Organosilane crosslinked polyethylene composite tube

A polyethylene composite pipe and silane cross-linking technology, applied in the direction of pipes, rigid pipes, pipe protection, etc., can solve the problems of limited external tension of the pipe, difficult implementation of durability, poor antifreeze effect, etc., to disperse water pressure and improve performance , the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

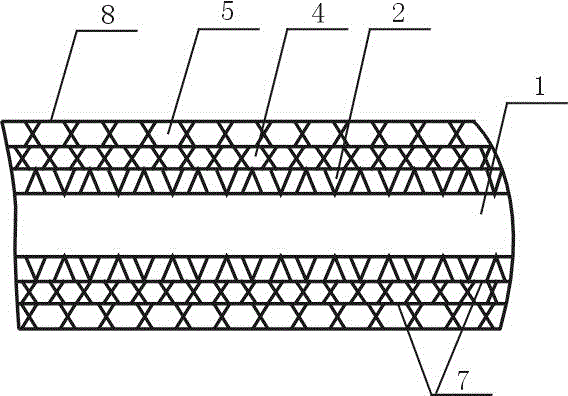

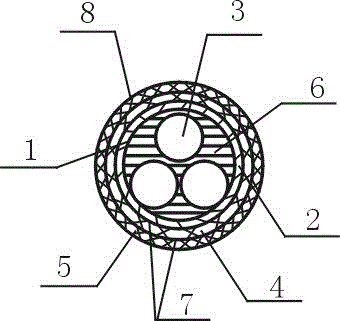

[0017] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0018] Such as figure 1 with figure 2 As shown, a silane cross-linked polyethylene composite pipe of the present invention includes a pipe body 1 and a silane cross-linked polyethylene inner layer 2, and at least one through hole 3 is arranged equidistantly in the pipe body 1 along the axial direction. 1. A silane cross-linked polyethylene inner layer 2 is arranged on the inner wall. A thermoplastic structural layer 4 is compositely extruded on the outer wall of the silane cross-linked polyethylene inner layer 2. A foaming insulation layer 5 is compounded on the outer wall of the thermoplastic structural layer 4. Through holes 3 Between the adjacent through-holes 3 is provided a clamping wall 6 for partition. The thermoplastic structural layer 4 adopts polyolefin polymer or its blend with inorganic substances or its nanoscale polymer, or polyviny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com