Graphene Nitrogen Atom Replacement Doping Method and Prepared Graphene and Application of the Method in Improving Graphene Mass Specific Capacitance

A graphene and nitrogen atom technology, which is applied in hybrid capacitor electrodes, circuits, electrical components, etc., can solve the problem that the nitrogen content of nitrogen-doped graphene is difficult to control, nitrogen-doped graphene loses its planar structure, and nitrogen-doped graphene is unstable, etc. problems, to achieve the effect of increasing the carrier concentration, avoiding chemical reagents, and avoiding pseudocapacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

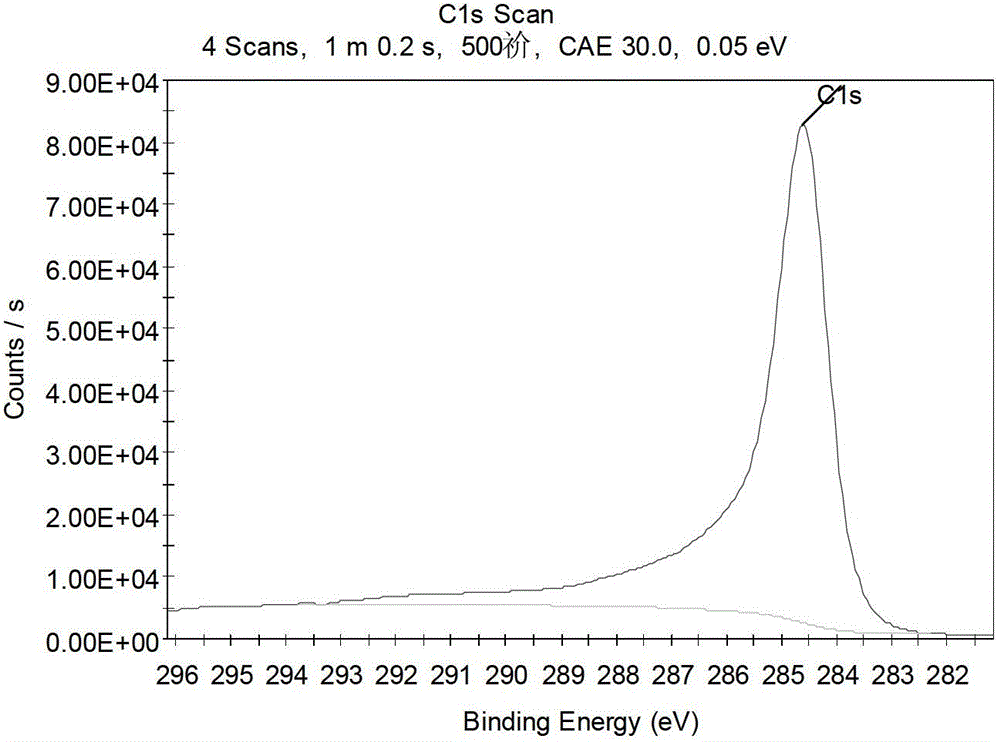

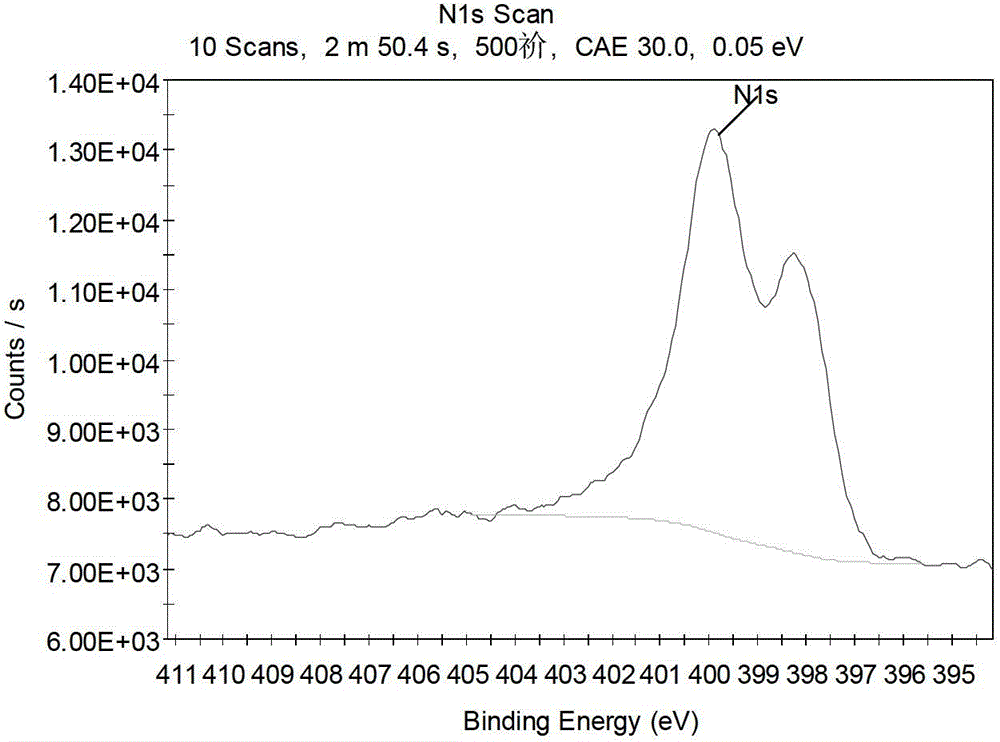

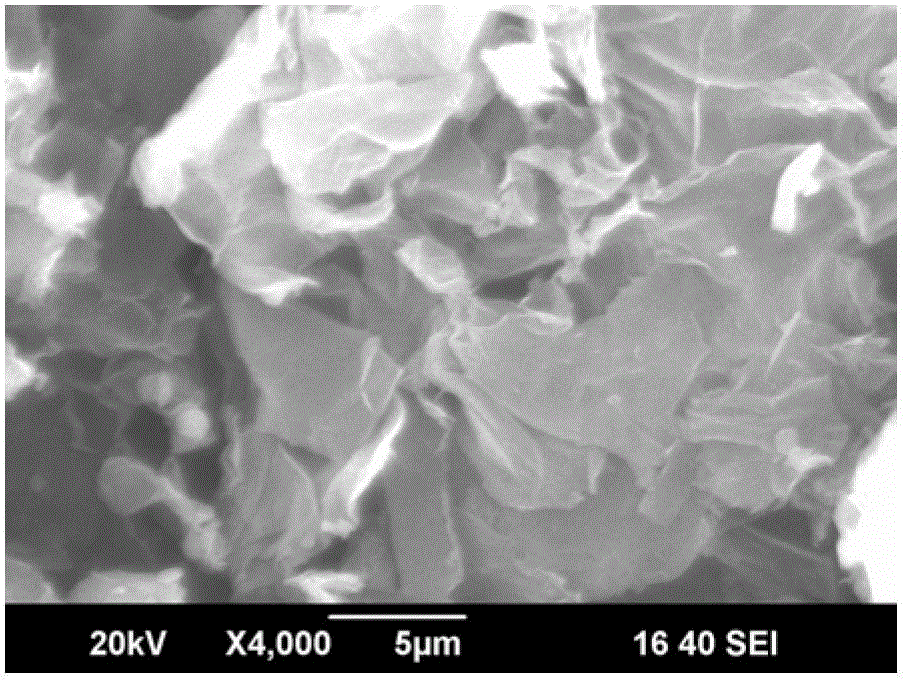

[0060] A nitrogen atom substitution doped graphene with a nitrogen content of 8% and a specific surface area of 2970.8m 2 / g.

[0061] Its preparation method is to carry out the reduction reaction of doping with nitrogen while activating graphene, and the specific operation is as follows:

[0062] 1. Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling;

[0063] 2. Then weigh 500mg graphene oxide powder and dissolve it in 25ml 0.1g / mL KOH solution, fully stir and dry;

[0064] 3. Put the graphene oxide-KOH mixture in a vacuum tube furnace. After removing the air in the furnace, 3 Argon gas with a purity of 99.99% is fed into the vacuum tube furnace at a flow rate of / min. In an inert atmosphere, the temperature is first raised to 800°C, and the temperature is kept constant. 3 Ammonia gas was introduced at a flow rate of 800°C for 10 minutes;

[0065] 4. After the reaction is completed, the temperature is natural...

Embodiment 2

[0069] A nitrogen atom substitution doped graphene with a nitrogen content of 6% and a specific surface area of 2110.6m 2 / g.

