Nonionic self-emulsifying waterborne epoxy resin and preparation method and application thereof

A water-based epoxy resin, non-ionic technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of self-polymerization, easy ring opening of epoxy resin, and reduced storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

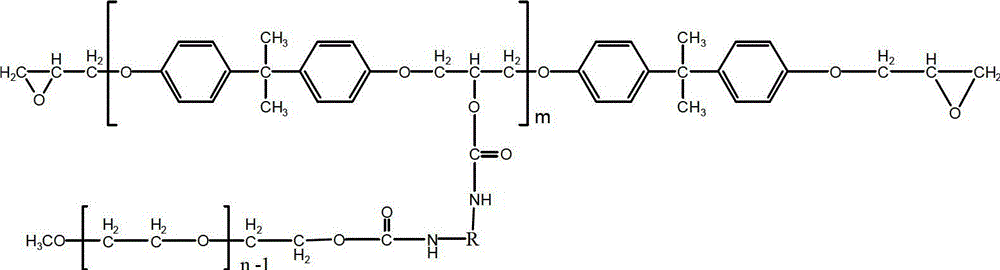

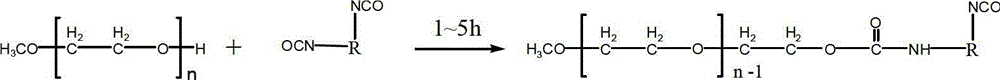

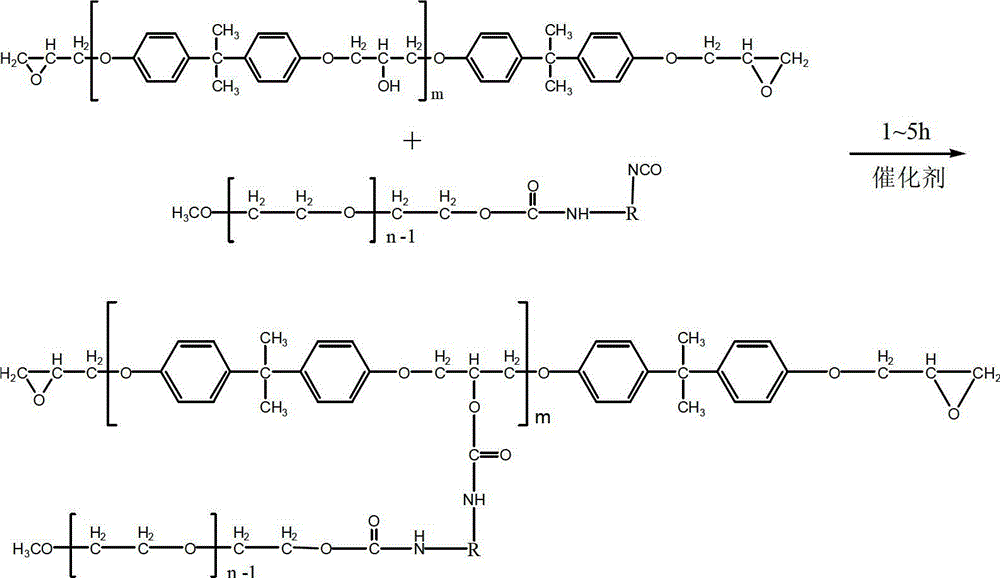

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of nonionic self-emulsifying water-based epoxy resin, comprising the following steps: adding 25 grams of 2,6-toluene diisocyanate (TDI) to a dry three-necked flask equipped with a stirring and temperature control device, 100 grams of polyethylene Glycol monomethyl ether 800, 3 grams of mass fraction is 4% acetyl chloroacetone solution, reacted at 50 DEG C for 5 hours, and the relative content of isocyanic acid value in the system drops to about 50% of the original; Oxygen resin E-44 200 grams, after stirring evenly, add 2 grams of hexa-n-butyl ditin, react at 85 ° C for two hours, the isocyanate value in the system is close to zero, the reaction is terminated, and a non-ionic self-emulsifying water-based ring is obtained. oxygen resin.

[0031] An application of the above-mentioned nonionic self-emulsifying water-based epoxy resin, that is, the preparation of water-based epoxy varnish: 100 grams of the prepared water-based epoxy resin is stirred wit...

Embodiment 2

[0040] A preparation method of nonionic self-emulsifying water-based epoxy resin, comprising the steps of: adding 25 grams of diphenylmethane diisocyanate MDI, 50 grams of polyethylene glycol monomethyl Ether 600, 2.5 grams of acetyl chloroacetone solution with a mass fraction of 4%, reacted for 2 hours at 55°C, and the relative content of the isocyanate value in the system dropped to about 50% of the original; then add epoxy resin E- 44100 grams, after stirring evenly, add 1.5 grams of tetrapropyl tin, react at 75 ° C for two hours, the isocyanate value in the system is close to zero, the reaction is terminated, and a non-ionic self-emulsifying water-based epoxy resin is obtained.

[0041] An application of the above-mentioned nonionic self-emulsifying water-based epoxy resin, that is, the preparation of water-based epoxy varnish; 100 grams of the prepared water-based epoxy resin is stirred evenly with 50 grams of epoxy resin E51, and then 150 grams of water are added , it wa...

Embodiment 3

[0049] A preparation method of nonionic self-emulsifying water-based epoxy resin, comprising the steps of: adding 20 grams of isophorone diisocyanate IPDI, 60 grams of polyethylene glycol mono Methyl ether 800, 2 grams of acetyl chloroacetone solution with a mass fraction of 4%, reacted at 45°C for 2 hours, and the relative content of isocyanic acid value in the system dropped to about 50% of the original; then add epoxy resin E to the system -44160 grams, after stirring evenly, add 2 grams of dibutyltin dilaurate, react at 80°C for two hours, the isocyanate value content in the system is close to zero, and the reaction is terminated to obtain a nonionic self-emulsifying water-based epoxy resin.

[0050] A kind of application with the above-mentioned nonionic self-emulsifying water-based epoxy resin, that is, the preparation of water-based epoxy varnish: 100 grams of the prepared water-based epoxy resin, add 100 grams of water, and use the agitator speed to be 1000 rpm. It was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com