Etching solution composition and etching method for copper and copper alloy

A technology of composition and etching solution, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of not obtaining shapes, etc., and achieve excellent practicability, high in-plane uniformity, and increased etching rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~53

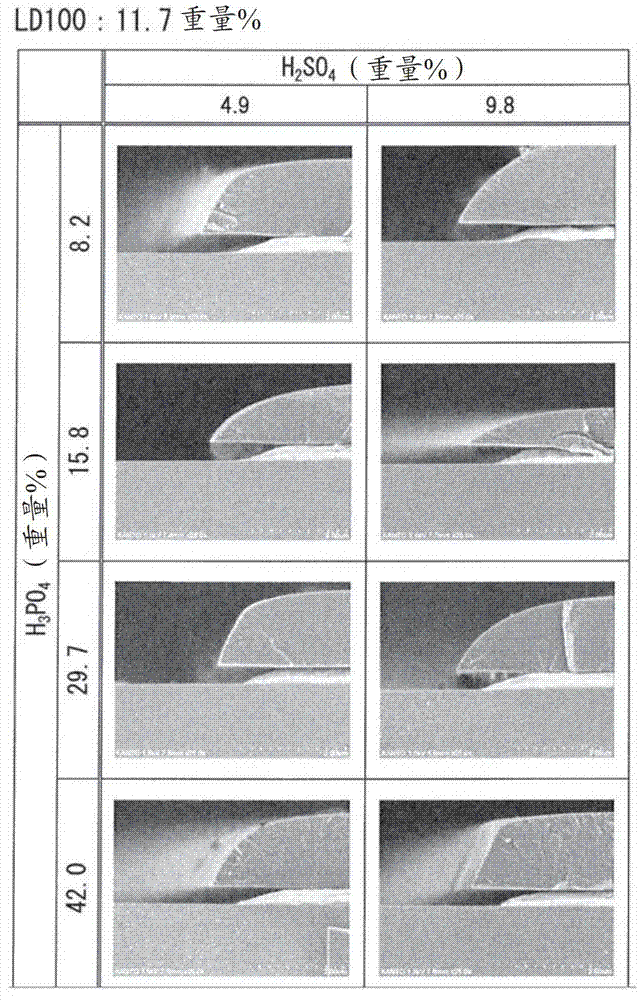

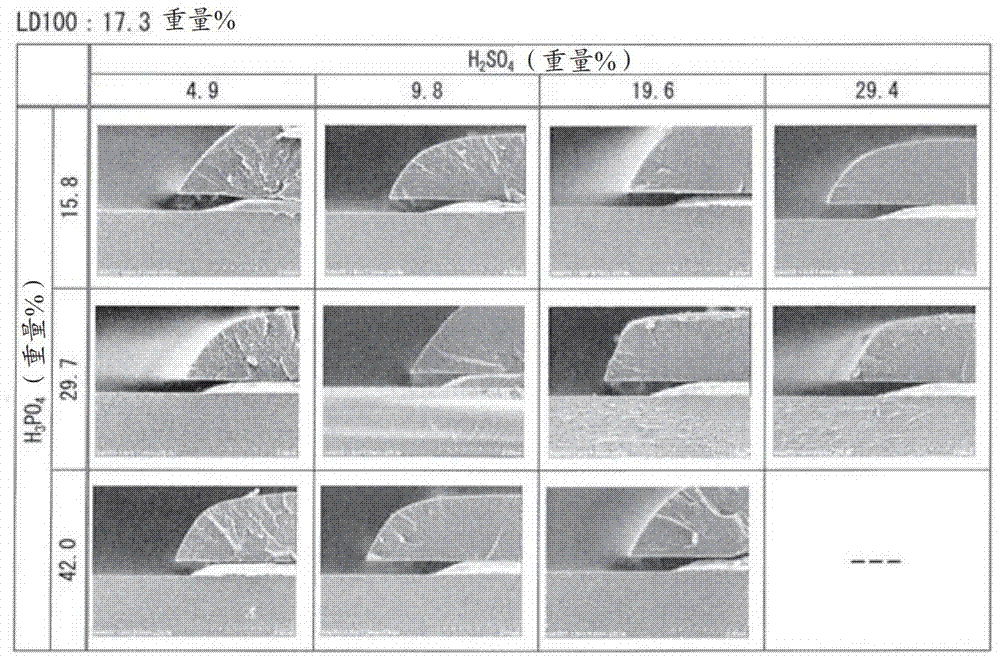

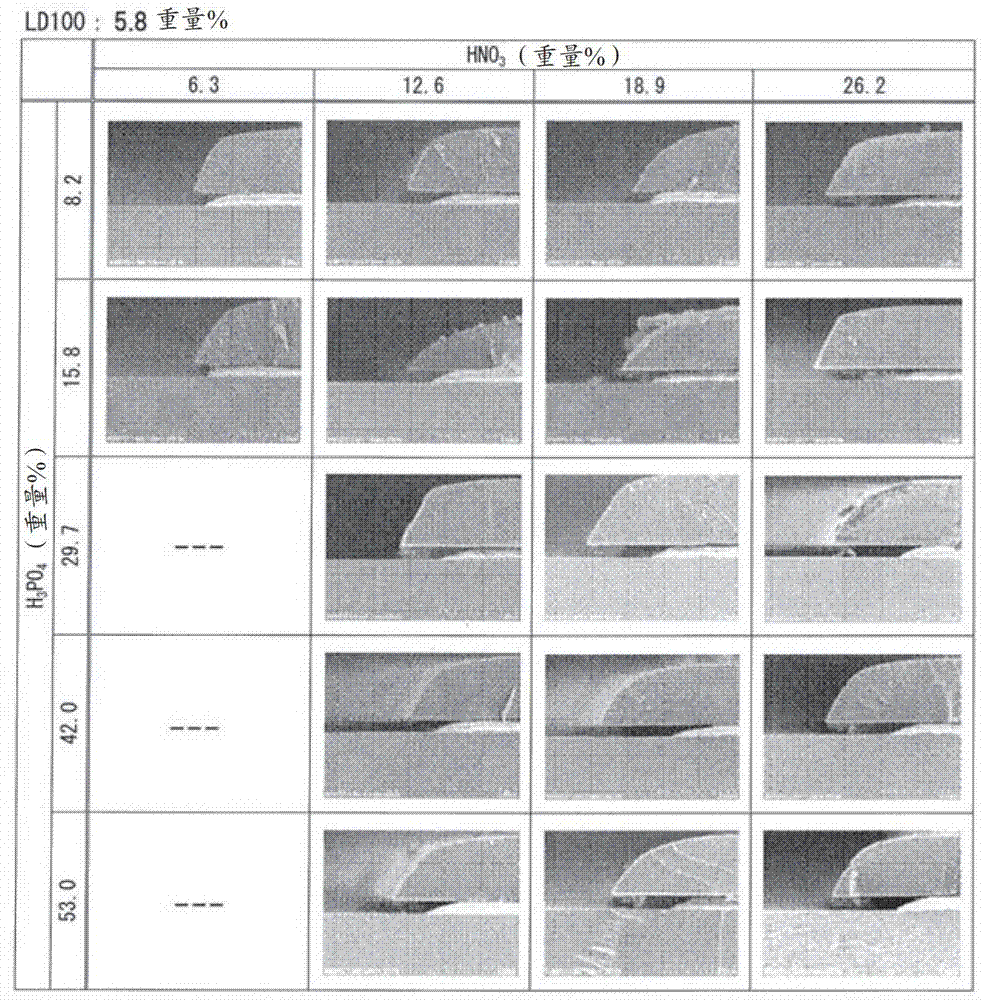

[0082] pair on glass substrate thick Cu alloy (Cu-Mg-Al), After forming a thick Cu film, a protective layer pattern was formed and dipped in the etching solution shown in Tables 1 to 4 at a liquid temperature of 30° C. for 1.5 times the appropriate etching time. Then, it was washed with water, dried, and the residue was evaluated. Moreover, the persulfuric acid solution uses LD100 produced by DuPont (referred to as KHSO 5 solution as the main component).

[0083] The results are shown in Tables 1-4. and, Figure 1 ~ Figure 3 SEM photographs of Tables 1 to 3 are shown, respectively.

[0084] [Table 1]

[0085] Evaluation results of various compositions [J.E.T.×1.5]

[0086] Cu / CuMgAl substrate

[0087]

[0088] [Table 2]

[0089] Evaluation results of various compositions [J.E.T.×1.5]

[0090] Cu / CuMgAl substrate

[0091]

[0092] [table 3]

[0093] Evaluation results of various compositions [J.E.T.×1.5]

[0094] Cu / CuMgAl substrate

[0095]

[0096] [T...

Embodiment 54

