Silicon-germanium heterojunction solar cell and preparation method thereof

A silicon-germanium heterojunction and solar cell technology, which is applied in the field of solar cells, can solve problems such as defects, carrier recombination, and expensive equipment, and achieve the effects of reducing interface states, increasing short-circuit current, and fully utilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

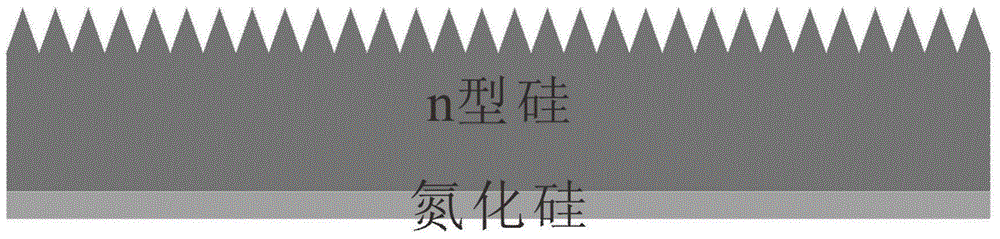

[0048] The silicon-germanium heterojunction solar cell provided in this embodiment, the structure of the silicon-germanium heterojunction solar cell includes from top to bottom: a silver electrode, an aluminum-doped zinc oxide AZO conductive layer, an n-type single crystal silicon wafer, an i-type SiGe alloy buffer layer thin film, p-type Ge thin film and gold electrode, the silicon germanium heterojunction solar cell has a wide spectral response value of 300-1800nm.

[0049] Wherein the aluminum-doped zinc oxide AZO conductive layer has a thickness of 100nm, the i-type SiGe alloy buffer layer film has a thickness of 150nm, and the p-type Ge film has a thickness of 200nm.

[0050] The silicon-germanium heterojunction solar cell is prepared by a method comprising the following steps:

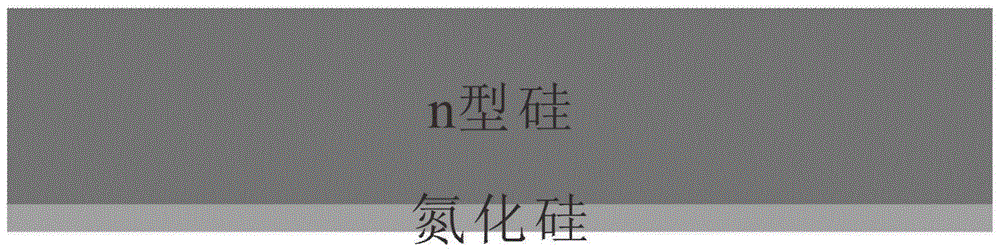

[0051] (1) Select an n-type single crystal silicon wafer polished on one side, and deposit Si on the polished surface by PECVD 3 N 4 Mask, the parameters of PECVD are: NH 3 and SiH 4 The flow...

Embodiment 2

[0070] The silicon-germanium heterojunction solar cell provided in this embodiment comprises, from top to bottom: a silver electrode, an AZO conductive layer, an n-type single crystal silicon wafer, an i-type SiGe alloy buffer layer film, a p-type Ge film and a gold electrode, The silicon germanium heterojunction solar cell has a wide spectral response value of 300-1800nm.

[0071] Wherein the thickness of the AZO conductive layer is 150nm, the thickness of the i-type SiGe alloy buffer layer film is 300nm, and the thickness of the p-type Ge film is 400nm.

[0072] Such as Figure 1-9 As shown, the silicon germanium heterojunction solar cell is prepared by a method comprising the following steps:

[0073] (1) Select n-type monocrystalline silicon wafers polished on one side, and prepare Si by PECVD 3 N 4 Mask, NH 3 and SiH 4 The flow ratio is 1:3.5, the substrate temperature is 285°C, the reaction pressure is 90Pa, the thickness is 70nm, and the deposition time is 90s;

...

Embodiment 3

[0083] The silicon-germanium heterojunction solar cell provided in this embodiment comprises, from top to bottom: a silver electrode, an AZO conductive layer, an n-type single crystal silicon wafer, an i-type SiGe alloy buffer layer film, a p-type Ge film and a gold electrode, The silicon germanium heterojunction solar cell has a wide spectral response value of 300-1800nm.

[0084] Wherein the thickness of the AZO conductive layer is 50nm, the thickness of the i-type SiGe alloy buffer layer film is 100nm, and the thickness of the p-type Ge film is 100nm.

[0085] Such as Figure 1-9 As shown, the silicon germanium heterojunction solar cell is prepared by a method comprising the following steps:

[0086] (1) Select n-type monocrystalline silicon wafers polished on one side, and prepare Si by PECVD 3 N 4 Mask, NH 3 and SiH 4 The flow ratio is 1:4.5, the substrate temperature is 315°C, the reaction pressure is 130Pa, the thickness is 80nm, and the deposition time is 105s;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com