Collagen-g-polymer/Ag multi-hole nano antibacterial film material and preparation method thereof

A collagen, film material technology, applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellants, etc., to achieve the effect of good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

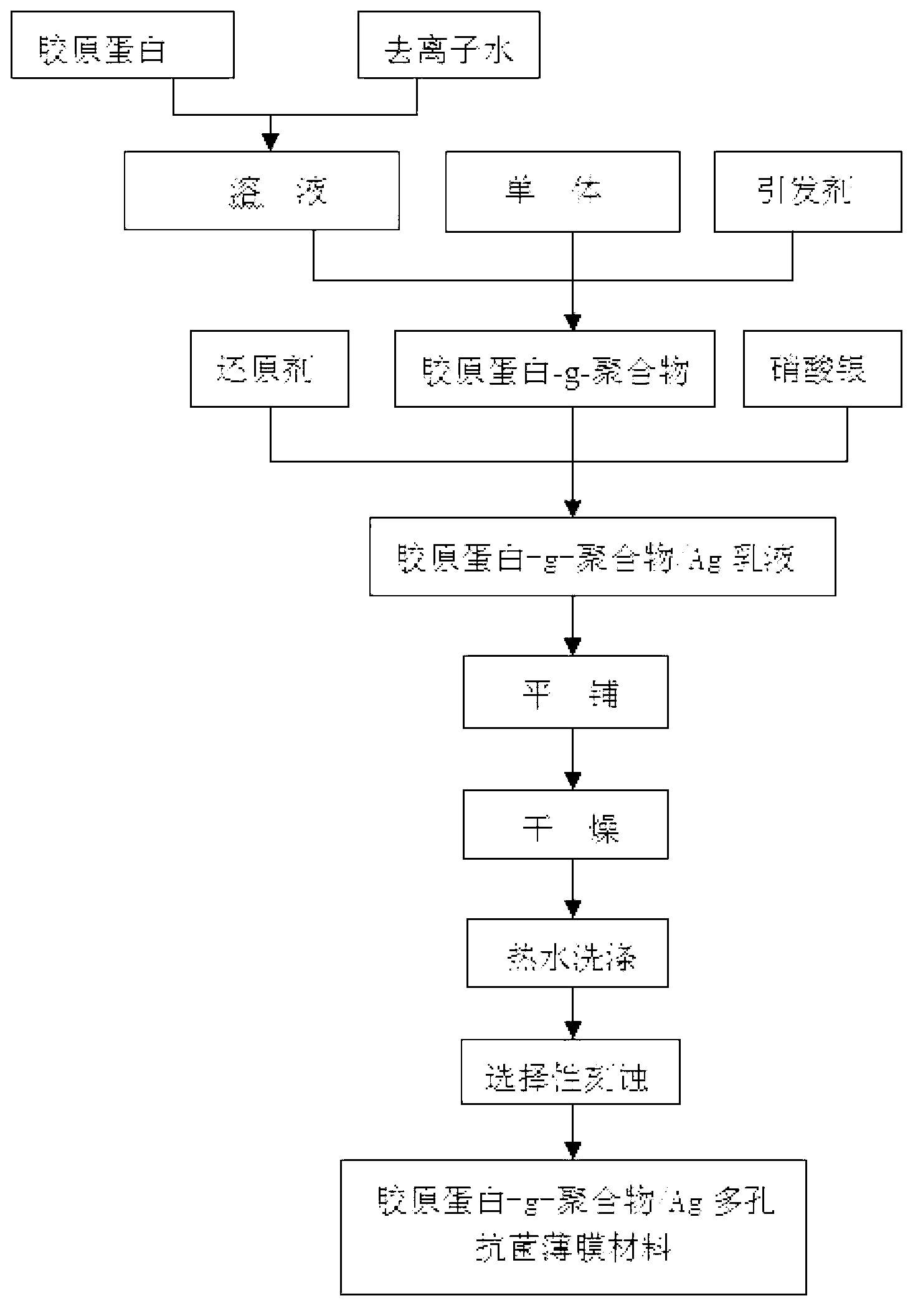

Method used

Image

Examples

Embodiment 1

[0027] Step 1, dissolve 4G collagen (beyond) at 96 ml 40 ~ 60 o C in hot water;

[0028] Step 2, add 0.2g styrene monomer to step 1, pass n 2 It

[0029] Step 3, add 0.002g potassium sulfate cause, 60 o C reaction 3hh;

[0030] Step 4, add 4ml 1g / L nitrate solution to step 3 mixing solution,

[0031] Step 5, add sodium sodium reducing agent to step 4 solution;

[0032] Step 6, cool to room temperature, diffuse and solidify it on the slide of the slice;

[0033] Step 7: Use hot water to remove unacceptable collagen and residual potassium sulfate causes in the film;

