Water-base correction fluid composition and preparation method thereof

A technology of composition and correction fluid, applied in the direction of coating, etc., can solve problems such as difficulty in painting, unsatisfactory performance of correction fluid, leaving brush marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing a water-based correction fluid composition, the method comprising: adding a film-forming polymer, an opaque polymer emulsion, a white pigment, and an optional defoamer to a mixed solution of water and a dispersant , Bactericide and antifungal agent and surfactant, after mixing evenly, disperse and grind to obtain water-based correction fluid.

[0028] The present invention has the following main advantages:

[0029] (1) The correction fluid composition of the present invention uses water as the main solvent, thus overcoming the environmental pollution problem caused by correction fluids based on volatile organic solvents in the prior art.

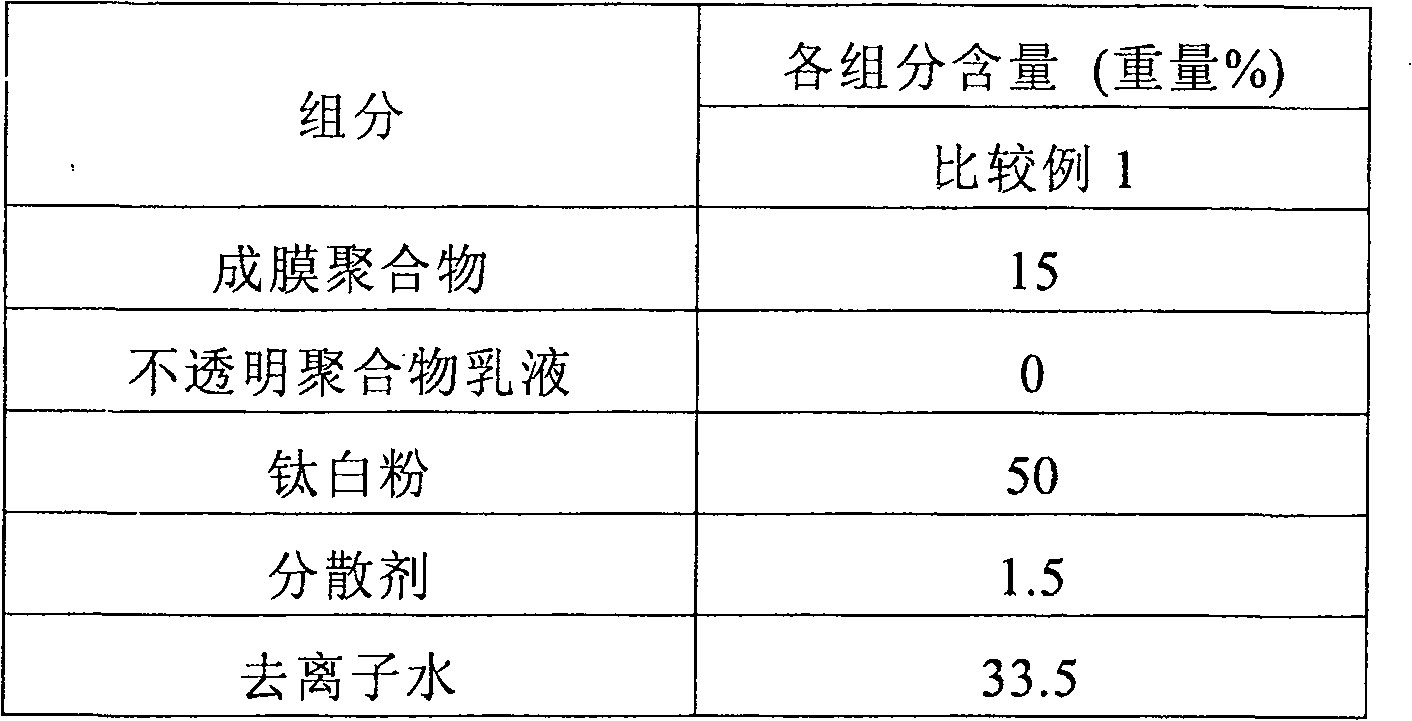

[0030] (2) The correction fluid composition of the present invention adopts an opaque polymer emulsion to partially replace the white pigment (usually titanium dioxide), thereby greatly reducing the cost of raw materials. Considering the ease of consumption of correction flu...

