Surface treatment method for copper foil, surface treated copper foil and copper foil for negative electrode collector of lithium ion secondary battery

A technology of surface treatment and copper foil, which is applied in the field of copper foil for negative electrode collectors, can solve the problems of increasing battery size and failing to meet long-term life, and achieves excellent adhesion and ultrasonic adhesion, and compatibility with active materials Excellent adhesion and ultrasonic adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

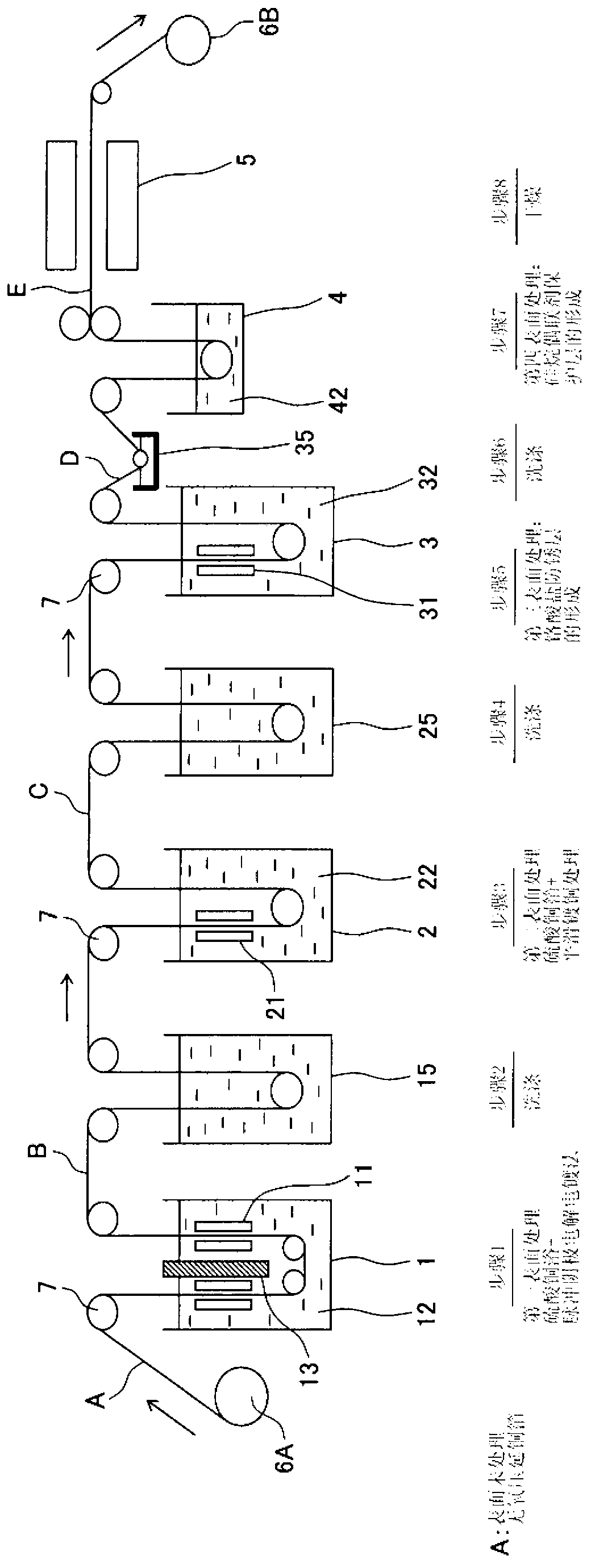

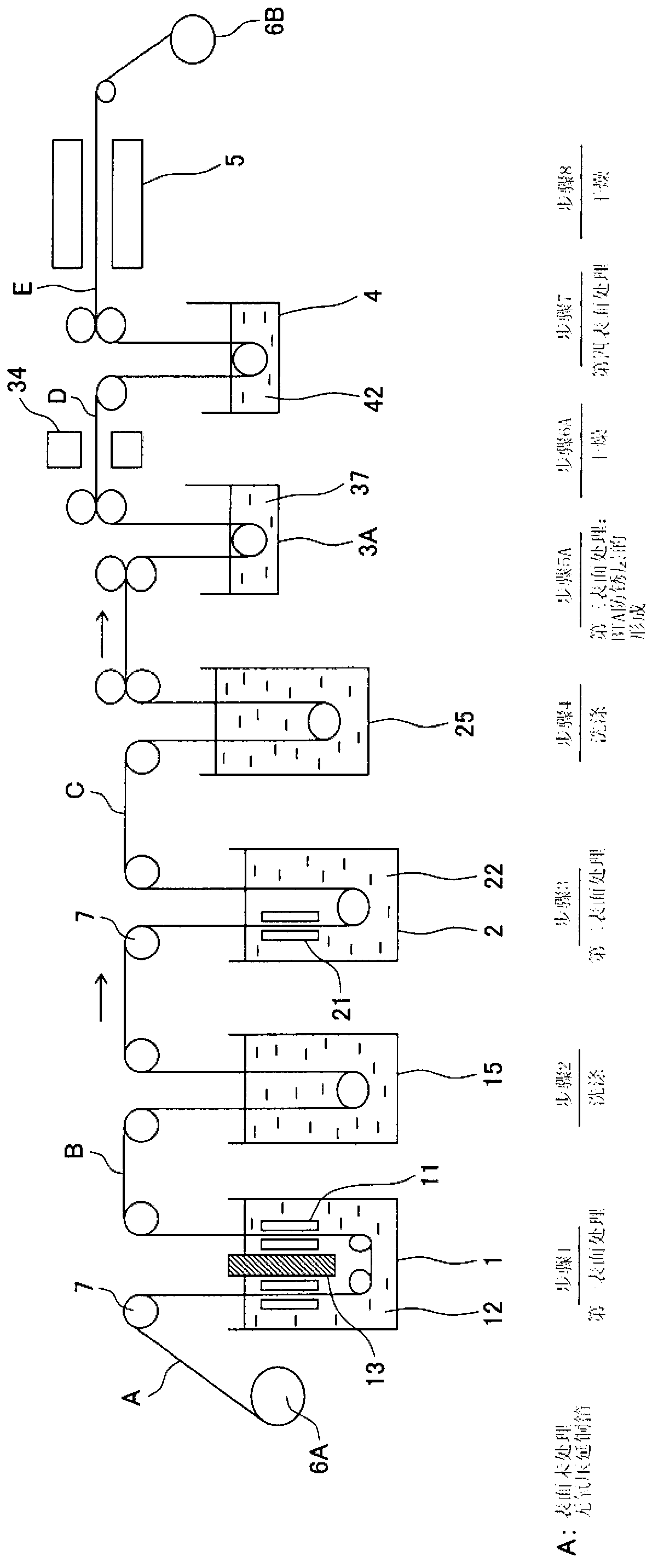

[0046] The surface treatment method of copper foil and the surface-treated copper foil according to the first embodiment of the present invention will be described.

[0047] Substrate

[0048] In the first embodiment of the present invention, the substrate to be subjected to surface treatment is made of copper (oxygen-free copper, Oxygen-free copper) that does not undergo surface treatment (hereinafter referred to as untreated) and does not contain oxygen. Rolled copper foil (hereinafter referred to as untreated oxygen-free rolled copper foil).

[0049] When the rolled copper foil made of oxygen-free copper is used, the ingot rolled into copper foil does not contain impurities, and the properties of the copper foil do not change, and there is no concern about brittleness in particular.

[0050] As a method of roughening the surface of the base material, for example, as a negative electrode current collector used in lithium-ion rechargeable batteries, in order to improve the...

specific example

[0117] For example, the conveying speed is set to 6-12 m / min, the flow rate of the copper-sulfuric acid electrolyte solution 12 (the first circulation laminar flow velocity) is set to 3-6 m / min, and the electrolysis treatment time is set to 2.5-5.0 seconds.

[0118] Copper-sulfuric acid electrolyte

[0119] As the copper-sulfuric acid electrolytic solution 12, for example, copper sulfate is 20 ~ 30g / L in terms of copper, and the concentration of sulfuric acid is expressed in H 2 SO 4 Calculation is 90~110g / L, sodium molybdate is 0.15~0.35g / L in terms of Mo, chlorine is 0.005~0.010g / L in terms of chloride ion conversion, and these mixed electrolytes are set at a bath temperature of 18.5~ 28.5°C.

