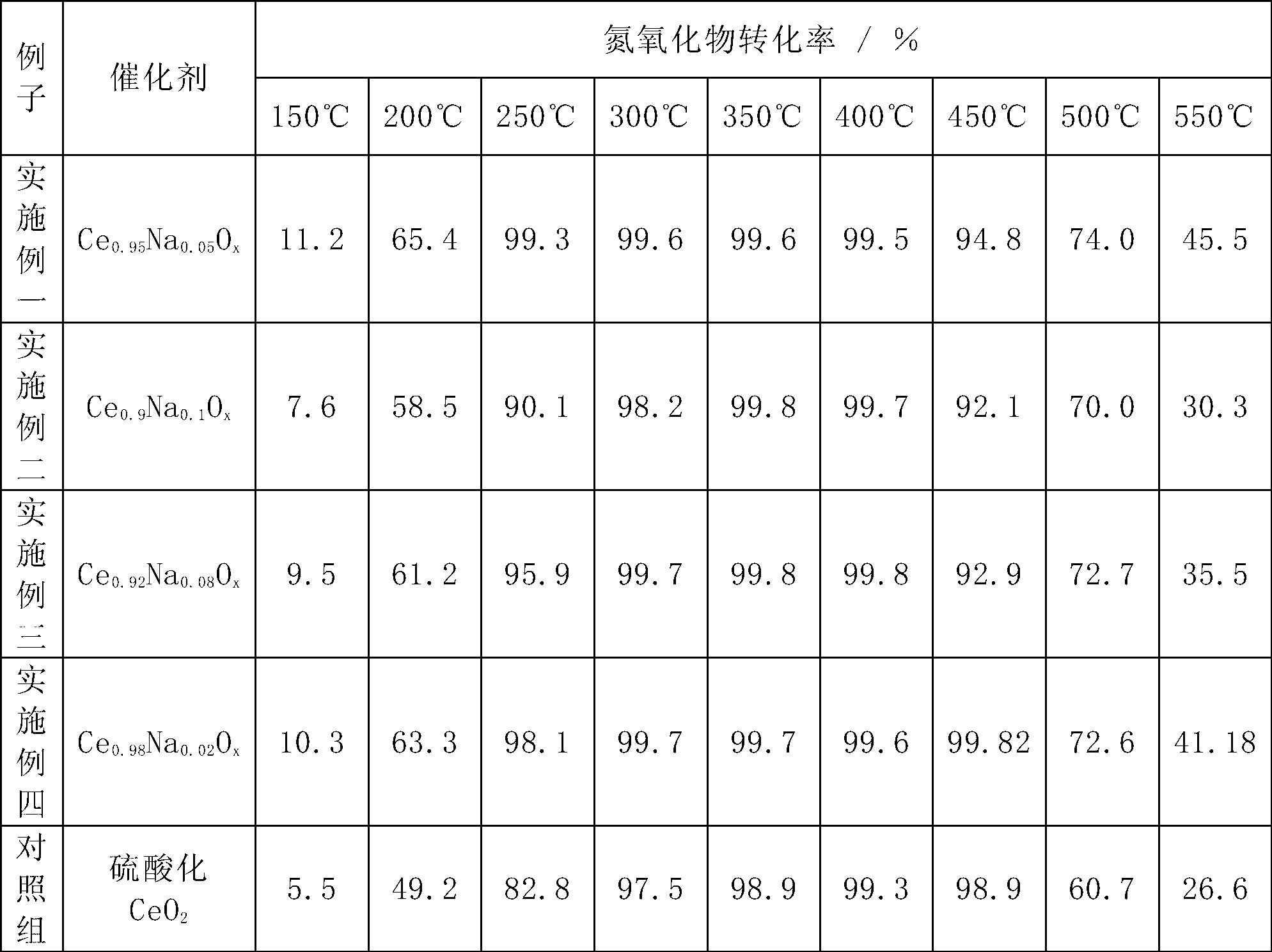

[0022] A preparation method of a cerium-based low-temperature denitration catalyst, comprising the following steps:

[0023] Step 1. Dissolve cerium sulfate, sodium phosphate and cerous sulfate in water of 10 times the mass at room temperature, and stir to form a transparent solution, wherein the content of cerium sulfate is 80% of the molar percentage of the catalyst, and the content of sodium phosphate is the molar percentage of the catalyst 5%, the balance is cerous sulfate;

[0024] Step 2. Transfer the solution prepared in step 1 to a hydrothermal reactor with a capacity of 100 mL, and add deionized water to 70% of the total volume of the hydrothermal reactor;

[0025] Step 3. Seal the hydrothermal reaction kettle in step 2 and transfer it to an oven to heat and react at 200° C. for 12 hours. After cooling down, centrifuge and wash with deionized water until the presence of sulfate groups cannot be detected;

[0026] Step 4. Dry the centrifuged precipitate in an oven at ...

Embodiment 2

[0030] A cerium-based low-temperature denitrification catalyst, the raw material components of which are: cerium sulfate with a content of 85% of the molar percentage of the catalyst, sodium phosphate with a content of 10% of the molar percentage of the catalyst, and a content of 10% of the molar percentage of the catalyst 5% cerium sulfate.

