Production technique for preparing 2,3-butanedione from 2,3-butanediol by one-step oxidization and heterogeneous catalyst used by same

A heterogeneous catalyst and production process technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, carbon-based compound preparation, etc., can solve the problems of expensive selenium dioxide, low yield, and failure to achieve large-scale industrialization. Achieve the effect of high yield and liquid time, low reaction temperature, and green source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

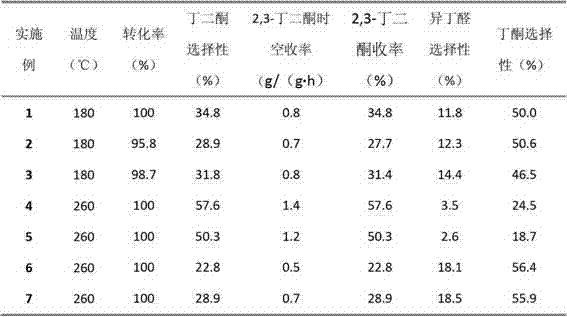

[0019] Embodiment 1: 0.5Mo / HZSM-5 (360) catalyst and reaction performance thereof

[0020] Mix HZSM-5 raw powder with a Si / Al ratio of 360, ammonium molybdate tetrahydrate and water in the following mass ratio: raw HZSM-5 powder: ammonium molybdate tetrahydrate: water=10:0.9:60. Immerse at room temperature for 24 hours under stirring conditions, dry at 110°C, and roast the solid material at 500°C to 550°C for 4 hours to obtain Mo 2 o 3 A 0.5Mo / HZSM-5(360) catalyst with a content (converted mass content) of 0.5wt%.

[0021] The catalyst prepared above is pressed into tablets, crushed and screened into 30-40 mesh particles, and used for one-step oxidation of 2,3-butanediol to prepare 2,3-butanedione. The reaction raw material is 60wt% 2,3-butanediol aqueous solution, and the liquid hourly space velocity is 2.4h -1 (calculated in butanediol), pure oxygen flow rate 8.3cm 3 / (g.min), the reaction temperature is 180°C, the conversion rate of 2,3-butanediol and the selectivity of...

Embodiment 2

[0022] Embodiment 2: 1.0Fe / HZSM-5 (120) and its reaction performance

[0023] Mix HZSM-5 raw powder with a Si / Al ratio of 120, ferric nitrate nonahydrate and water in the following mass ratio: HZSM-5 raw powder: ferric nitrate nonahydrate: water=10:0.5:40. Immerse at room temperature for 24 hours under stirring conditions, dry at 110°C, and roast the solid material at 500°C to 550°C for 4 hours to obtain Fe 2 o 3 A 1.0Fe / HZSM-5(120) catalyst with a content (converted mass) of 1.0wt%.

[0024] The catalyst prepared above is pressed into tablets, crushed and screened into 30-40 mesh particles, and used for one-step oxidation of 2,3-butanediol to prepare 2,3-butanedione. The reaction raw material is 60wt% 2,3-butanediol aqueous solution, and the liquid hourly space velocity is 2.4h -1 (calculated as butanediol), air velocity 12cm 3 / (g.min), the reaction temperature is 180°C, the conversion rate of 2,3-butanediol and the selectivity of main products are listed in Table 1.

Embodiment 3

[0025] Embodiment 3: 2.0Co / HZSM-5 (200) and its reaction performance

[0026] Mix HZSM-5 raw powder with a Si / Al ratio of 200, cobalt dichloride and water in the following mass ratio: HZSM-5 raw powder: cobalt dichloride: water=10:0.3:40. Immerse at room temperature for 24 hours under stirring conditions, dry at 110°C, and calcinate the obtained solid material at 500°C to 550°C for 4 hours to prepare a 2.0Co / HZSM-5(200) catalyst with a CoO content (converted mass) of 2.0wt%.

[0027] The catalyst prepared above is pressed into tablets, crushed and screened into 30-40 mesh particles, and used for one-step oxidation of 2,3-butanediol to prepare 2,3-butanedione. The reaction raw material is 60wt% 2,3-butanediol aqueous solution, and the liquid hourly space velocity is 2.4h -1 (calculated in butanediol), oxygen-argon gas mixture (oxygen content 50%) flow rate 12cm 3 / (g.min), the reaction temperature is 180°C, the conversion rate of 2,3-butanediol and the selectivity of main pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com