Glass fiber chopped strand mat, production method and core material for vacuum heat-insulation boards

A technology of vacuum insulation panel and glass fiber, which is applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, mechanical equipment, etc. , to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Novel glass fiber chopped strand mat of the present invention, wet preparation process is as follows:

[0023] (1) Put the preferred length 6mm, glass fiber chopped strands with a fiber diameter of 9 μm and thickener, dispersant, defoamer, into the beater for batching, and disperse by beating;

[0024] (2) Evenly arrange the slurry suitable for a certain quality on the filter screen of the single wire forming machine through the conveying equipment, and then carry out forced negative pressure dehydration and shaping to obtain wet continuous glass fiber chopped strand mat;

[0025] (3) Transport the wet continuous glass fiber chopped strand mat to an oven at 100-250°C for drying, and transport it to the cutting area for cutting to obtain a sheet-like core material meeting the size requirements;

[0026] (4) Stack the continuous glass fiber chopped strand mats of the same size neatly for later use.

[0027] Wherein, the molded core material mentioned in step (3) has a th...

Embodiment 2

[0029] The glass fiber chopped strand mat of the present invention is used as a core material of a vacuum insulation panel, and the preparation process of the vacuum insulation panel is as follows:

[0030] (1) The novel glass fiber chopped strand mat in Example 1 is placed in a heat treatment furnace and heated with a maximum temperature of 170°C;

[0031] (2) When the temperature rises to the set value of 170°C, keep it warm for 60 minutes, open the heat treatment furnace and take out the new glass fiber chopped strand mat;

[0032] (3) Pack the laminated glass fiber chopped strand mat into a high-barrier packaging bag according to the thickness requirements, and place the getter at a specific position;

[0033] (4) Putting the high-barrier packaging bag with glass fiber chopped strand mat into a pre-set vacuum sealing machine for sealing to obtain a vacuum insulation panel;

[0034] (5) Turn on the vacuum sealing machine and take out the vacuum insulation panel.

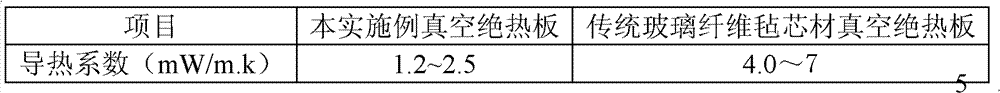

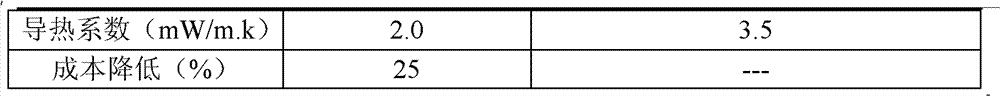

[0035] ...

Embodiment 3

[0041] Glass fiber chopped strand mat of the present invention, wet process is as follows:

[0042] (1) 50Kg of the alkali-free glass fiber chopped strands with a preferred length of 6mm and a fiber diameter of 9 μm and thickener (chemical name: hydroxypropyl methylcellulose) 1.2Kg, dispersant (chemical name: fatty alcohol poly Oxyethylene ether silane) 1.2Kg, defoamer (organopolysiloxane mixture) 5g, other additives (preservatives: chlorothalonil or sodium nitrite) 4g are batched according to mass ratio and put into the beater for beating dispersion;

[0043] (2) The slurry with a concentration of 0.5‰ is evenly arranged on the filter screen of the single wire forming machine through the conveying equipment, and then the wet continuous glass fiber chopped strand mat is obtained after forced negative pressure dehydration and setting;

[0044] (3) Transport the wet continuous glass fiber chopped strand mat to an oven at 50-180° C. for drying, and transport it to the cutting ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com