[0031] A preparation method of a cerium-based low-temperature denitration catalyst, comprising the following steps:

[0032] Step 1. Dissolve cerium sulfate, sodium phosphate and cerous sulfate in water of 20 times the mass at room temperature, and stir to form a transparent solution, wherein the content of cerium sulfate is 85% of the molar percentage of the catalyst, and the content of sodium phosphate is the molar percentage of the catalyst 10%, the balance is cerous sulfate;

[0033] Step 2. Transfer the solution prepared in step 1 to a hydrothermal reactor with a capacity of 100 mL, and add deionized water to 70% of the total volum...

Embodiment 1

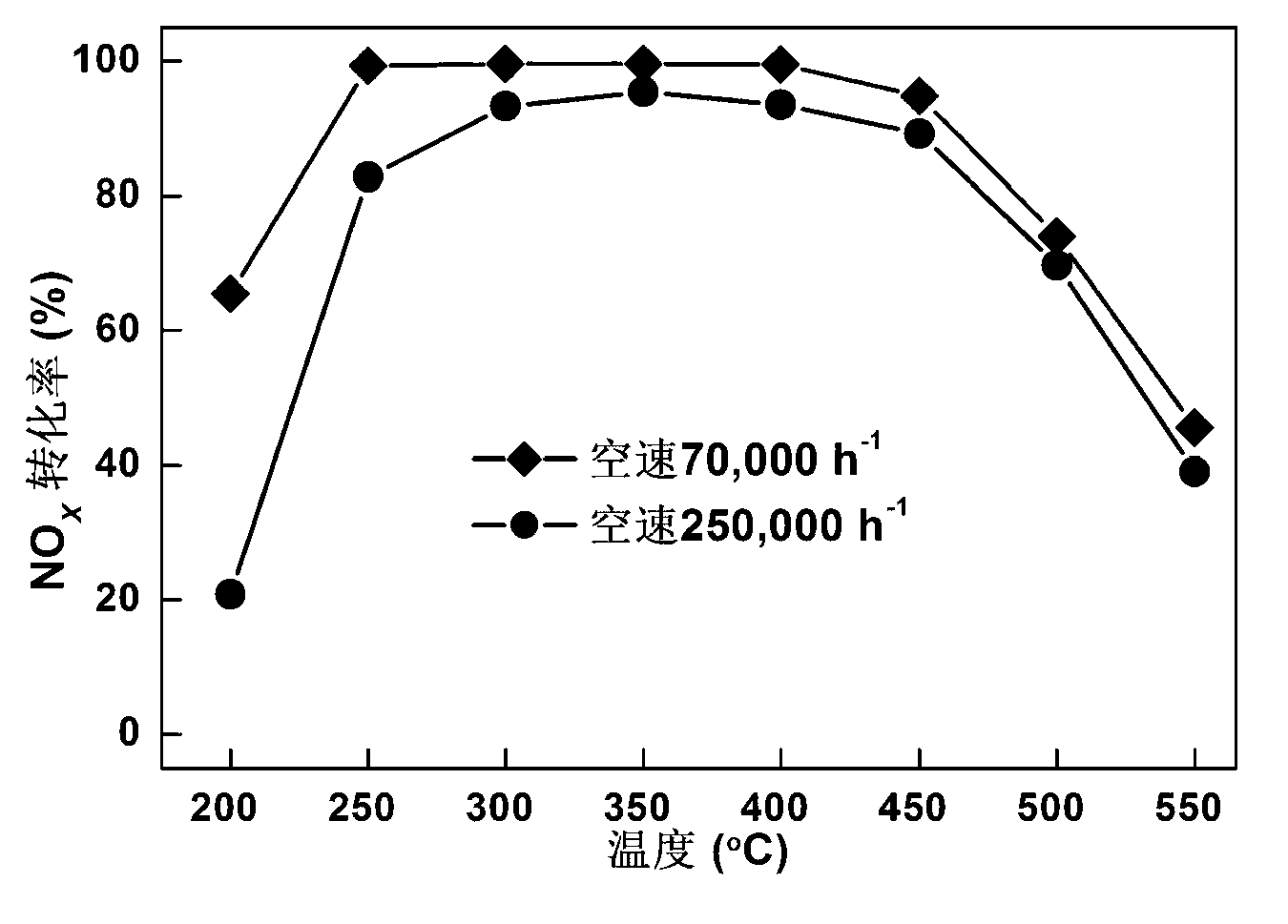

[0038] The catalyst prepared in Example 1 was reacted when ammonia was used as a reducing agent: 500ppm of nitrogen monoxide (NO), 500ppm of ammonia (NH 3 ), 5% oxygen (O 2 ) mixed, and the rest of the reaction mixture is nitrogen (N 2 ), by installing 150mg of the composite oxide catalyst, the reaction space velocity is 70000h -1 , in a wide temperature range (200-500 °C), the efficient and selective catalytic reduction of NO can be achieved.

[0039] 500ppm of nitric oxide (NO), 500ppm of ammonia (NH 3 ), 5% oxygen (O 2 ) mixed, and the rest of the reaction mixture is nitrogen (N 2 ), through the reaction tube equipped with 150mg of the composite oxide catalyst, the reaction space velocity is 250000h -1 , and the temperature range is 200-550 °C, the conversion rate of the catalyst prepared in this example to reduce nitrogen oxides is shown in the attached figure 1 .

[0040] From figure 1 It can be seen from the figure that the increase of space velocity has a signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com