Preparation method of foamy copper/carbon nanophase composite negative electrode material for lithium ion battery

An ion battery and negative electrode material technology is applied in the field of preparation of lithium ion battery electrodes, and achieves the effects of low cost, simple preparation process, and easy realization and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

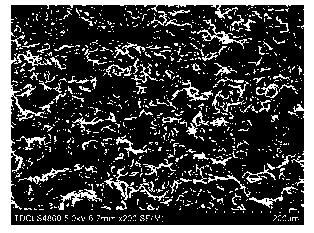

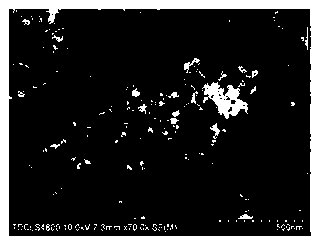

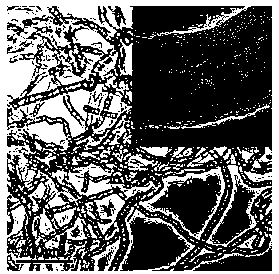

[0034] 10g of NaCl particles were milled for 60min at a ball-to-material ratio of 20:1, at a rotational speed of 500rpm, to obtain NaCl particles with an average particle size of 40μm, and 2.41g of NaCl particles with a particle size of 40μm were mixed with 10g of electrolytic copper powder and 5mL of absolute ethanol. Put it into a V-type drum mixer, the speed is 80r / min, the mixing time is 3h, and then take the mixture of 30mgNaCl and copper powder and put it into a press with a size of Φ12 × 0.14mm 3 In the die, pressurize to 300MPa in one direction to obtain the billet. Put the billet prepared above in a tube furnace, under the protective atmosphere of argon, raise the temperature to 760°C at a rate of 10°C / min, hold the time for 2h, then heat it up to 940°C for 3h, also with Cool down to room temperature with the furnace at a cooling rate of 10°C / min. Take out the sample and place it in a circulating hot water device at 80°C to dissolve NaCl, then place it in an oven and...

Embodiment 2

[0038] 10g of NaCl particles were milled for 90 minutes at a ball-to-material ratio of 20:1, at a speed of 300 rpm, to obtain NaCl particles with an average particle size of 70 μm. Take 3.62 g of NaCl particles with a particle size of 70 μm and 10 g of electrolytic copper powder with a particle size of 200 mesh and Put 6mL of absolute ethanol into a V-shaped drum mixer with a rotation speed of 80r / min and a mixing time of 2h, then take a mixture of 38mgNaCl and copper powder and fill it with a size of Φ12×0.20mm 3 In a pressing die, the blank was obtained by unidirectionally pressing to 300MPa. Put the billet prepared above in a tube furnace, and in a protective atmosphere of argon, raise the temperature to 750°C at a rate of 10°C / min, hold for 2h, then raise the temperature to 950°C for 3h, the same with Cool down to room temperature with the furnace at a cooling rate of 10°C / min. Take out the sample and place it in a circulating hot water device at 80°C to dissolve the NaCl...

Embodiment 3

[0042] 10g of NaCl particles were milled for 90 minutes at a ball-to-material ratio of 20:1, at a speed of 400 rpm, to obtain NaCl particles with an average particle size of 60 μm. Take 5.60 g of NaCl particles with a particle size of 60 μm and 10 g of electrolytic copper powder with a particle size of 200 mesh and Put 6mL of absolute ethanol into a V-shaped drum mixer with a rotation speed of 80r / min and a mixing time of 4h, then take a mixture of 46mg of NaCl and copper powder and fill it with a size of Φ12 × 0.34mm 3 In a pressing die, pressurize unidirectionally to 300MPa to obtain a billet. Place the billet prepared above in a tube furnace, and in a protective atmosphere of argon, raise the temperature to 740°C at a rate of 8°C / min for a holding time of 3h, and then heat it up to 940°C for 1.5h. Cool down to room temperature with the furnace at a cooling rate of 10°C / min. The sample was taken out and placed in a circulating hot water device at 50°C to dissolve the NaCl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com