Crosslinked polyethylene pipe

A technology of cross-linked polyethylene and pipe body, which is applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of inability to use high water pressure, shorten service life, and difficult implementation of durability, so as to improve anti-oxidation The ability to degrade, prolong the service life, and increase the effect of tension resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

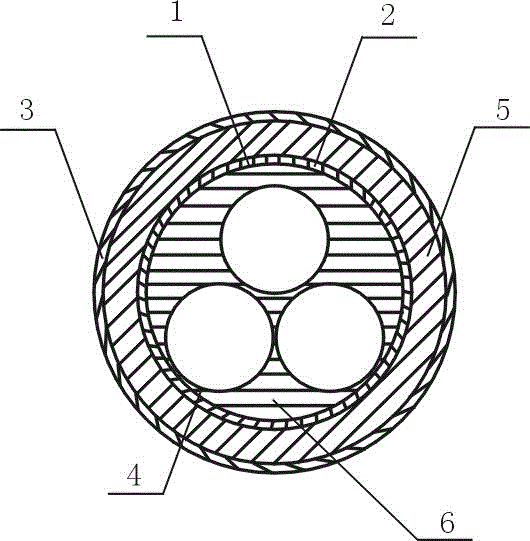

[0015] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0016] Such as figure 1 with figure 2 As shown, a cross-linked polyethylene pipe of the present invention includes a pipe body 1, a protective inner layer 2 and an outer layer 3, the pipe body 1 is equidistantly distributed along the axial direction with at least one through hole 4, and the protective inner layer A cross-linked intermediate layer 5 is provided on the outer wall of the cross-linked intermediate layer 5 , a sandwich wall 6 for partition is provided between the through holes 4 and adjacent through holes 4 , and an outer layer 3 is provided on the outer wall of the cross-linked intermediate layer 5 . There are three through holes 4 . Both the protective inner layer 2 and the cross-linked middle layer 5, and the cross-linked middle layer 5 and the outer layer 3 are bonded to each other to form an integral body. The cross-linked inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com