Welding shaping method for foamed aluminium board

A foamed aluminum plate, welding forming technology, applied in the field of aluminum plate welding, can solve the problems of high cost, complicated process, low production efficiency of large-sized foamed aluminum, etc., achieve good mechanical properties and corrosion resistance, and increase the effect of the bonding interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

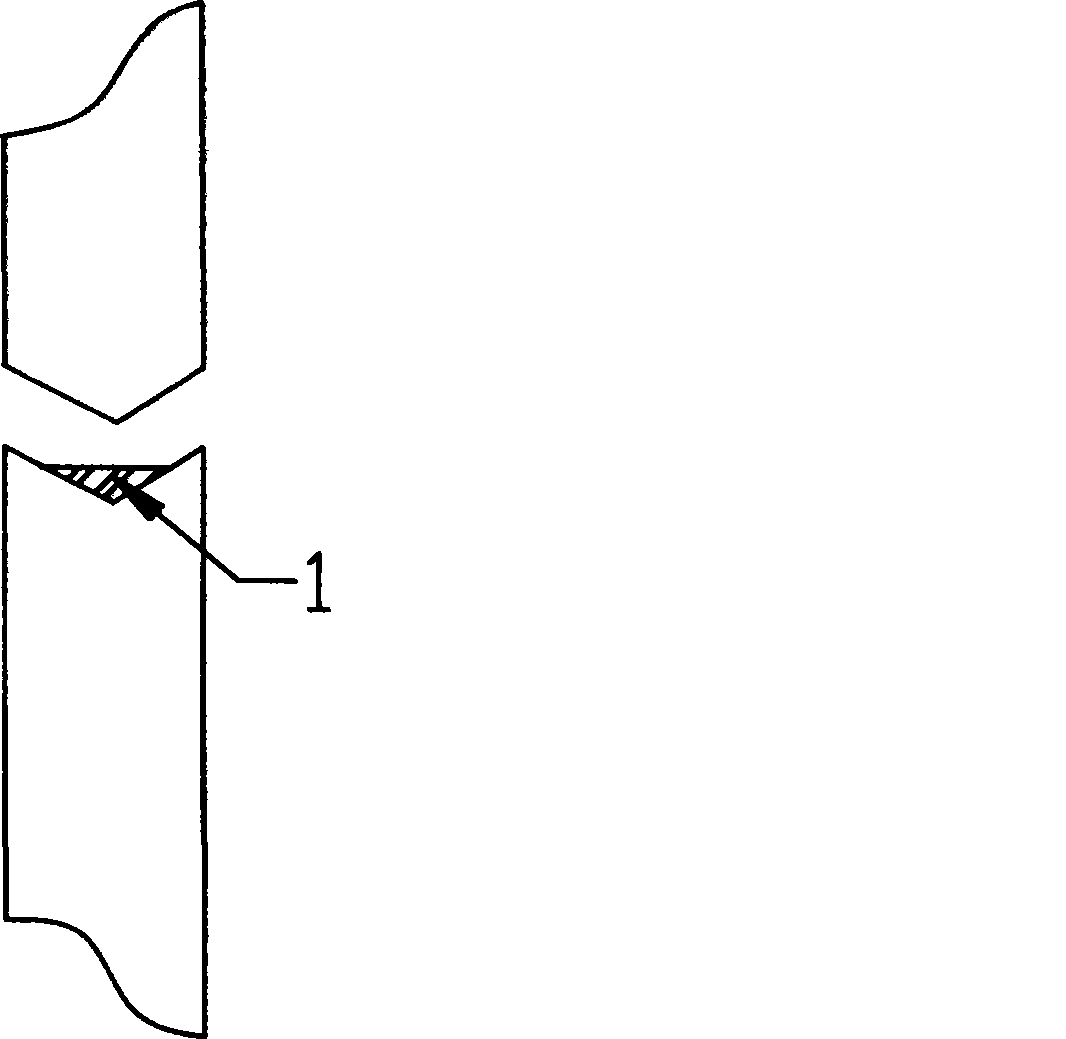

Embodiment 1

[0027] The first step: use wire cutting to process the aluminum foam board into regular cubes or cuboids of uniform size. Add 2 to 5% volume ratio of detergent in clean water to clean the processed foamed aluminum plate, then rinse it with clean water and dry it. Use an electric band saw to make a V-shaped bevel on the aluminum foam board. It is required that the opposite sides be convex V-shaped and the other side be concave V-shaped. Derust and degrease the groove of the foamed aluminum plate to be welded. The basic process is to place the main body of the groove of the foamed aluminum to be welded in a 5-8% NaOH solution at 55-65°C for 7 minutes, and then take it out and completely wash it with hot water. After washing, put the concentration of about 30 ~ 40% HNO 3 The solution was neutralized for about 1.5 minutes, then washed with water, dried with acetone, and finally dried in an oven at 130°C for later use. The concentration of NaOH solution can be 5%, 6%, 8%, the tem...

Embodiment 2

[0033] The first step: use wire cutting to process the aluminum foam board into a cube with a side length of 150mm and a thickness of 20mm. Add 2% volume ratio of detergent to clean water to clean the processed square aluminum foam board, then rinse it with clean water and dry it. Use an electric band saw to make a V-shaped bevel on the aluminum foam board. It is required that the opposite sides be convex V-shaped and the other side be concave V-shaped. Derust and degrease the groove of the foamed aluminum plate to be welded. The basic process is to first place the body of the foamed aluminum groove to be welded in a 5% NaOH solution at about 60°C for 7 minutes, take it out and rinse it with hot water before putting it in place. The input concentration is about 30% HNO 3 The solution was neutralized for about 1.5 minutes, then washed with water, dried with acetone, and finally dried in an oven at 130°C for later use.

[0034] The second step: chemically pure ZnCl 2 Add wate...

Embodiment 3

[0039] The first step: use wire cutting to process two foamed aluminum plates with different hole diameters into cubes with a side length of 180mm and a thickness of 30mm. Add 3.5% volume ratio of detergent into clean water to clean the processed square aluminum foam board, then rinse it with clean water and dry it. Use an electric band saw to make a V-shaped bevel on the aluminum foam board. It is required that the opposite sides be convex V-shaped and the other side be concave V-shaped. Derust and degrease the groove of the foamed aluminum plate to be welded. The basic process is to place the body of the foamed aluminum groove to be welded in a 6% NaOH solution at about 60°C for 7 minutes, take it out and rinse it completely with hot water, and then put it away. The input concentration is about 35% HNO 3 The solution was neutralized for about 1.5 minutes, then washed with water, dried with acetone, and finally dried in an oven at 130°C for later use.

[0040] The second st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com