Thermoplastic elastomer particle for dish washing machine and preparation method

A thermoplastic elasticity, dishwasher technology, applied in the field of dishwasher sealing materials and preparation, can solve the problems of poor compensation of EPDM rubber materials, unstable vulcanization and foaming processes, and easy bulging of sealing strips. Good mechanical properties, improved anti-oxidative degradation performance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

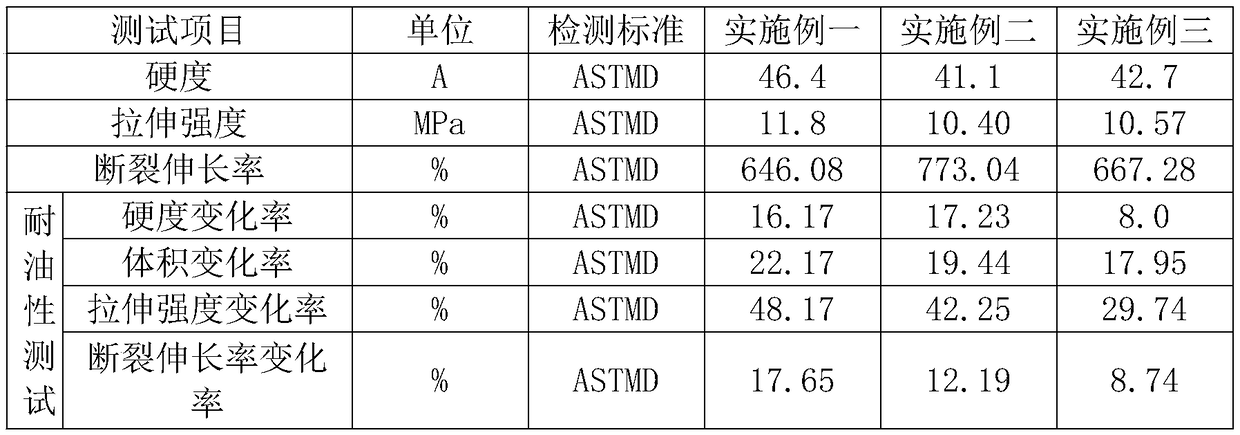

Examples

preparation example Construction

[0020]Adopt above-mentioned a kind of preparation method that is used for dishwasher thermoplastic elastomer granule, its concrete steps are:

[0021] Step 1: Weighing: Accurately weigh each component according to the range of parts in claim 1;

[0022] Step 2: Mix evenly: put the accurately weighed hydrogenated styrene-butadiene block copolymer and extender oil into the high-speed mixer according to the range of parts in claim 1, and set the speed of the high-speed mixer to 500 -800r / min, mixing time is 10min, in the material after this mixing is completed, add according to the scope of the number of parts in claim 1, polypropylene after accurate weighing, ethylene-vinyl acetate copolymer, filler, pigment, anti- Oxygen, lubricant and antifungal agent. At this time, the speed of the high-speed mixer is set to 1000-1500r / min, and the mixing time is 5min. Mix evenly to obtain the material;

[0023] Step 3: Granulation: Put the materials uniformly mixed in Step 2 into a twin-scr...

Embodiment 1

[0026] A kind of thermoplastic elastomer granule for dishwasher is weighed (weight) according to the following material parts among the present invention:

[0027] (Table 1:)

[0028] Hydrogenated Styrene-Butadiene Block Copolymer

110 copies

Homopolypropylene

30 copies

100 copies

Antioxidant: 1010

0.3 parts

Lubricant: silicone masterbatch

2 copies

1 copy

Antifungal agent: DCOIT

0.3 parts

60 copies

4 parts

Pigment: Ultramarine

0.03 parts

[0029] Put the hydrogenated styrene-butadiene block copolymer and extender oil accurately weighed according to (Table 1:) into the high-speed mixer, the speed of the high-speed mixer is set to 500-800r / min, and the mixing time is 10min. Add the accurately weighed polypropylene, ethylene-vinyl acetate copolymer, fillers, pigments, antioxidants, lubric...

Embodiment 2

[0033] (Table 2:)

[0034] Hydrogenated Styrene-Butadiene Block Copolymer

100 copies

random copolymer polypropylene

30 copies

Ethylene-vinyl acetate copolymer

20 copies

filler oil

150 copies

Antioxidant: DSTDP

1 copy

4 parts

Antifungal agent: DCOIT

0.3 parts

30 copies

2 copies

[0035] Put the hydrogenated styrene-butadiene block copolymer and extender oil accurately weighed according to (Table 2:) into the high-speed mixer, the speed of the high-speed mixer is set to 500-800r / min, and the mixing time is 10min. Add the polypropylene, ethylene-vinyl acetate copolymer, filler, pigment, antioxidant, lubricant and anti-fungal agent according to (Table 2:) and accurately weigh to the mixed material. The speed of the mixer is set to 1000-1500r / min, the mixing time is 5min, and the material is obtained by mixing even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com