Novel polyethylene tube

A polyethylene pipe, a new type of technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems where the water pressure cannot be used, the implementation is difficult, the pipes are easy to corrode, etc. The effect of increasing the pressure, improving heat resistance, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

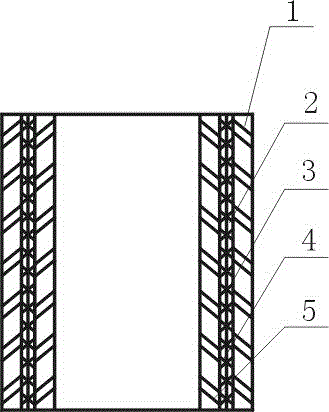

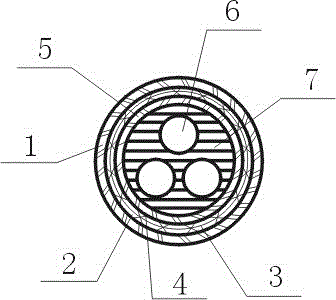

[0015] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0016] Such as figure 1 and figure 2 As shown, a novel polyethylene pipe of the present invention includes the following layer structure, the first layer is the outer layer 1 of the pipe, the second layer is the hot melt adhesive layer 2, the third layer is the aluminum skeleton layer 3, and the fourth layer It is a hot melt adhesive layer 4, and the fifth layer is an inner layer 5 of a polyethylene pipe. At least one through-hole 6 is equidistantly distributed in the axial direction in the new polyethylene pipe, and a clamping wall 7 is arranged between the through-hole 6 and the adjacent through-hole 6 for separation. The outer diameter of the new polyethylene pipe is φ10-160mm, and the thickness is: the outer layer of the pipe is 1-40mm; the inner layer of the polyethylene pipe is 1-20mm; the aluminum skeleton layer is 0.1-5mm; the hot-melt ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com