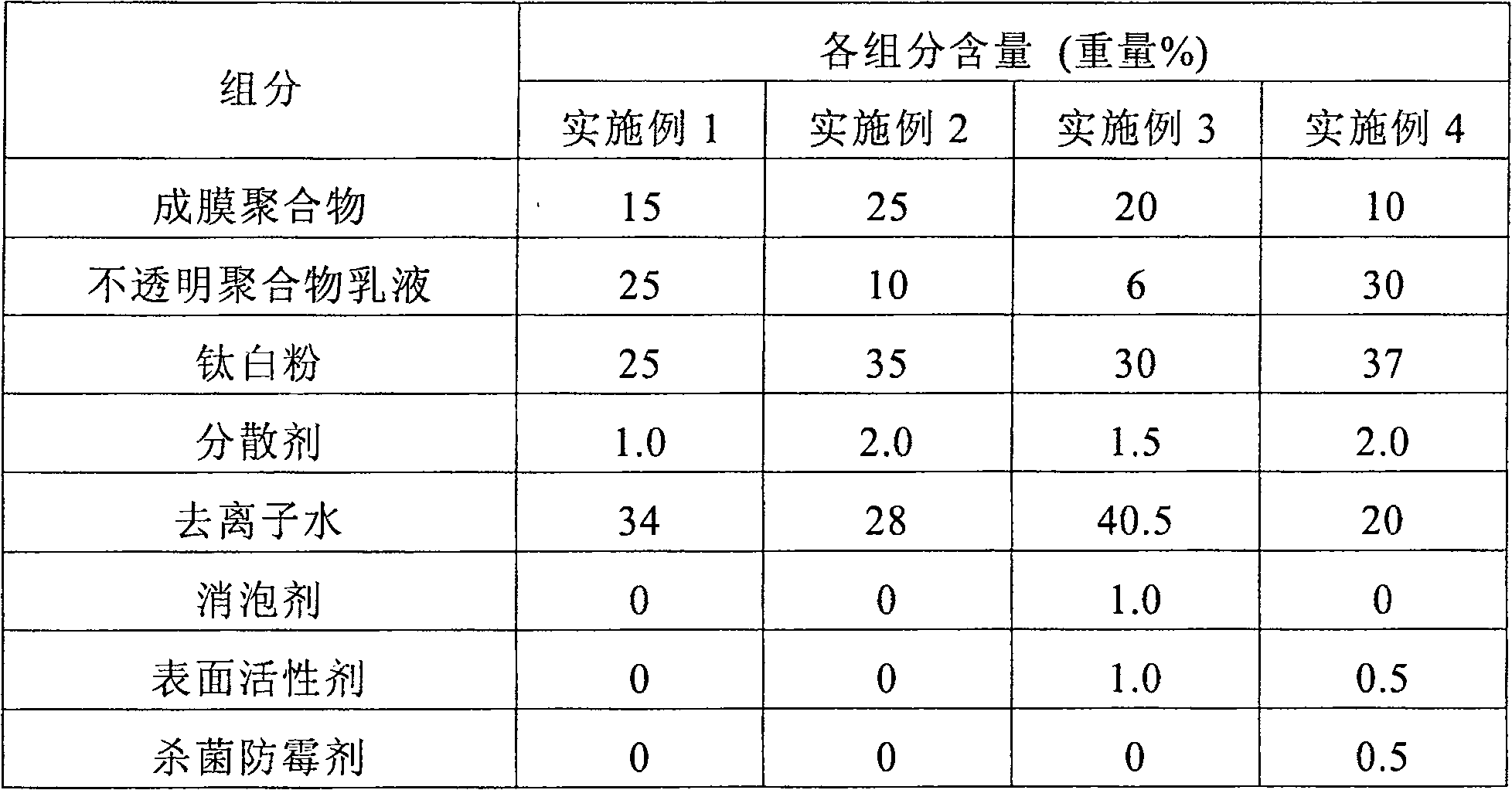

Embodiment 1

[0034] At normal temperature, add deionized water and polyacrylic acid sodium salt (purchased from Deqian Chemical Co., Ltd. as the product of DP-512) as a dispersant to a reactor with a stirrer. After mixing evenly, stir while stirring. Slowly add the following components: acrylic copolymer emulsion (purchased from Rohm and Haas Company as PRIMAL TM AC-268), a styrene-acrylic copolymer emulsion as an opaque polymer emulsion (available from The Dow Chemical Company as 98), titanium dioxide (purchased from DuPont's model is the product of Ti-Pure R-902), uniformly mixed, then dispersed by a high-speed disperser, and finally bead milled until the particle size of the dispersed particles in the dispersion is less than 50 μm, thus obtaining a water-based correction fluid composition. Each component and its amount are listed in Table 1.

Embodiment 2

[0036] At normal temperature, add deionized water and polyacrylic acid ammonium salt (purchased from Deqian Chemical Co., Ltd. as the product of DP-518) as a dispersant to a reactor with a stirrer. After mixing evenly, slowly stir while stirring. Add the following components: styrene-acrylic acid copolymer (available from UCB company's model VN937 product) as a film-forming polymer, styrene-acrylic acid copolymer emulsion (available from Dow Chemical Company) as an opaque polymer emulsion The model is 98), titanium dioxide (purchased from DuPont's model is the product of Ti-Pure R-902), uniformly mixed, then dispersed by a high-speed disperser, and finally bead milled until the particle size of the dispersed particles in the dispersion is less than 50 μm, thus obtaining a water-based correction fluid composition. Each component and its amount are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com