Core-shell organic silicon durable paint and preparation method thereof

A production method, silicone technology, applied in the direction of coating, etc., can solve the problems of high manufacturing cost, long production cycle, complicated process flow, etc., and achieve the effect of low manufacturing cost, simple manufacturing process and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

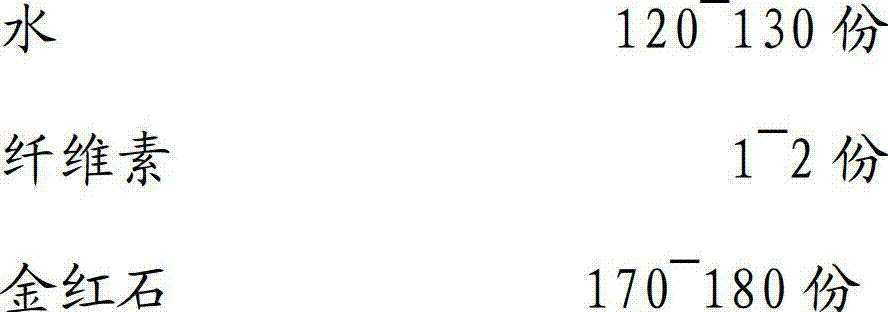

[0013] The core-shell silicone durable coating is made of the following raw materials in parts by weight:

[0014]

[0015]

[0016] The production method of the core-shell silicone durable coating is to add the above-mentioned parts by weight of water, cellulose, rutile, calcined kaolin, precipitated barium sulfate, mica powder, heavy calcium and ethylene glycol in a closed pressure vessel and use it at 70°C. Hydrothermal mixed nucleation, reaction time 30min, then add the dispersant DP270, fungicide XG-405, paint defoamer NXZ, functional additive AMP-95, functional additive 2100, Film-forming aids, thickener TT-936, leveling agent HEUR-D and preservatives are added to polymerize at the same time, evenly stirred, matured, and the viscosity is adjusted. After passing the technical index inspection, it is measured and packaged.

Embodiment 2

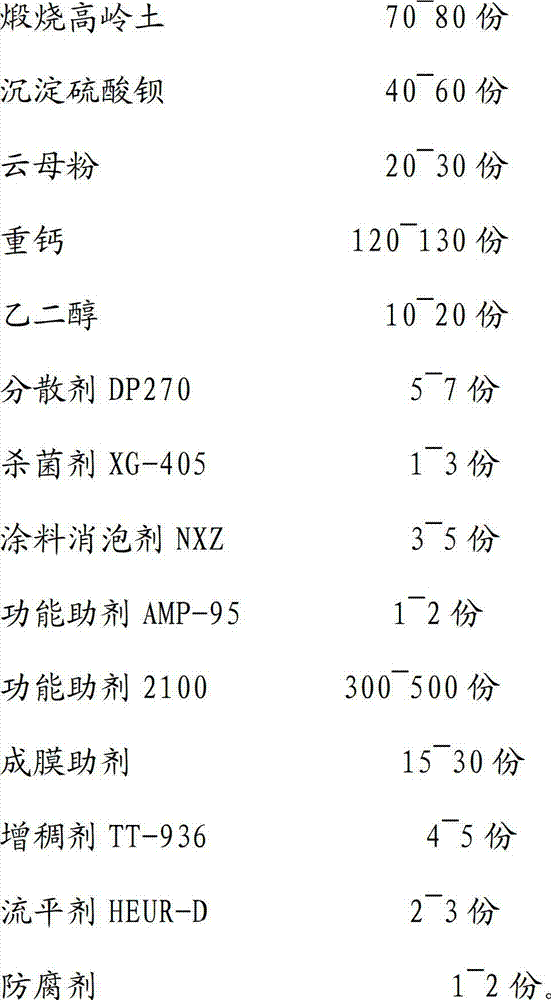

[0018] The core-shell silicone durable coating is made of the following raw materials in parts by weight:

[0019]

[0020]

[0021] The production method of the core-shell silicone durable coating is to add the above-mentioned parts by weight of water, cellulose, rutile, calcined kaolin, precipitated barium sulfate, mica powder, heavy calcium and ethylene glycol in a closed pressure vessel and use it at 70°C. Hydrothermal mixed nucleation, reaction time 60min, then add the dispersant DP270, fungicide XG-405, paint defoamer NXZ, functional additive AMP-95, functional additive 2100, Film-forming aids, thickener TT-936, leveling agent HEUR-D and preservatives are added to polymerize at the same time, evenly stirred, matured, and the viscosity is adjusted. After passing the technical index inspection, it is measured and packaged.

Embodiment 3

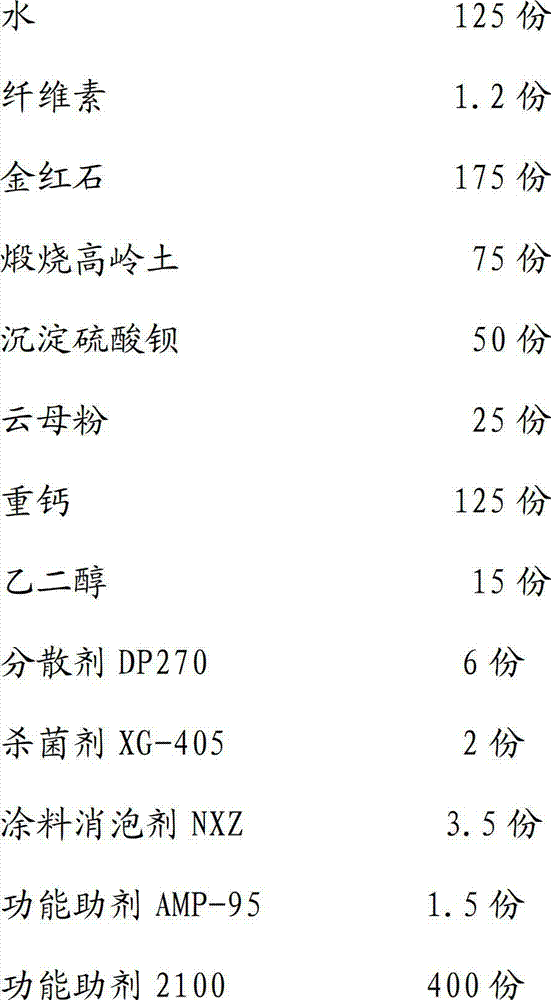

[0023]

[0024]

[0025] The production method of the core-shell silicone durable coating is to add the above-mentioned parts by weight of water, cellulose, rutile, calcined kaolin, precipitated barium sulfate, mica powder, heavy calcium and ethylene glycol in a closed pressure vessel and use it at 60°C. Hydrothermal mixed nucleation, reaction time 50min, then add the dispersant DP270, fungicide XG-405, paint defoamer NXZ, functional additive AMP-95, functional additive 2100, Film-forming aids, thickener TT-936, leveling agent HEUR-D and preservatives are added to polymerize at the same time, evenly stirred, matured, and the viscosity is adjusted. After passing the technical index inspection, it is measured and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com