Aluminum clamping pressure pipe

A pressure tube and through-hole technology, which is applied in the field of clamped aluminum pressure tubes, can solve problems such as easy deformation, cracking, and limited external tension of the tube, and achieve the effect of dispersing water pressure, offsetting external tension, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

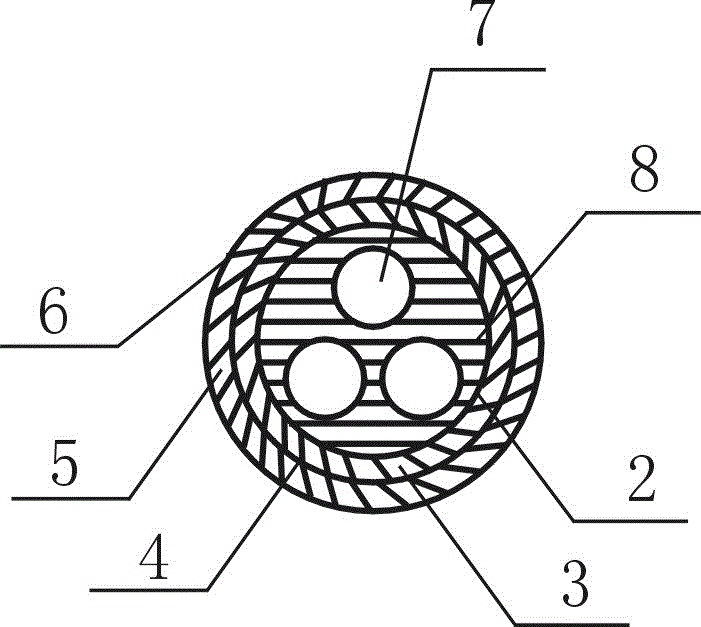

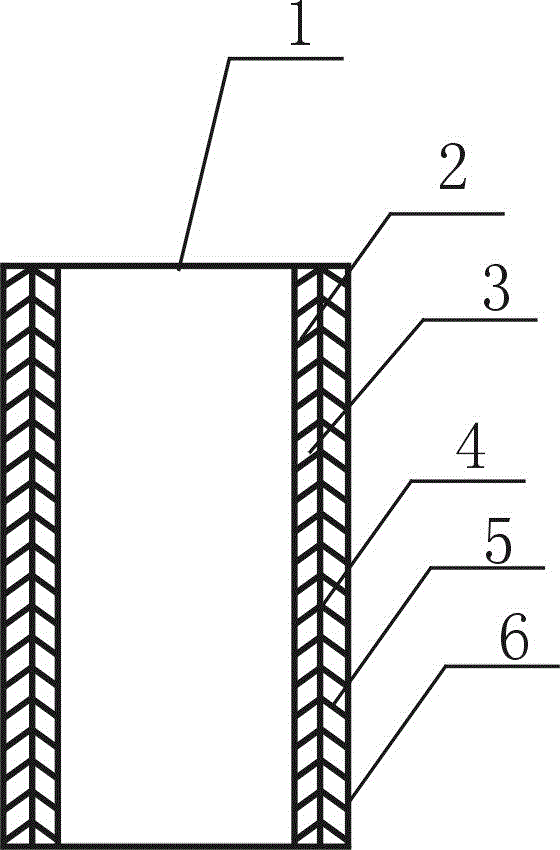

[0017] like figure 1 and figure 2 As shown, a kind of clamped aluminum pressure pipe 1 of the present invention comprises the following layer structure, the first layer is the inner layer 2, the second layer is the hot melt adhesive layer 3, the third layer is the skeleton layer 4, and the fourth layer is the heat Melt glue layer 5, the fifth layer is the outer layer 6. The inner layer 2 is made of polyethylene material, and the outer layer 6 is made of three-type random copolymerized polypropylene material. At least one through-hole 7 is arranged equidistantly along the axial direction in the aluminum-clamped pressure tube 1 . Between the through hole 7 and the adjacent through hole 7 is provided a clamping wall 8 for partition. There are three through holes 7 .

[0018] The aluminum-clamped pressure pipe of the present invention can with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com