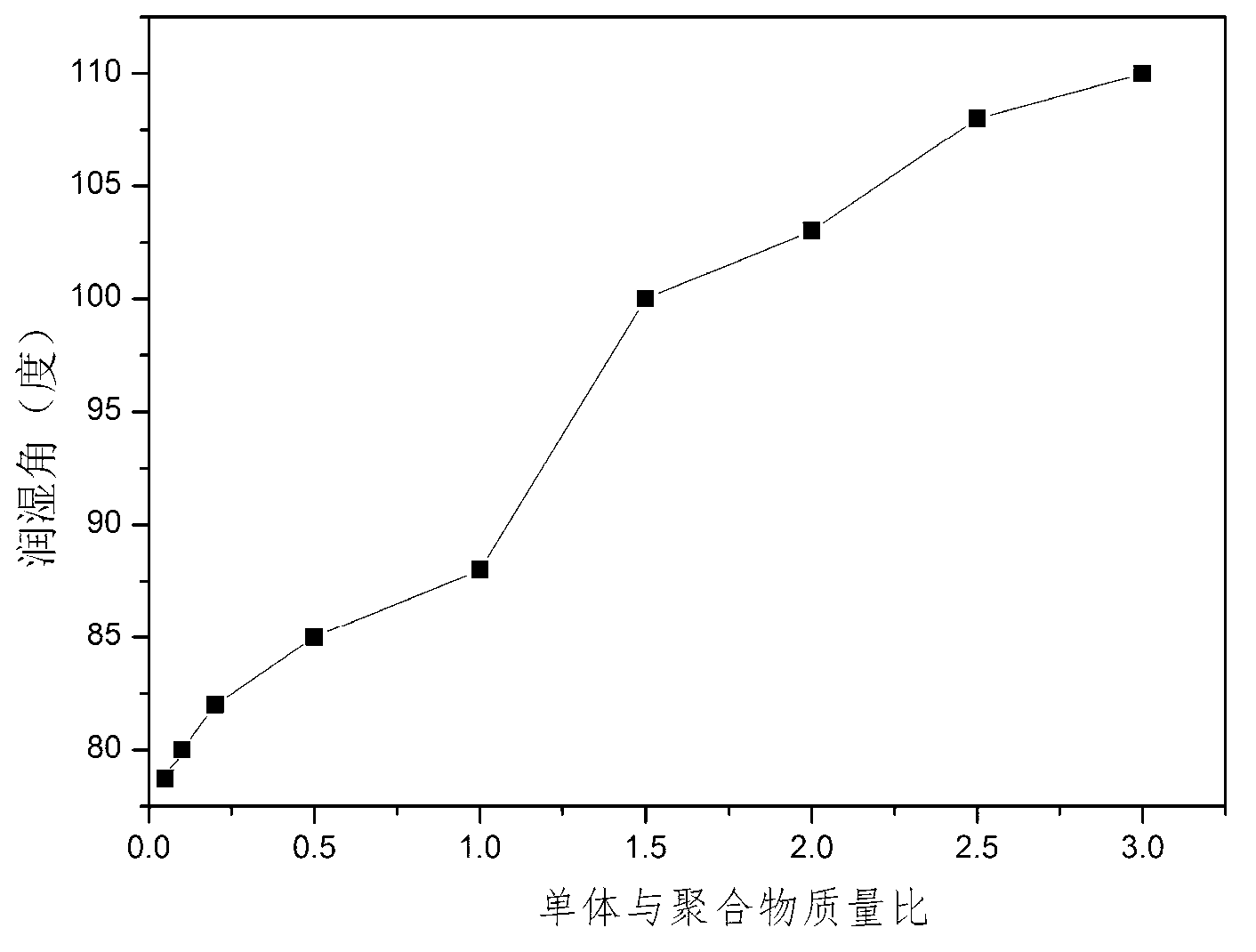

[0034] Step 8. Place the film 7 in the Thor's extractor, and use acetone solvents to etch the by-products polystyrene microbolis, that is, the porous collagen -g-polymer / AG antibacterial film material, collagen and branches.The rate is 4%, and the wet angle is 76 o The size of AG nanoparticles is 3 ~ 6m.

Embodiment 2

[0036] Step 1, dissolve 1g collagen to 99 ml 40 ~ 60 o C in hot water;

[0037] Step 2, add 1g of ethyl acetate monomer to step 1, pass n 2 It

[0038] Step 3, add 0.01g hydrogen peroxide solution (50%) to step 2 mixing solution as a cause, 80 o C reaction 1h;

[0039] Step 4, add 5ml 1g / L nitrate solution to step 3 mixing solution;

[0040] Step 5: Add potassium borohydride to the solution to the solution 4;

[0041] Step 6, cool to room temperature, diffuse and solidify it on the slide of the slice;

[0042] Step 7, remove unacceptable collagen in the film with hot water;

[0043] Step 8. Place the film 7 in the Thor's extractor, and use acetone solvents to etch by-products polyacin acetate micro-ball, that is, the porous collagen -g-polymer / AG antibacterial film material, collagen connectionThe branch rate is 42%, and the wet angle is 88 o The size of AG nanoparticles is 3 ~ 6m.

