Waste water treatment system of ultraviolet light and ozone micro/nanobubbles and method

A wastewater treatment system and technology of micro-nano bubbles, applied in the application field, can solve the problems of poor biodegradability of acrylic wastewater, expensive membrane separation technology investment, unsatisfactory wastewater treatment, etc., to improve the biodegradability of wastewater, the number of bubbles, and improve Effect of Ozone Use Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

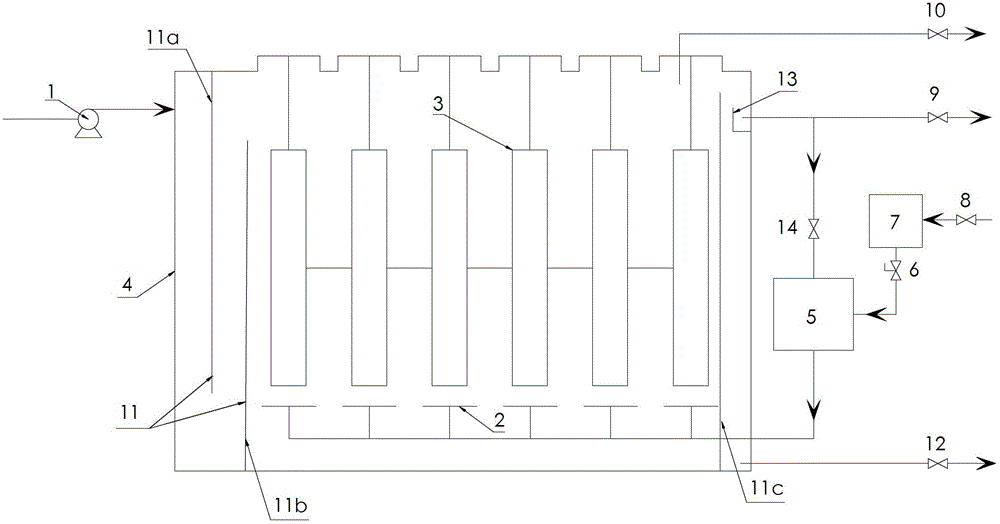

Image

Examples

specific Embodiment 1

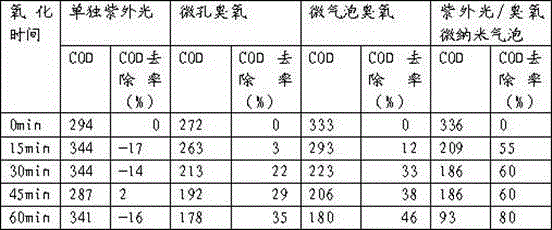

[0068] The waste water treatment system in this example treats acrylic fiber wastewater after hydrolytic acidification, pure oxygen aeration, and contact oxidation process, wherein the initial COD of acrylic fiber wastewater is about 1500 mg / L, and the biochemical The COD of the effluent is about 350mg / L, which does not meet the discharge requirements. In this embodiment, the biochemical effluent of the acrylic fiber wastewater is used as the raw wastewater for treatment. Among them, the power of the ultraviolet lamp tube in the ultraviolet lamp casing group (3) is 23W, the rated ozone output of the ozone generator is 2.5g / h, and the ozone flow rate and the water volume of the micronano bubble generator can be adjusted.

[0069] Table 1 shows the implementation effect of using ultraviolet light in conjunction with ozone micro-nano bubbles to treat the biochemical effluent of acrylic fiber wastewater, and compares the treatment effects of using ultraviolet and ozone processes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com