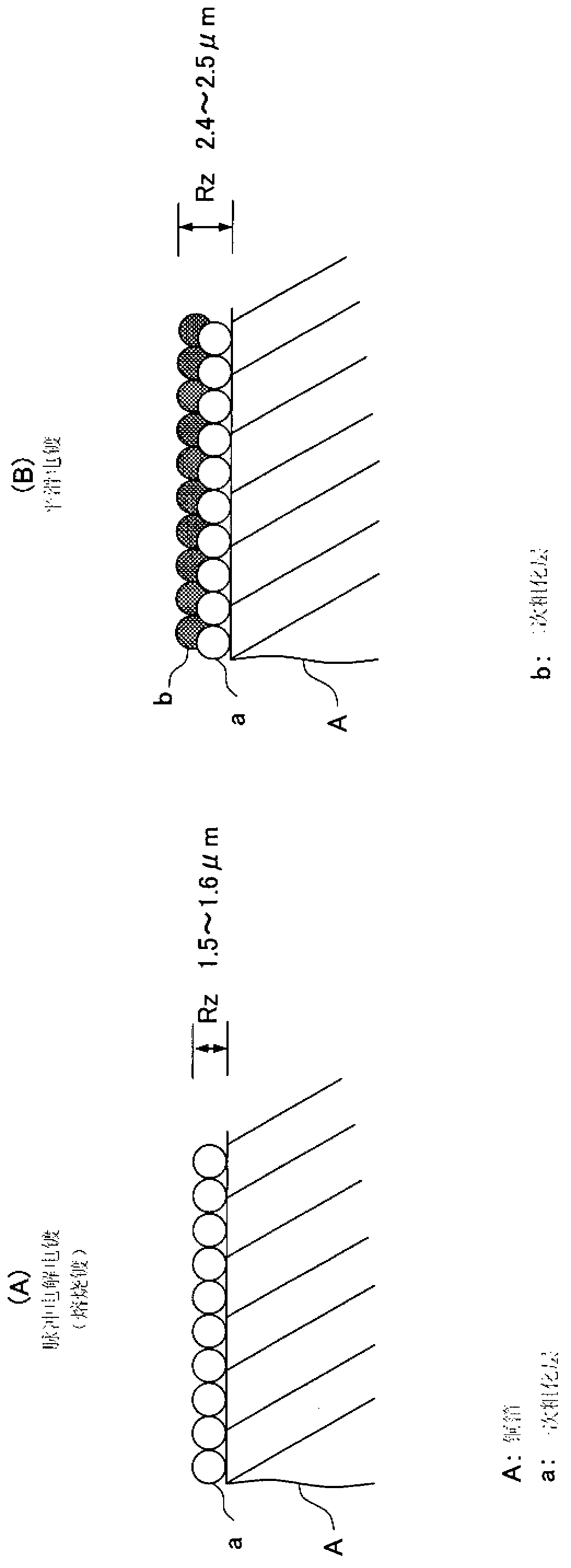

[0120] Pulse cathodic electrolytic plating treatment

[0121] Apply a pulsed current density between the power supply contact roller 7 and the iridium oxide anode 11, that is, set the pulsed cathodic electrolytic plating current density to, for example, 22 to 31.5 A / dm 2 .

[0...

Embodiment 1

[0152] As the base material, the following copper foil is used, the copper foil is composed of oxygen-free rolled copper A, the untreated rolled copper foil A having a thickness of 0.018 mm, in terms of surface roughness Rz specified in JIS-B-0601, Its surface roughness was 0.8 μm, and its elongation at room temperature (for example, 25° C.) was 6.2%. Roughening treatment was performed on both surfaces of this copper foil under the following conditions.

[0153] In this roughening treatment, it is divided into the roughening treatment carried out on the copper foil surface and the roughening treatment carried out on the back side of the copper foil separated by the shielding plate 13. The surface of the foil is roughened, and the back of the copper foil is roughened from the bottom to the outlet side of the tank. Regarding the current applied between the power supply contact roller 7 and the iridium oxide anode 11, the opening time is set to 10ms, and the closing time is 60ms ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com