Sn-Cu-Ni lead-free solder containing Ga and Nd

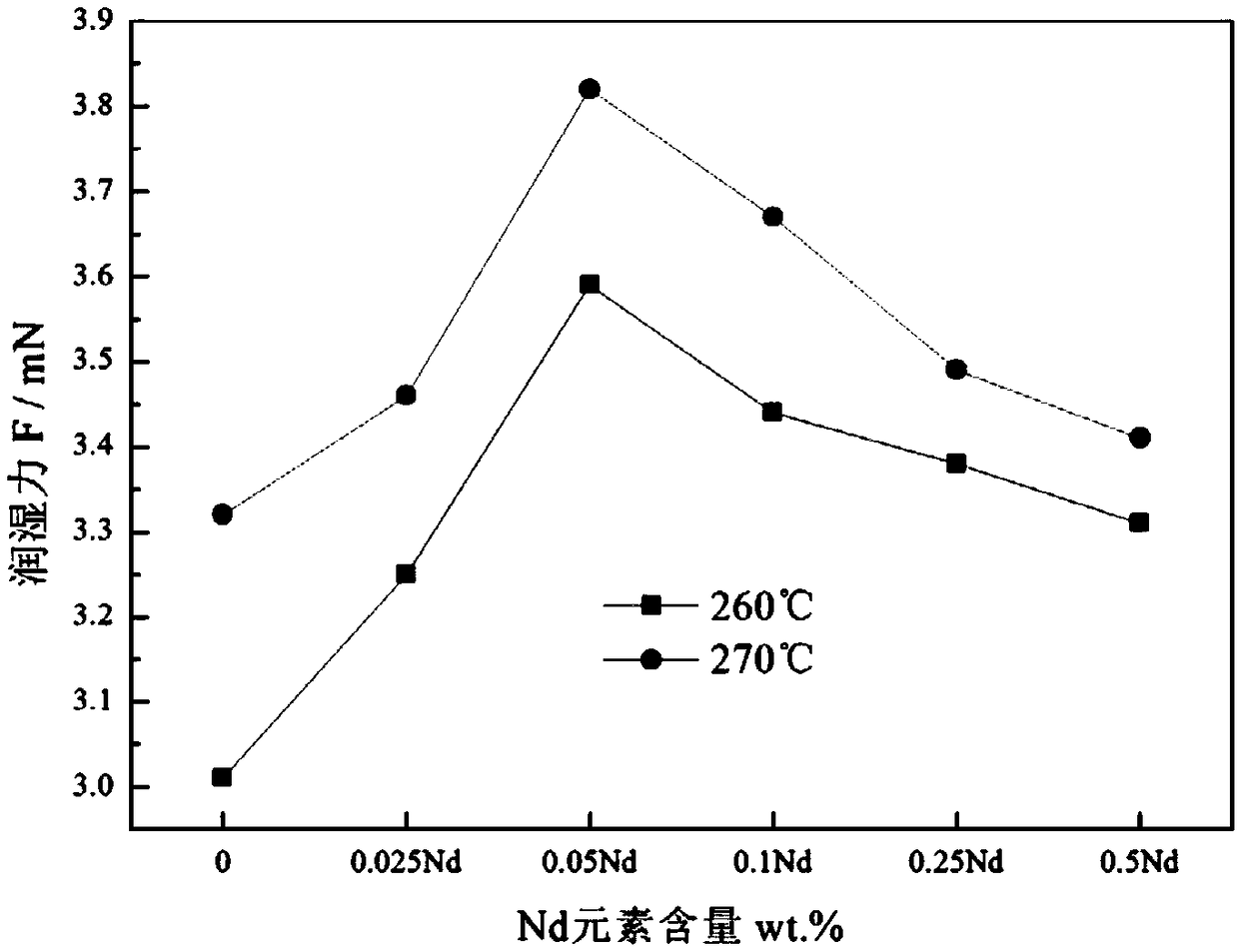

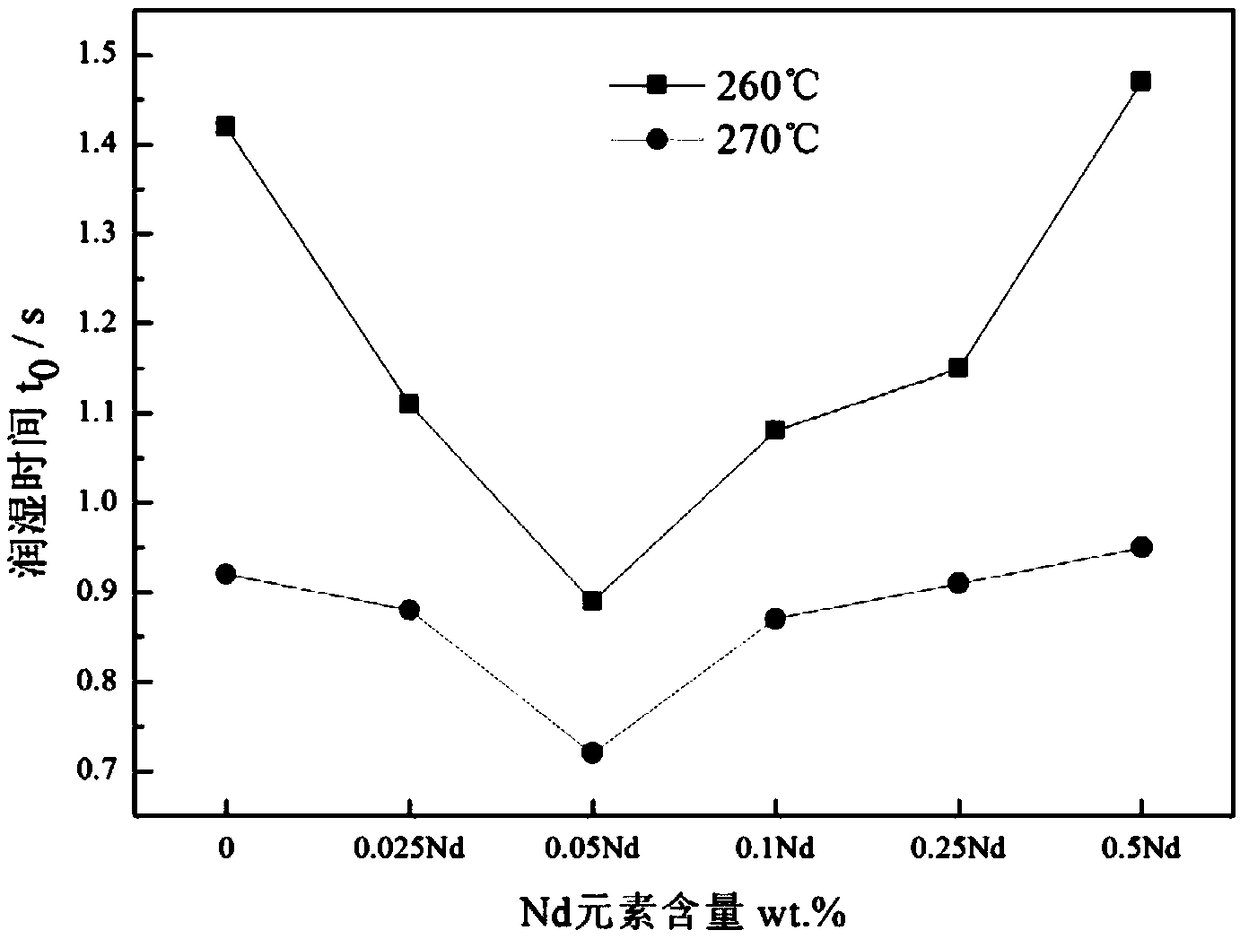

A sn-cu-ni, lead-free solder technology, applied in the direction of welding/cutting media/materials, metal processing equipment, welding equipment, etc., can solve the problems of short circuit of electronic components and reduce the reliability of brazed joints, etc. Achieve the effect of uniform structure, inhibiting the growth of tin whiskers, and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Sn-Cu-Ni lead-free solder containing Ga and Nd, including: 0.45% Cu, 0.5% Ni, 0.003% As, 0.020% Sb, 0.4% Ga, 0.04% Nd by mass percentage , the balance being Sn. The mass ratio of Ga and Nd satisfies Ga:Nd=10:1.

[0028] The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Ga and Nd" obtained by the above-mentioned composition ratio is about 210°C, and the liquidus temperature is about 218°C (both taking into account experimental errors). Cooperating with commercially available RMA brazing flux, it has excellent wetting performance on the copper plate, and the tensile strength of the brazing seam reaches 45MPa±5MPa.