Embodiment 3

[0045] Step 1, dissolve 1g collagen to 99ml 40 ~ 60 o C in hot water;

[0046] Step 2, add 0.2g of ethyl chloride monomer to step 1, pass n 2 It

[0047] Step 3, add 0.001g dihydroxyl iodotic acid combined copper potassium in the mixing solution to step 2 as a cause, 100 o C reaction 1h;

[0048] Step 4. Add 1g / L nitrate solution to step 3 mixing solution;

[0049] Step 5: Add aquatic reducing agent to step 4 solution;

[0050] Step 6, cool to room temperature, diffuse and solidify it on the slide of the slice;

[0051] Step 7: Use hot water to remove unacceptable collagen in the film and dihydroxyl iodotic acid combined copper potassium cause;

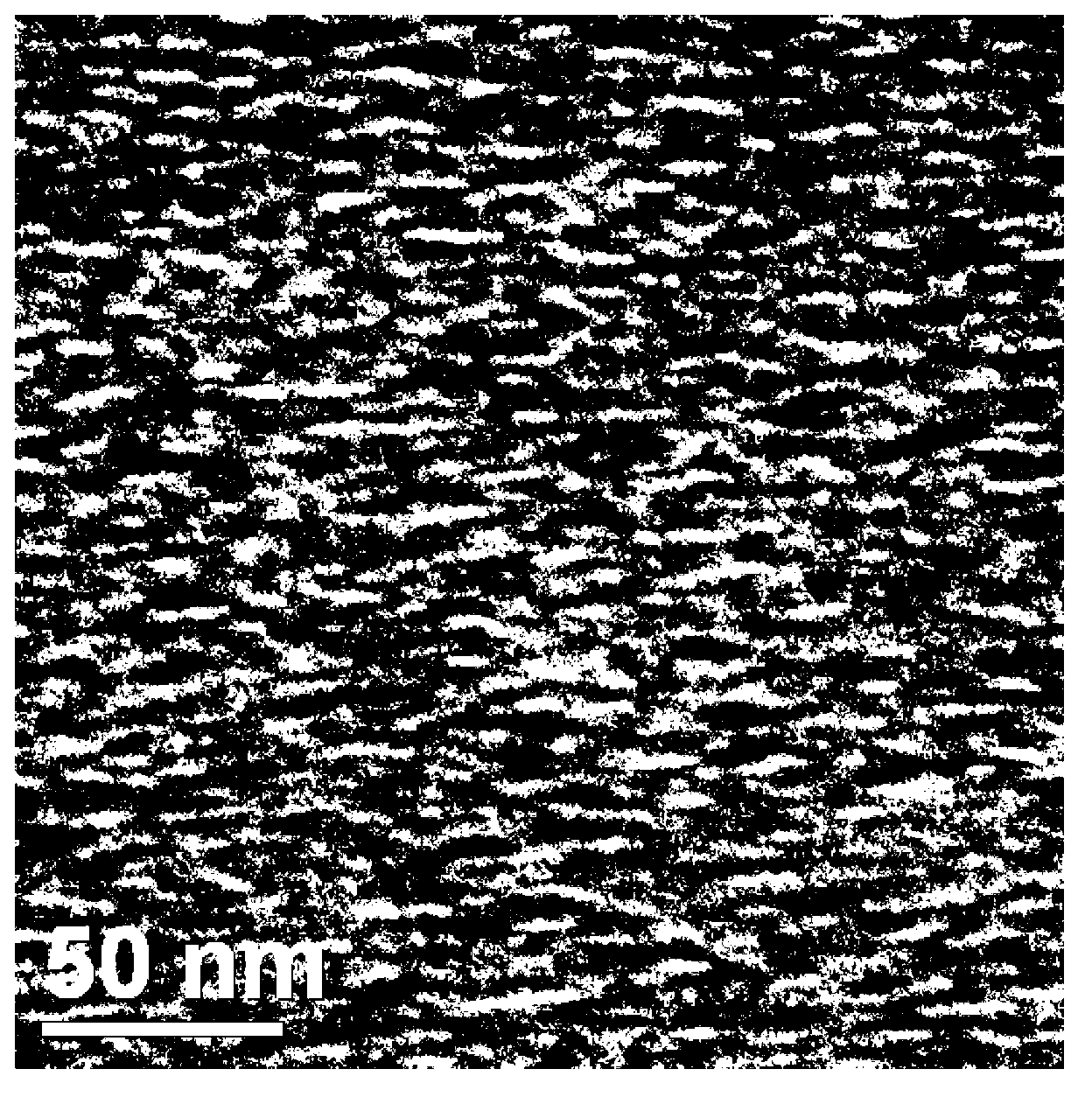

[0052] Step 8. Place the film 7 in a thin film in the Soe extract, and erode the by-product polyvinyl chloride microspheres with chlorine solvents, that is, the porous collagen -g-polymer / AG antibacterial film material, collagen and branches.The rate is 15%, and the wet angle is 82 o The size of AG nanoparticles is 3 ~ 6m, and its FR-SEM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com