Sealant with good wettability for electronic equipment and preparation method of the sealant

A technology of electronic equipment and wettability, which is applied in the field of sealants, can solve the problems such as the wettability of sealants that have not been raised, and achieve the effects of avoiding coating difficulties, effectively controlling the viscosity of the system, and improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

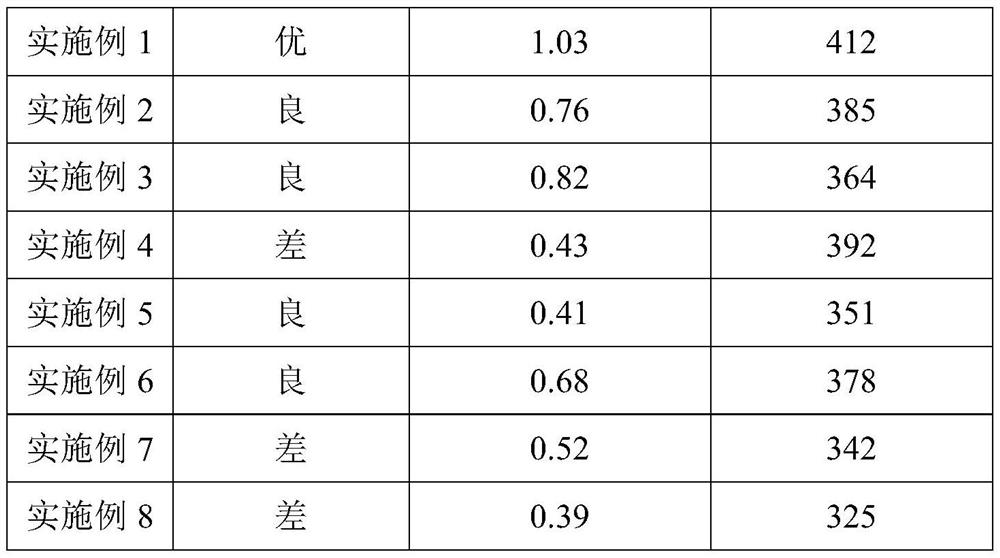

Examples

preparation example Construction

[0042] A second aspect of the present invention provides a method for preparing a sealant with good wettability for electronic equipment, comprising the following steps:

[0043] Add polymer resin, fillers, additives, and acrylic ester compounds into a mixer and mix and stir at a stirring speed of 600-1500 rpm for 30-90 minutes to obtain the product.

Embodiment 1

[0048] A sealant with good wettability for electronic equipment. The raw materials are prepared in parts by weight, including: 100 parts of hydroxyl-terminated polydimethylsiloxane, 8 parts of filler, 3.5 parts of auxiliary agent, and 3 parts of methyl methacrylate .

[0049] Hydroxyl-terminated polydimethylsiloxane with a viscosity of 30,000cs at 25°C was purchased from Wuxi Ruiheer Environmental Protection Technology Co., Ltd.

[0050] The filler is fumed white carbon black and mica powder; the weight ratio of fumed white carbon black and mica powder is 1:0.6.

[0051] Fumed silica, with a particle size of 15-30nm, was purchased from Zhejiang Jiupeng New Material Co., Ltd.; mica powder was purchased from Lingshou County Baofeng Mica Processing Co., Ltd.

[0052] The auxiliary agents are 3 parts of silane coupling agent and 0.5 part of benzoyl peroxide.

[0053] The silane coupling agent is 3-glycidyloxypropyltrimethoxysilane and γ-methacryloxypropyltrimethoxysilane in a weig...

Embodiment 2

[0057] A sealant with good wettability for electronic equipment. The raw materials are prepared in parts by weight, including: 100 parts of hydroxyl-terminated polydimethylsiloxane, 6 parts of filler, 3.5 parts of auxiliary agent, and 3 parts of methyl methacrylate .

[0058] Its specific implementation method is the same as Example 1, and the difference with Example 1 is 3 parts of fumed white carbon black.

[0059] For a preparation method of a sealant with good wettability for electronic equipment, refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com