[0070] Its preparation method is to carry out the same nitrogen doping reduction reaction while activating graphene, and the specific operation is as follows:

[0071] 1. Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling;

[0072] 2. Then weigh 300mg graphene oxide powder and dissolve it in 20ml 0.6g / mL KOH solution, fully stir and dry;

[0073] 3. Put the graphene oxide-KOH mixture in a vacuum tube furnace. After removing the air in the furnace, 3 The flow rate per minute is to feed argon with a purity of 99.99% into the vacuum tube furnace, first raise the temperature to 1000°C, keep the temperature constant, and then increase 3 Ammonia gas is fed at a flow rate of 1000°C for 5 minutes;

[0074] 4. After the reaction is completed, the temperature is naturally cooled to room tempera...

Embodiment 3

[0078] A nitrogen atom substitution doped graphene with a nitrogen content of 9% and a specific surface area of 2300.3m 2 / g.

[0079] Its preparation method is to carry out the same nitrogen doping reduction reaction while activating graphene, and the specific operation is as follows:

[0080] 1. Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling;

[0081] 2. Then weigh 350mg graphene oxide powder and dissolve it in 20ml 1.4g / mL KOH solution, fully stir and dry;

[0082] 3. Put the graphene oxide-KOH mixture in a vacuum tube furnace, with a distance of 180cm 3 The nitrogen gas with a purity of 99.999% is introduced into the vacuum tube furnace at a flow rate of / min, and the temperature is first raised to 900°C, and then the 3 Ammonia gas was introduced at a flow rate of / min, and calcined at a high temperature of 900°C for 10 minutes;

[0083] 4. After the reaction is completed, the temperature is naturally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com