Germanium-base substrate surface passivation method

A substrate surface and substrate technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of reducing the interface state and cannot effectively suppress the diffusion and thinning of germanium surface atoms, so as to reduce the interface state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

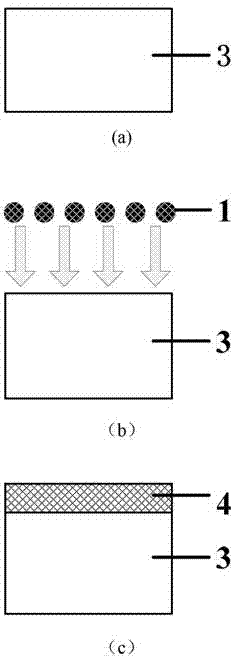

[0021] The method of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings and the germanium substrate.

[0022] 1) Clean the germanium substrate and remove the surface oxide layer, such as image 3 as shown in (a);

[0023] 2) Put the cleaned germanium substrate into the inductively coupled plasma chamber, use the reactive gas to generate plasma and process the germanium sheet in a plasma bath, and apply RIE power while the plasma bath is being processed.

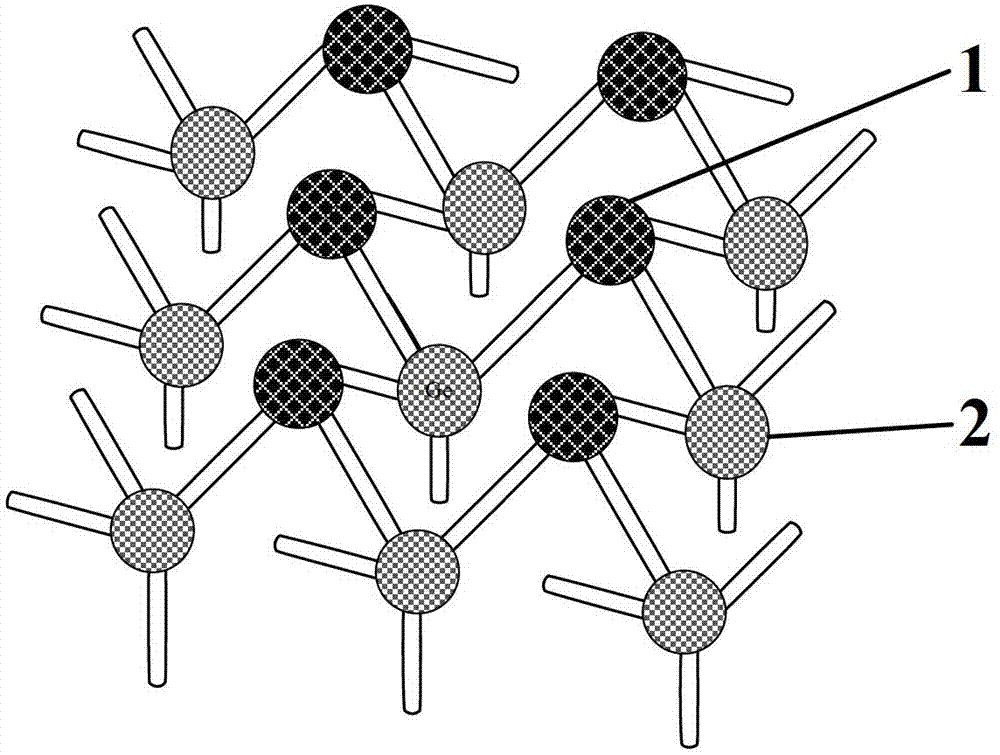

[0024] The reaction gas can be an elemental gas corresponding to a multibond atom and / or a hydride containing a multibond atom, or one or more gases and inert gas in the elemental gas corresponding to a multibond atom and a hydride containing a multibond atom Mixed gas of atomic gas (such as Ar gas). This embodiment preferably uses N 2 Mix gas with Ar to generate nitrogen plasma, and conduct plasma bath treatment on germanium substrates, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com