Sn-Cu-Ni-Ce-Cr lead-free solder and preparation method thereof

A sn-cu-ni-ce-cr, lead-free solder technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of reducing solder slag rate, poor oxidation resistance, etc. The effect of improving high temperature oxidation resistance, improving wetting properties, reducing the possibility of chemical corrosion and galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

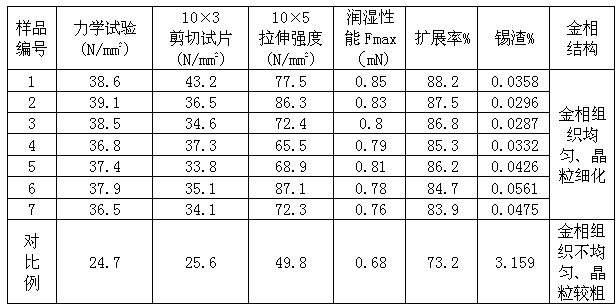

Examples

Embodiment 1

[0020] Get 50kg of tin-copper alloy ingots described in the preparation method provided by the invention, 10kg of tin-chromium alloy ingots, 10kg of tin-cerium alloy ingots, 1.5kg of tin-nickel alloy ingots and 28.5kg of the insufficient tin amount of the poor surplus tin and add stainless steel pot Carry out smelting in, cast into lead-free solder, obtain the product of the present invention that is originally made by tin 92.85%, copper 5%, chromium 1%, cerium 1%, nickel 0.15%.

Embodiment 2

[0022] Get 40kg of tin-copper alloy ingots described in the preparation method provided by the invention, 8kg of tin-chromium alloy ingots, 0.8kg of tin-cerium alloy ingots, 0.8kg of tin-nickel alloy ingots and 50.4kg of insufficient tin amount to add surplus tin and add stainless steel The pot is melted and cast into lead-free solder to obtain the product of the present invention made of 95.04% tin, 4% copper, 0.8% chromium, 0.08% cerium and 0.08% nickel as raw materials.

Embodiment 3

[0024] Get 30kg of tin-copper alloy ingots described in the preparation method provided by the invention, 5kg of tin-chromium alloy ingots, 8kg of tin-cerium alloy ingots, 1.2kg of tin-nickel alloy ingots and 55.8kg of insufficient tin amount to add surplus tin and add stainless steel pot Smelting in the furnace, casting into lead-free solder, obtaining the product of the present invention made of 95.58% tin, 3% copper, 0.5% chromium, 0.8% cerium, and 0.12% nickel as raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com