[0102] Films were formed on glass substrates thick Cu alloy (Cu-Mg-Al), Thick Cu substrates and films formed on glass substrates thick Cu alloy (Cu-Mg-Al), A protective layer pattern was formed on a thick Cu substrate, and dipped in the etching solution shown in Table 5 at a liquid temperature of 30°C, 40°C, and 50°C for 1.5 times the appropriate etching time. Then, it washed with water, dried, and evaluated the residue. Moreover, the persulfuric acid solution uses LD100 produced by DuPont (referred to as KHSO 5 solution as the main component).

[0103] The results are shown in Table 6, and the SEM photo results of Table 6 are shown in Figure 4 .

[0104] [table 5]

[0105] composition

[0106]

LD100(weight%)

HNO 3 (weight%)

h 3 PO 4 (weight%)

Example 54

11.7

3.2

8.2

[0107] [Table 6]

[0108] Evaluation results of various compositions [J.E.T.×1.5]

[0109] Cu / CuMgAl substrate

[0110]

[0111] Usi...

Embodiment 55~58

[0113] pair on glass substrate thick Cu alloy (Cu-Mg-Al), After forming a thick Cu film, a protective layer pattern was formed, and as shown in Table 7, the etchant of Example 55 was made alkaline, and the cross-sectional shape and residue when hydrochloric acid was added were evaluated. Furthermore, immersion was performed at a liquid temperature of 30° C. for a time 1.5 times the appropriate etching time. In addition, the persulfuric acid solution uses LD100 produced by DuPont (referred to as KHSO 5 solution as the main component).

[0114] The results are shown in Table 8, and the SEM photo results of Table 8 are shown in Figure 5 .

[0115] [Table 7]

[0116]various composition

[0117]

[0118] [Table 8]

[0119] Evaluation results of various compositions [J.E.T.×1.5]

[0120] Cu / CuMgAl substrate

[0121]

[0122] The cross-sectional shape of the composition of Example 55 was confirmed when the concentration of hydrochloric acid was changed under alkalin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com