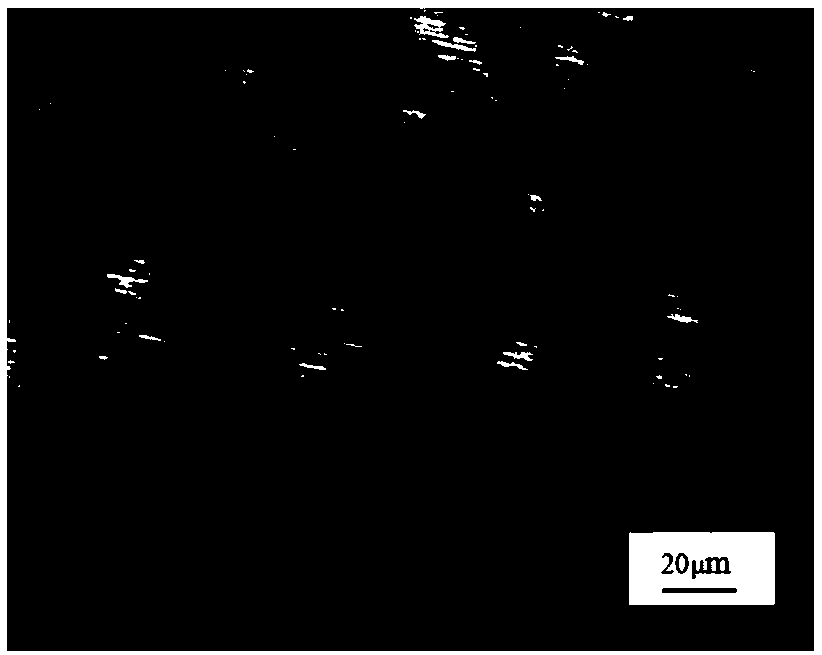

[0029] image 3 It shows that after aging for 720 hours (30 days), there is no obvious change in the intermetallic compound at the interface of the Sn-Cu-Ni lead-free solder brazing seam containing Ga and Nd, and there is no tin whisker initiation, indicating that the solder joint (brazing seam) is reliable. performance has been significant...

Embodiment 2

[0031] Sn-Cu-Ni lead-free solder containing Ga and Nd, including: 1.1% Cu, 0.05% Ni, 0.008% As, 0.014% Sb, 0.6% Ga, 0.06% Nd by mass percentage , the balance being Sn. The mass ratio of Ga and Nd satisfies Ga:Nd=10:1.

[0032] The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Ga and Nd" obtained by the above-mentioned composition ratio is about 210°C, and the liquidus temperature is about 218°C (both taking into account experimental errors). Cooperating with commercially available RMA brazing flux, it has excellent wetting performance on the copper plate, and the tensile strength of the brazing seam reaches 45MPa±5MPa.

[0033] image 3 It shows that after aging for 720 hours (30 days), there is no obvious change in the intermetallic compound at the interface of the Sn-Cu-Ni lead-free solder brazing seam containing Ga and Nd, and there is no tin whisker initiation, indicating that the solder joint (brazing seam) is reliable. performance has been significa...

Embodiment 3

[0035] Sn-Cu-Ni lead-free solder containing Ga and Nd, including: 0.7% Cu, 0.15% Ni, 0.005% As, 0.016% Sb, 0.5% Ga, 0.05% Nd by mass percentage , the balance being Sn. The mass ratio of Ga and Nd satisfies Ga:Nd=10:1.

[0036] The solidus temperature of the "Sn-Cu-Ni lead-free solder containing Ga and Nd" obtained by the above-mentioned composition ratio is about 210°C, and the liquidus temperature is about 218°C (both taking into account experimental errors). Cooperating with commercially available RMA brazing flux, it has excellent wetting performance on the copper plate, and the tensile strength of the brazing seam reaches 45MPa±5MPa.

[0037] image 3 It shows that after aging for 720 hours (30 days), there is no obvious change in the intermetallic compound at the interface of the Sn-Cu-Ni lead-free solder brazing seam containing Ga and Nd, and there is no tin whisker initiation, indicating that the solder joint (brazing seam) is reliable. performance has been significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com