Ethylene-propylene-diene monomer composition with limiting temperature of 175 DEG C for vehicle rubber pipe

A technology of automotive rubber hose and EPDM, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as poor heat resistance, achieve extended service life, low volatility, and prevent early burns burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] In parts by mass

[0023]

[0024]

[0025] According to the raw materials in the formula in the implementation list, the film is made into a film for testing and testing, and a kind of rubber hose for automobiles with a limit temperature of 175 degrees

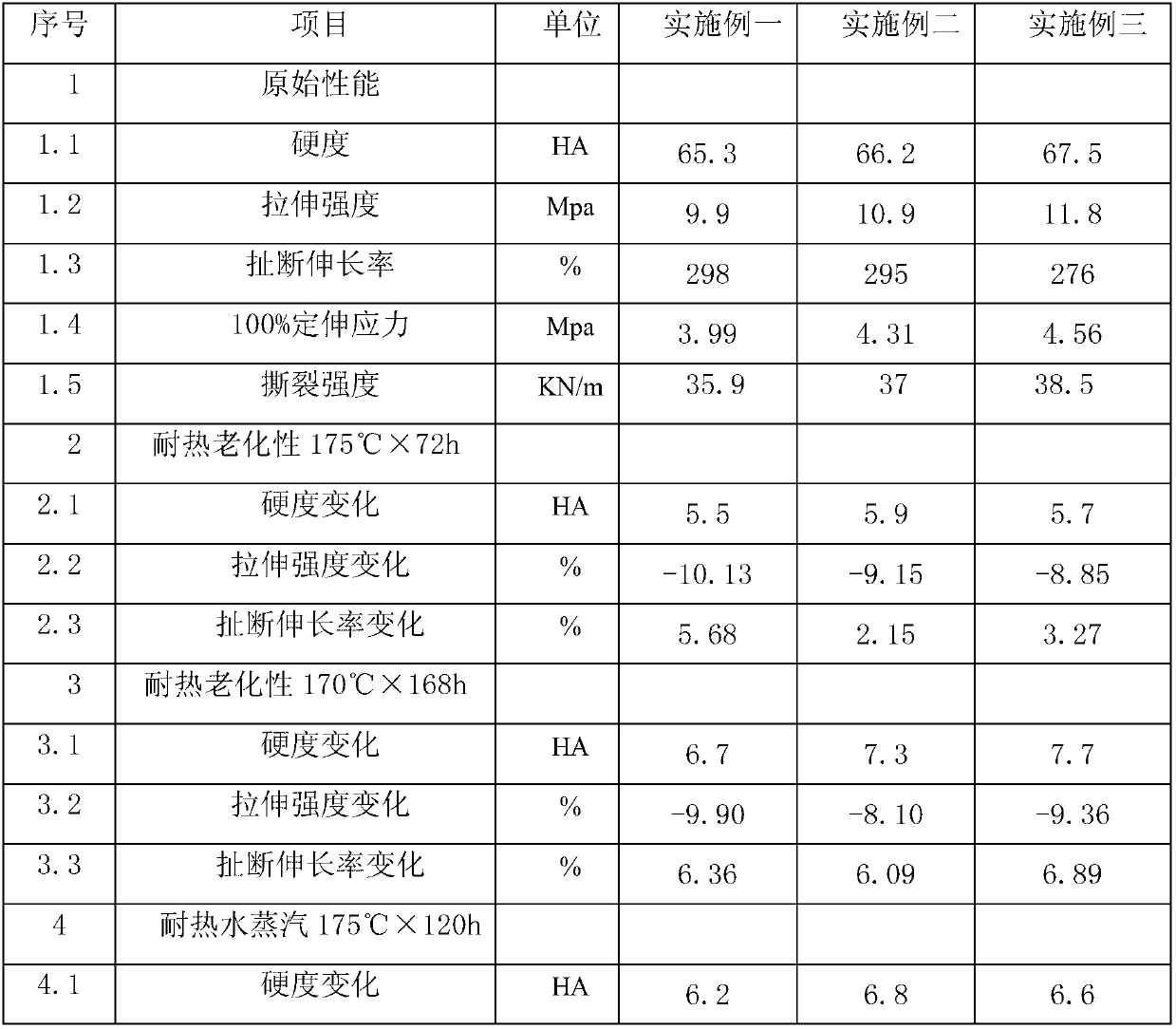

[0026] The performance comparison of the EPDM composition formula is as follows:

[0027]

[0028]

[0029] From the data in the above table, it can be concluded that the formulation of an EPDM composition used in automotive rubber hoses with a limit temperature of 175 degrees has excellent heat aging resistance and high temperature resistance, and the performance after 72 hours at a high temperature of 175 degrees is The reduction is small, the change in hardness is kept within 10, and the compression set after high temperature resistance is also low. At the same time, the performance retention rate after oil resistance is also very good, the volume change is within 100%, and the low temperature resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com